Well bore fluid redistribution and fluid disposal

a technology of fluid redistribution and well bore, which is applied in the direction of fluid removal, wellbore/well accessories, sealing/packing, etc., can solve the problems of insufficient production of water from the formation, affecting gas desorption, and inhibiting the flow of gas out of the coal seam, so as to reduce the cost of regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]The various disclosed features of the present invention should not be construed to limit the present invention to only certain embodiments. Furthermore, this description should be understood to support and encompass all the various embodiments of the invention, such as each method, process, device, apparatus, assembly, and business disclosed, and of each of the elements or steps of such embodiments, either alone or in combination, such as may be presented in the claims that serve as part of this disclosure.

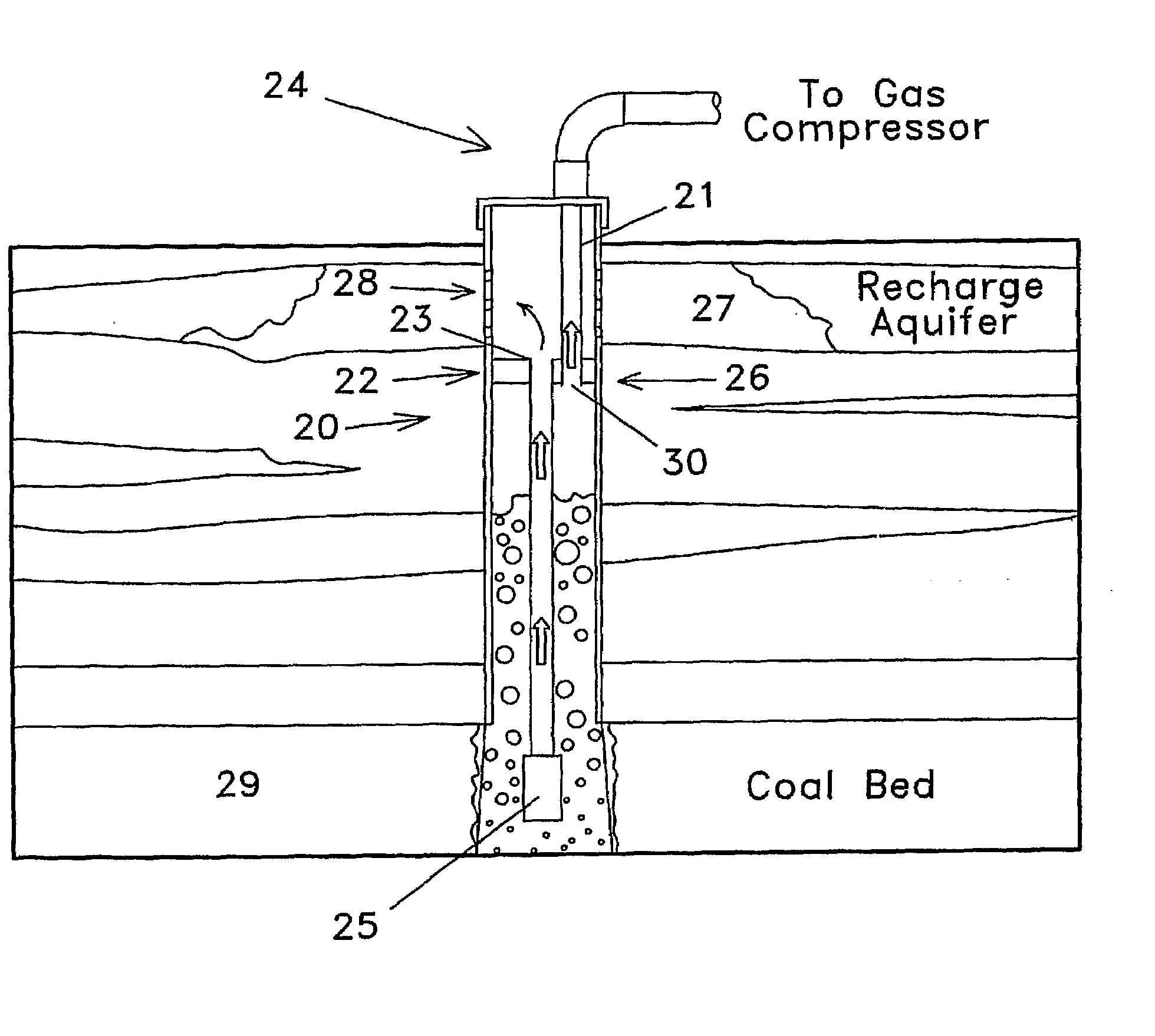

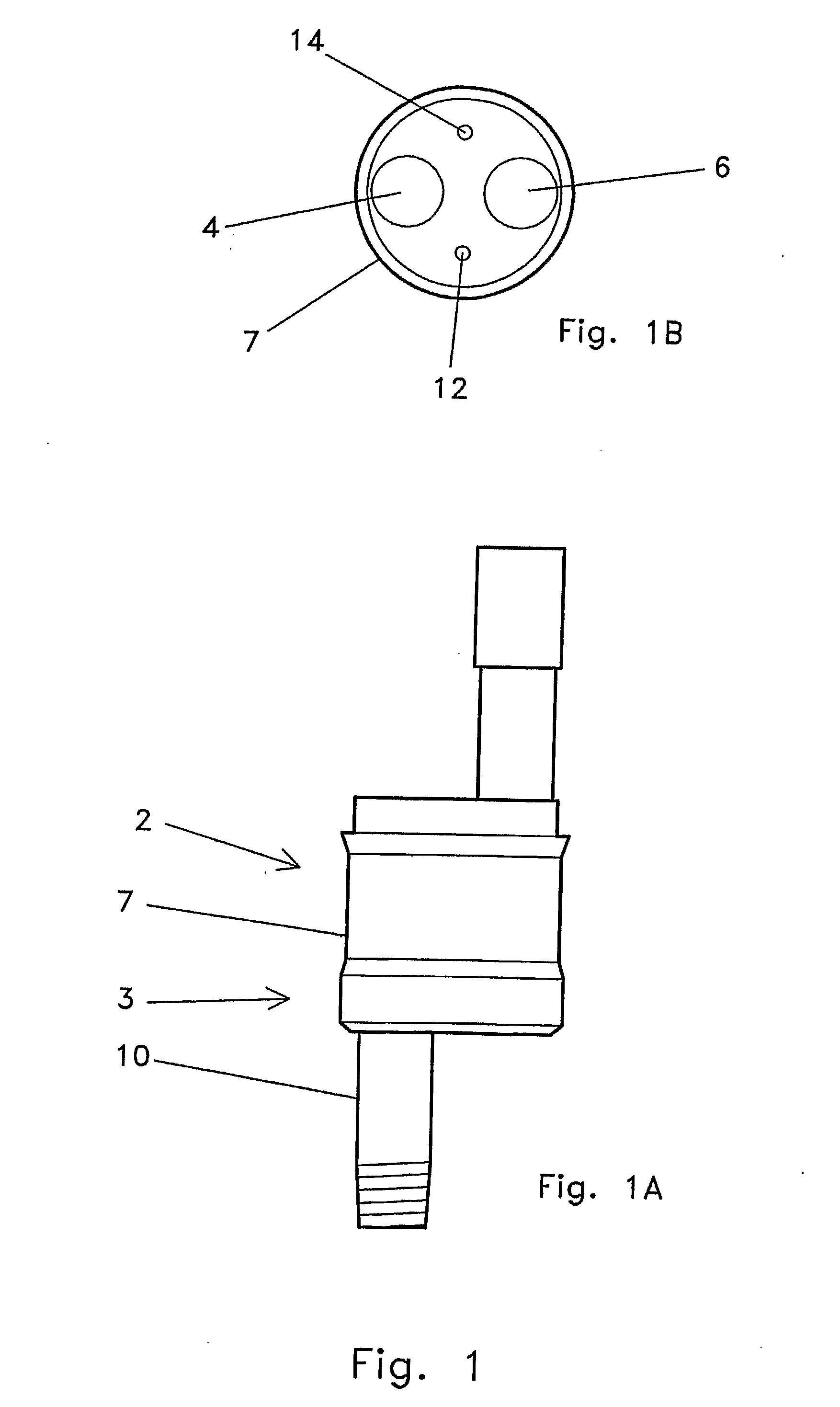

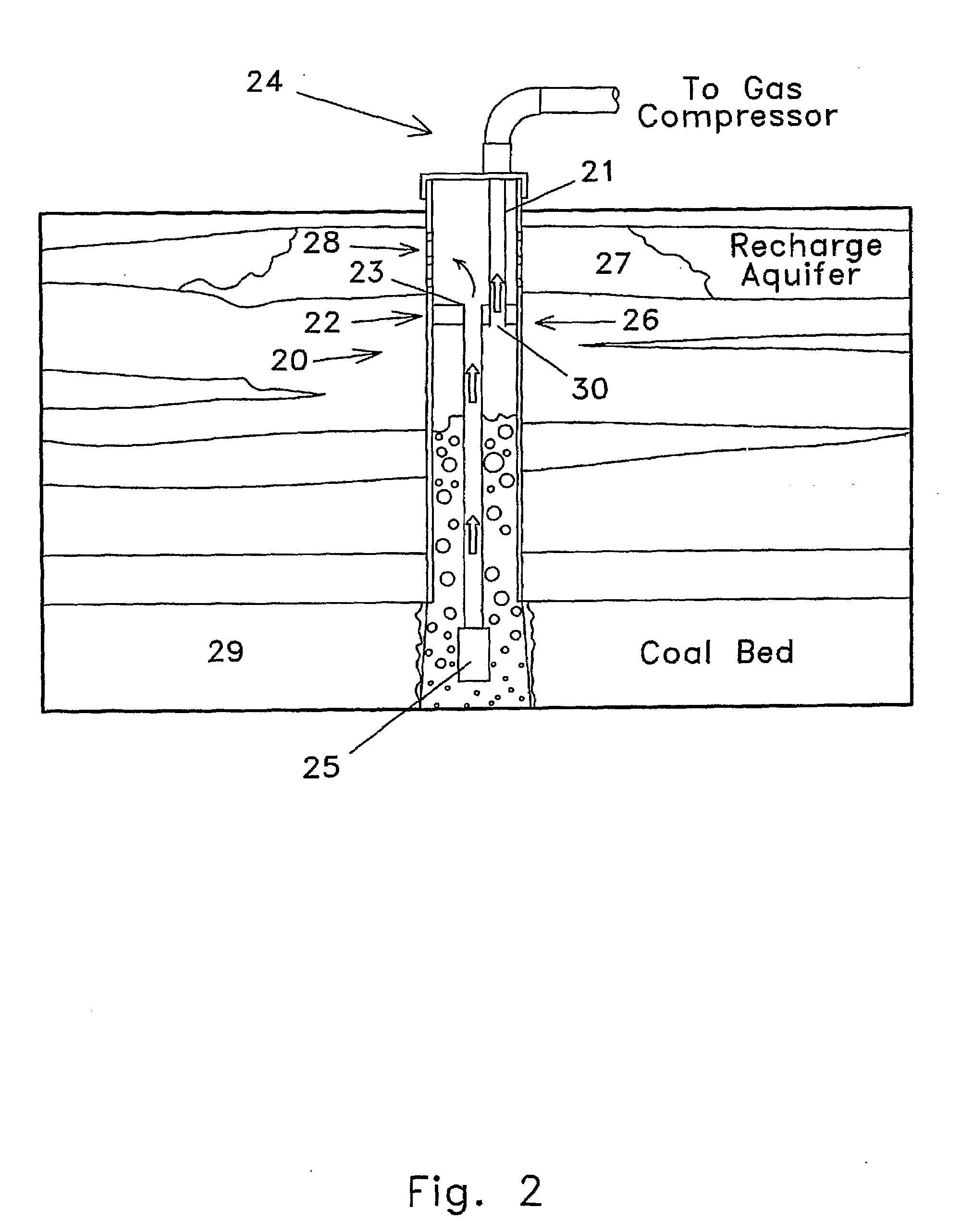

[0030]Disclosed are one or more processes, methods, apparatus, assembly, and business that relate to concepts of redistribution of fluids in well bore environments. In certain embodiments, such techniques may allow for new functionality and even multiple functionality of a coal bed methane well. In some embodiments, such new functionality and even multiple functionality may include use of a well, such as a coal bed methane well or a petroleum oil and gas well, and as what ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com