Garbage bin lid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

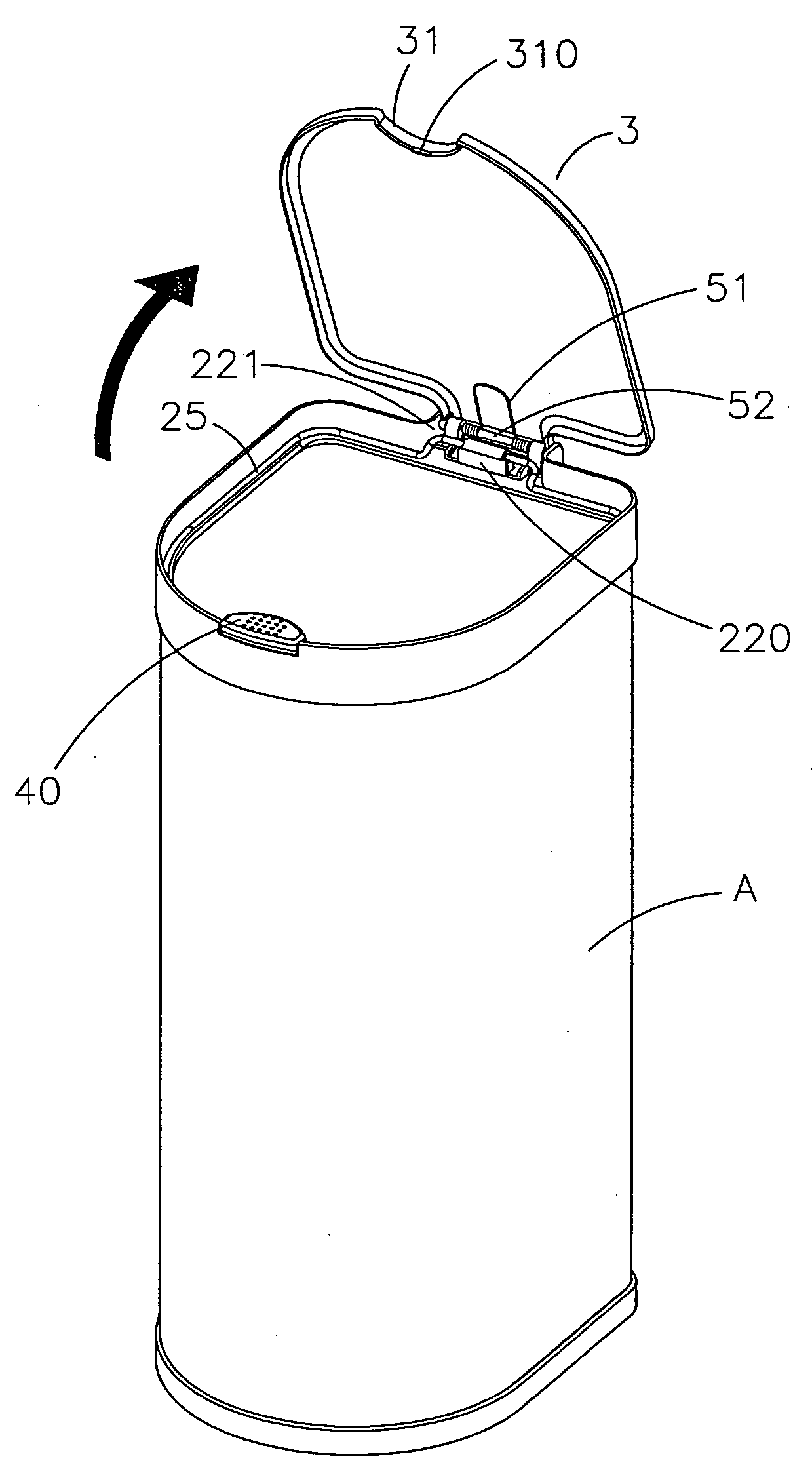

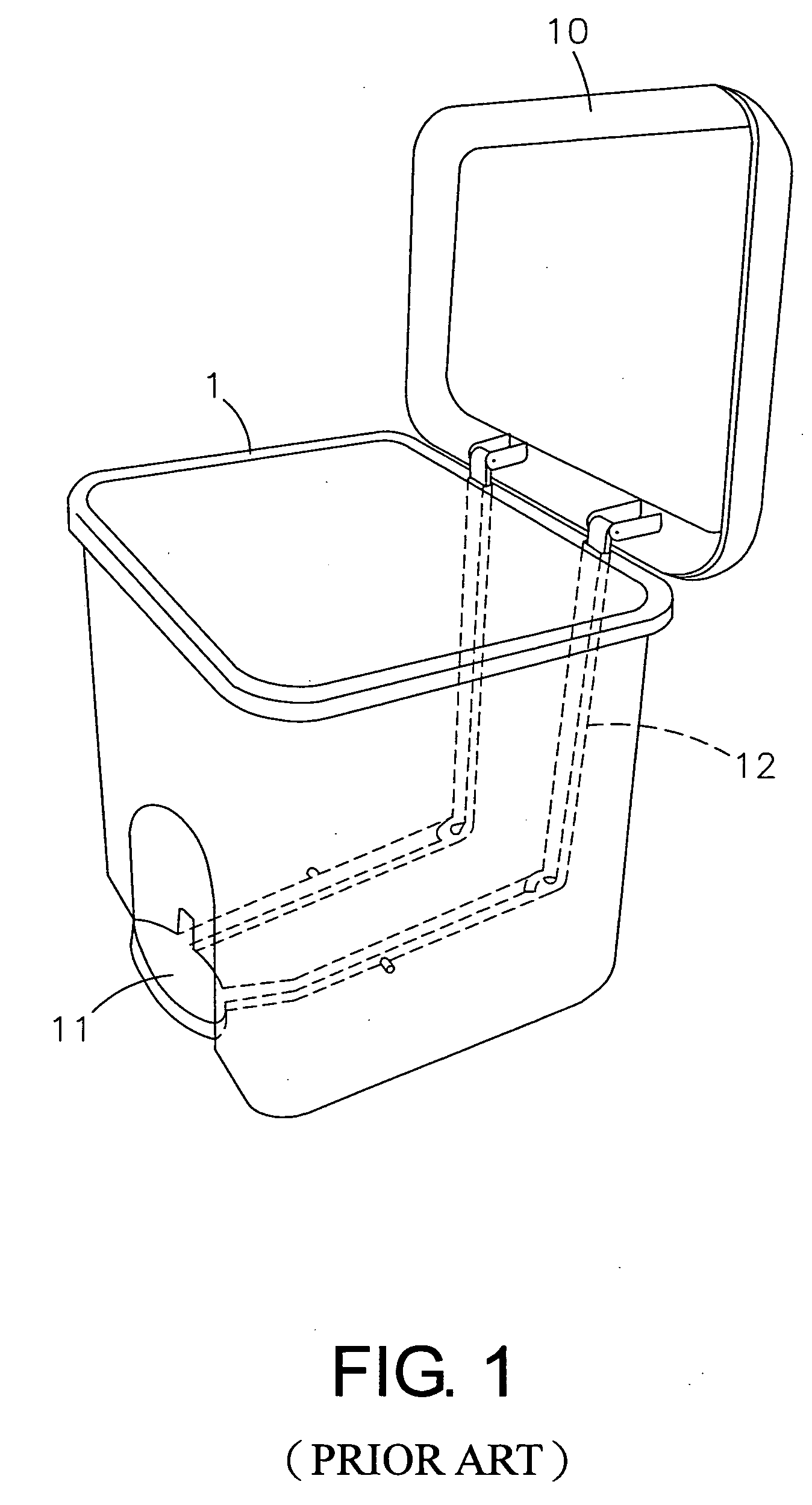

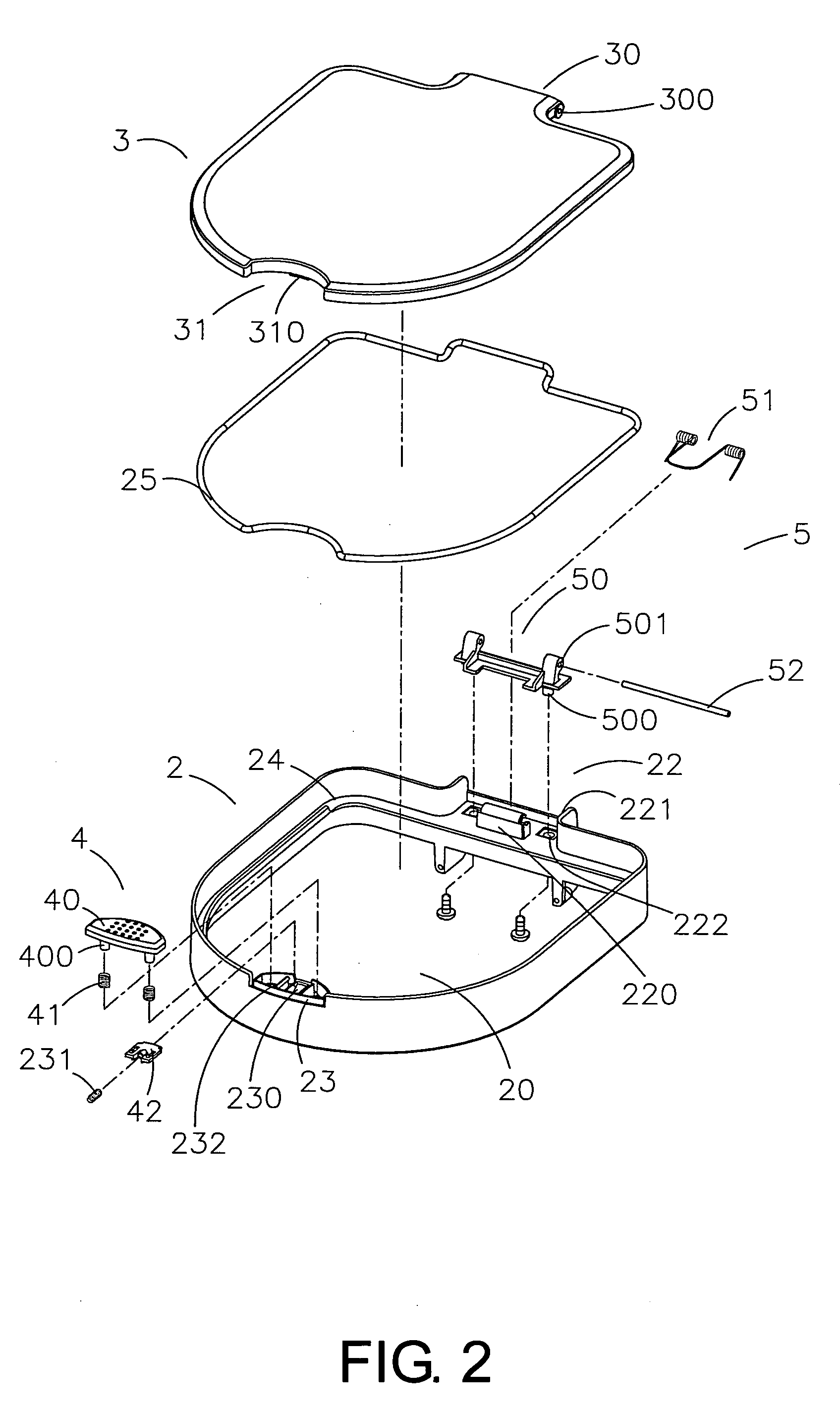

[0015]As shown in FIGS. 2˜8, a preferred embodiment of a garbage bin lid the in the present invention includes a lid frame 2, a lid 3, a lid open-and-close unit 4 and a joining unit 5.

[0016]The lid frame 2 has an opening 20 and a fixing member 21 on the edge. On one end of lid frame 2 is a pivotal aperture 22. Opposite pivotal aperture 22 is a lid open-and-close unit base 23. Pivotal aperture 22 has a pivot base 220, pivotal aperture wall 221 and two sliding grooves 222. On lid open-and-close unit base 23 there are a sliding groove 230, a spring 231 and positioning hole 232 and there is an inlay groove 24 on the inside of the lid frame 2. Sealing strip 25 is inlaid in inlay groove 24 allowing the lid 3 and lid frame 2 to close tightly.

[0017]The lid 3 is attached to the opening 20 of the lid frame 2. One end of lid 3 has a pivot-connecting base 30 protruding. The other end has a fitting curve 31. On the front of fitting curve 31 there is an engaging member 310. Pivot-connecting base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com