Method for converting a household cleaning appliance with a non-bulk dispensing system to a household cleaning appliance with a bulk dispensing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

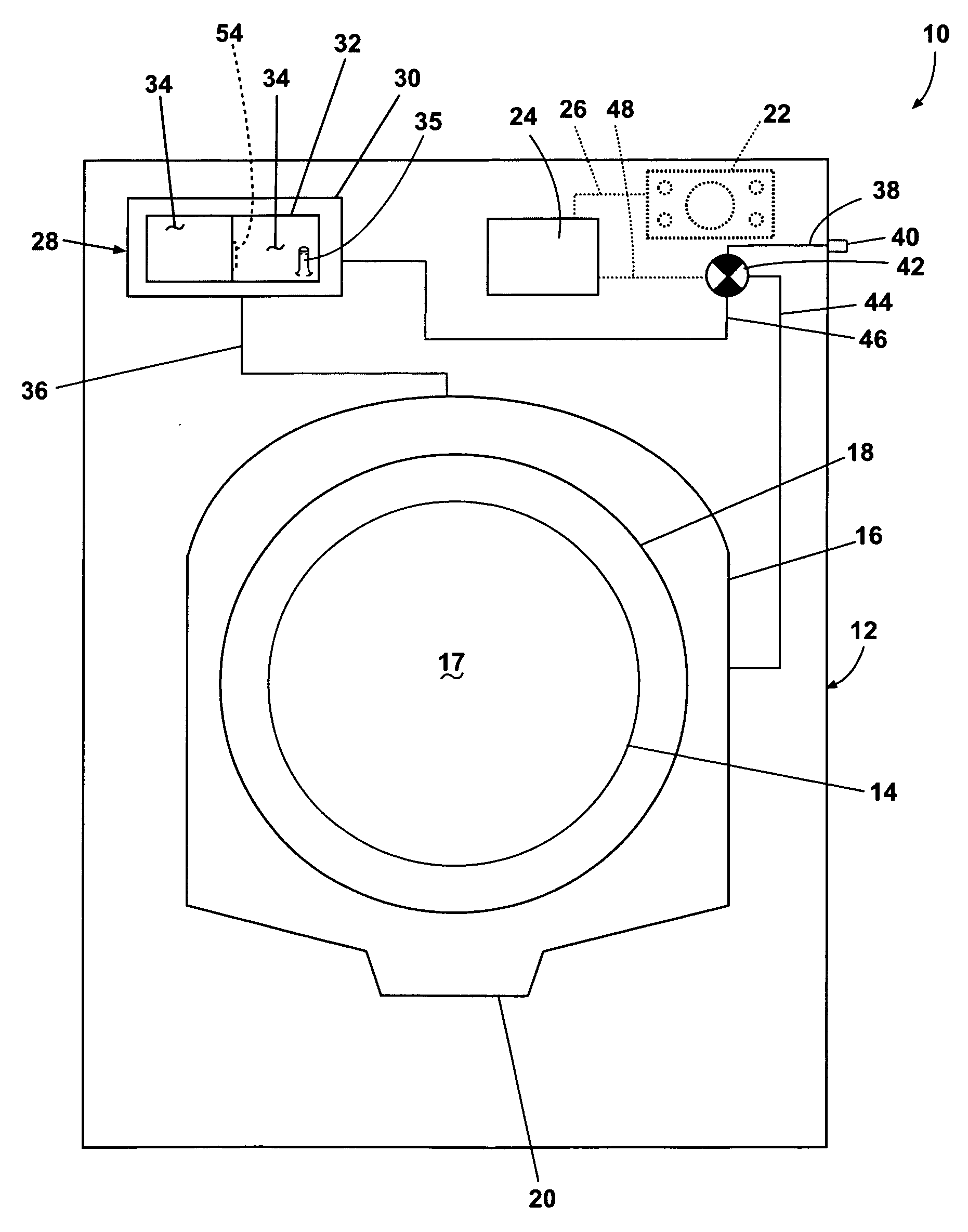

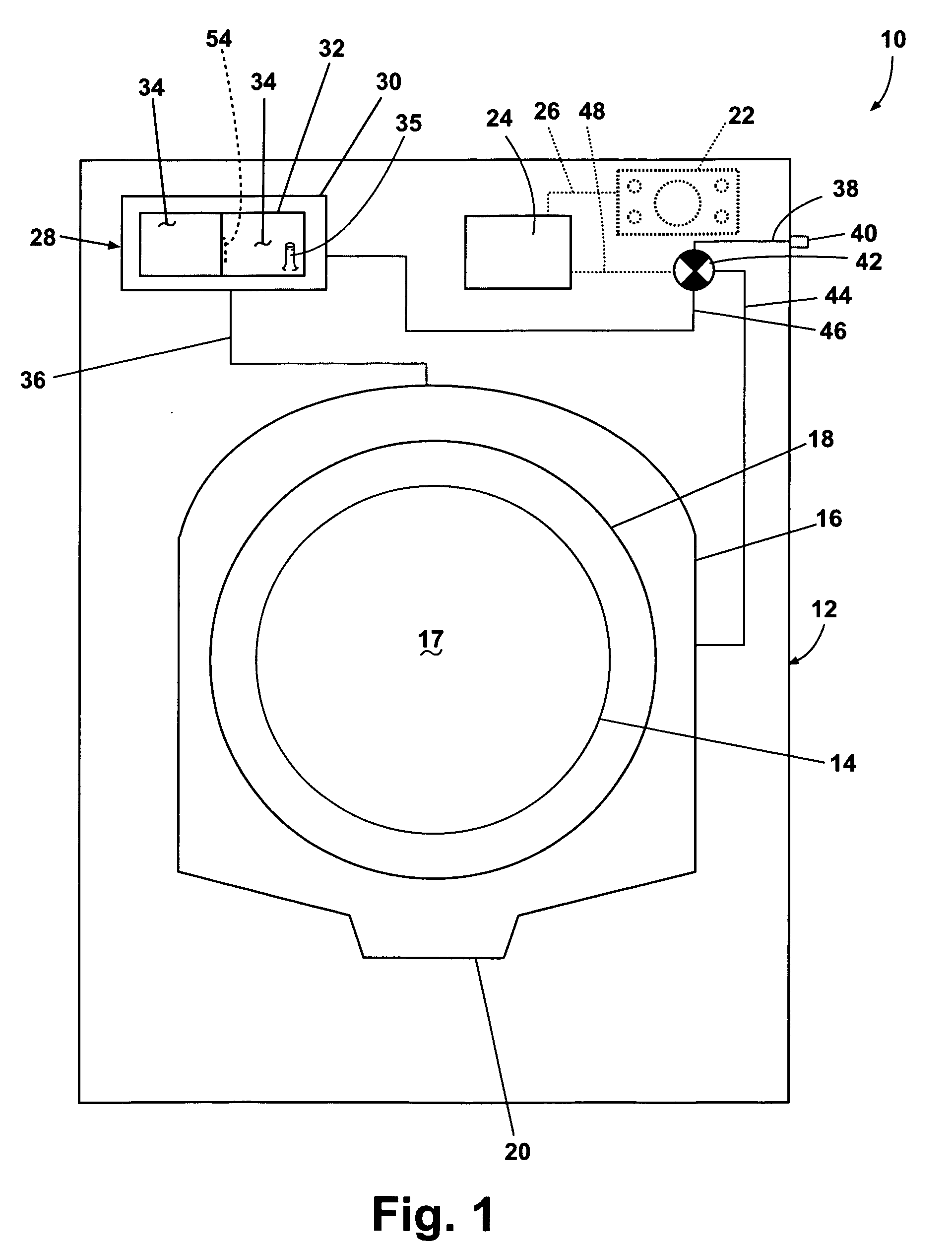

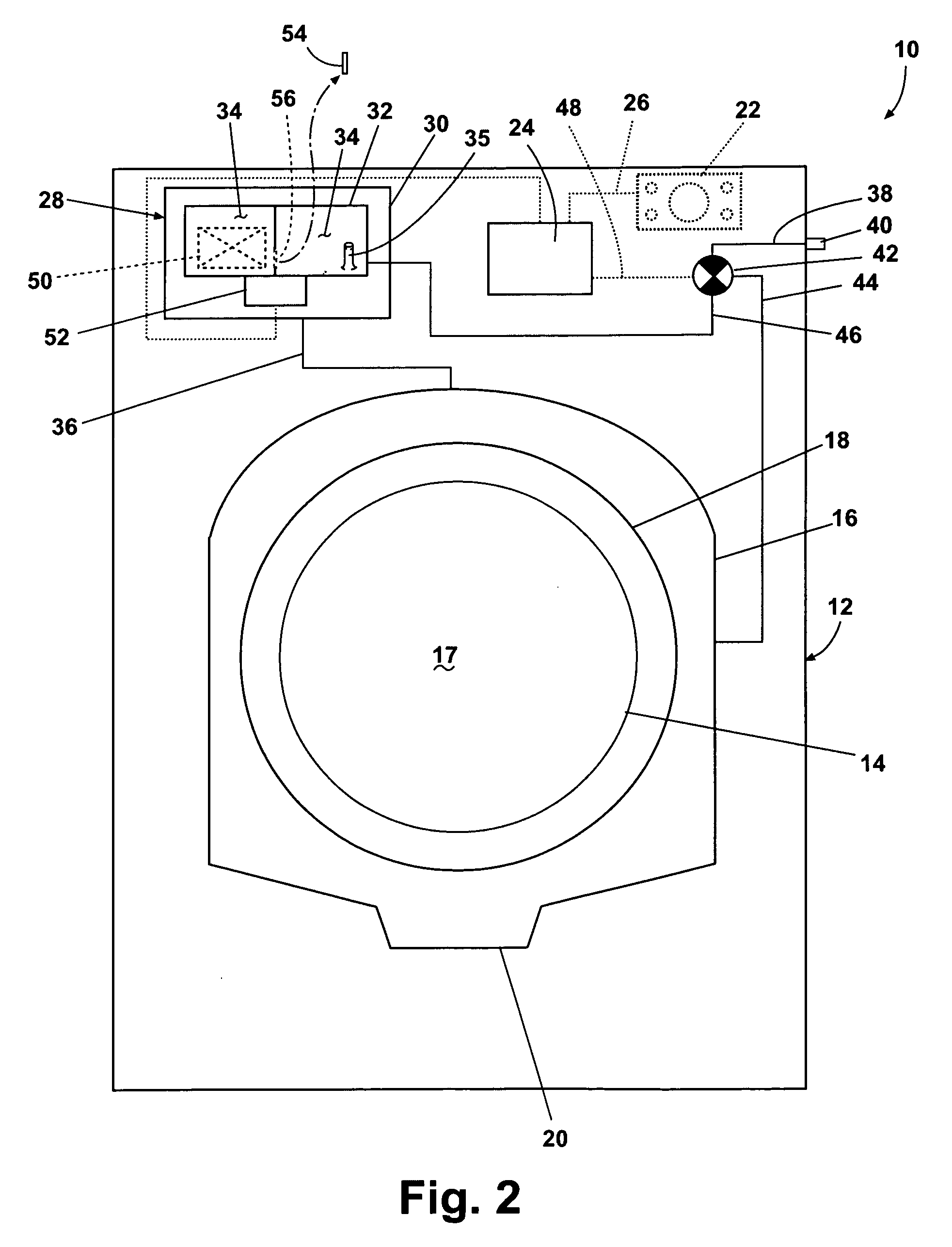

[0012]Referring now to FIG. 1, a first embodiment of the invention may be illustrated as a cleaning appliance in the environment of a horizontal axis automatic clothes washing machine 10. Although much of the remainder of this application will focus on the embodiment of an automatic clothes washing machine 10, the invention may have utility in other environments, including other cleaning appliances, especially in dishwashers. The automatic clothes washing machine 10 shares many features of a conventional automated clothes washer, which will not be described in detail herein except as necessary for a complete understanding of the invention. The invention may also be utilized in other fabric treatment appliances such as a dryer, such as a tumble dryer or a stationary dryer, or a combination washing machine and dryer.

[0013]Further, washing machines may be typically categorized as either a vertical axis washing machine or a horizontal axis washing machine. While there are situations whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gravity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com