Micro-domain graphitic materials and method for producing same

a graphitic material and micro-domain technology, applied in the field of micro-domain graphitic materials and methods for producing same, can solve the problems of limited diffusion of absorption process and low production yield, and achieve the effect of large yield ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

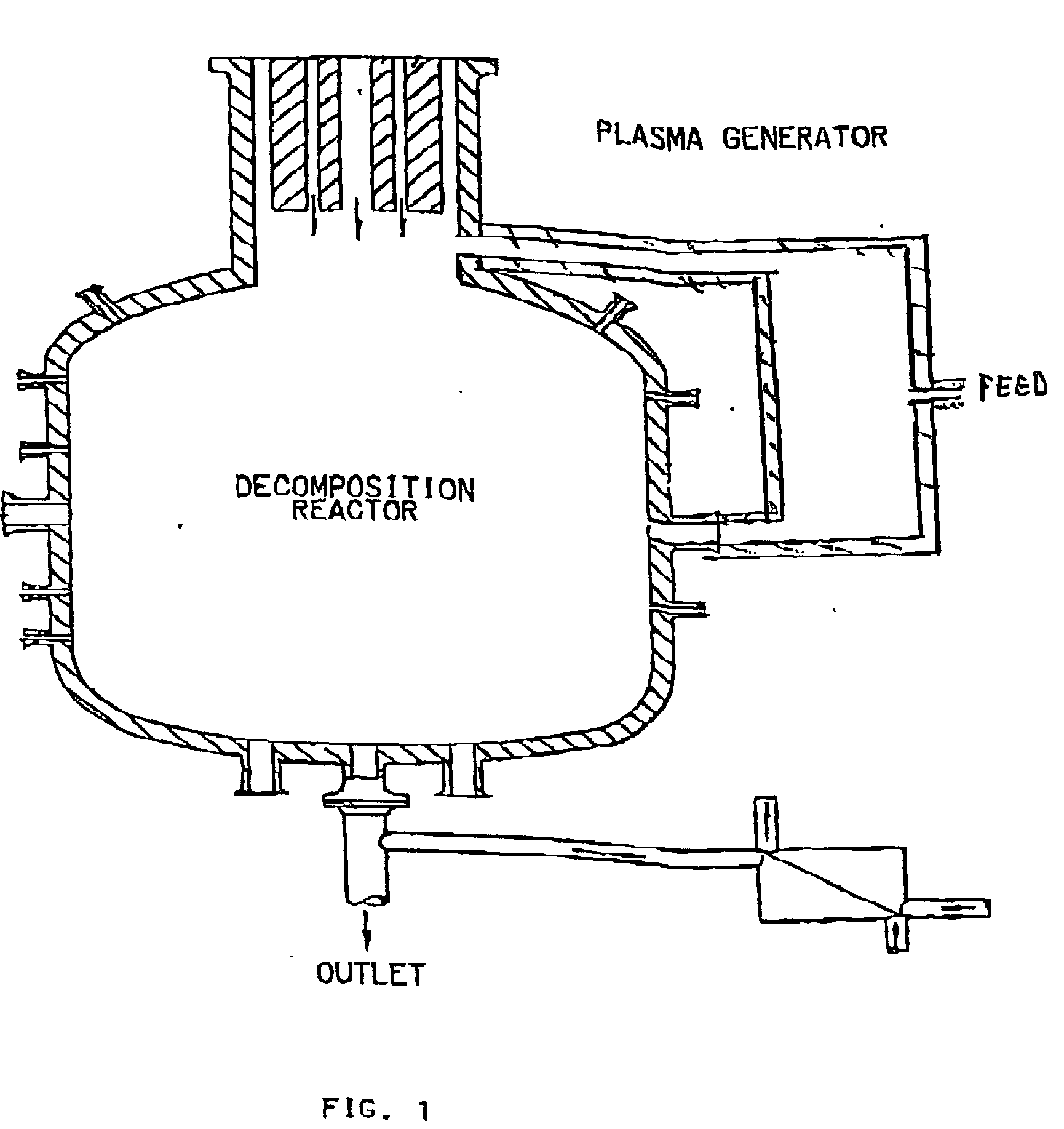

[0031]Heavy fuel oil was heated to 1600° C. and introduced in the reactor by use of the self-invented axial aligned nozzle at a feed rate of 67 kg per hour. The reactor pressure was kept at 2 bar. Hydrogen was employed as plasma gas, and the plasma gas feed rate was 350 Nm3 / h, while the gross power supply from the plasma generator was 620 kW. This resulted in a plasma gas enthalpy of 1.8 kWh / Nm3 H2. The time elapsed from the atomized oil was introduced until the product left the reactor was approximately 0.23 seconds.

[0032]The resulting carbon black was traditional amorphous of N-7xx quality. The volatile content of the carbon black was measured to 0.6%.

example 2

[0033]In this example the oil feed rate, the hydrogen plasma gas enthalpy as well as the residence time was tuned in such a direction that the evaporated hydrocarbons did not achieve pyrolysis temperature during the first cycle. The residence time of the hydrocarbons during the first cycle through the reactor was minimized by increasing the oil and plasma gas feed rate.

[0034]Heavy fuel oil was heated to 160° C. and introduced in the reactor by use of the self-invented axial aligned nozzle at a feed rate of 115 kg per hour. The reactor pressure was kept at 2 bar. The hydrogen plasma gas feed rate was 450 Nm3 / h, while the gross power of supply from the plasma generator was 1005 kW. This resulted in plasma gas enthalpy of 2.2 kWh / Nm3H2. The time elapsed from the oil was introduced until the PAHs left the reactor was approximately 0.16 seconds.

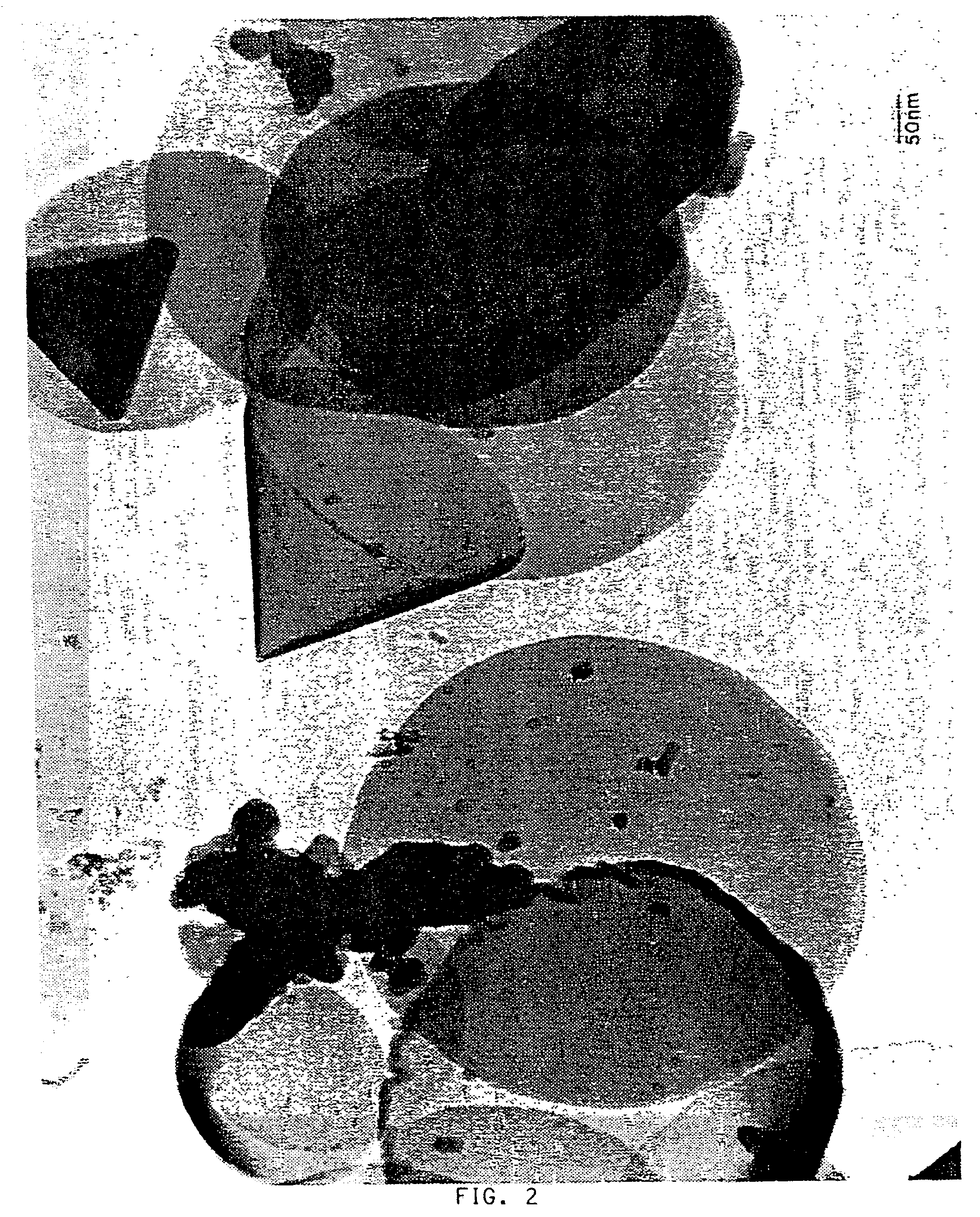

[0035]The resulting PAHs were reintroduced into the reactor in the plasma-are zone to produce a micro-domain graphitic material, with a yield hig...

PUM

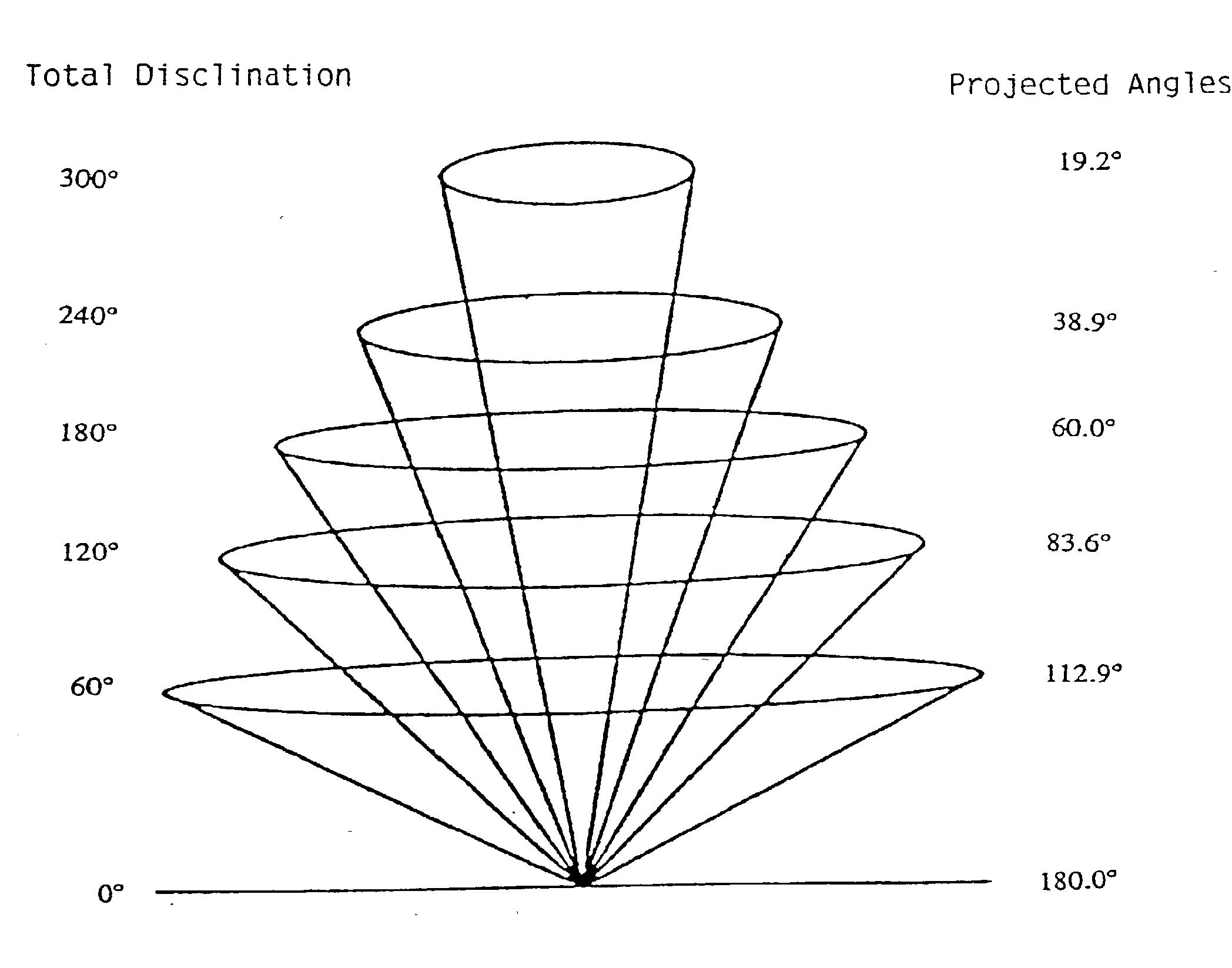

| Property | Measurement | Unit |

|---|---|---|

| cone angles | aaaaa | aaaaa |

| cone angles | aaaaa | aaaaa |

| cone angles | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com