Screen Assembly for a Shale Shaker

a technology of shale shaker and assembly, which is applied in the direction of screening, moving filter element filters, and screening, etc., can solve the problems of time-consuming workshop process, and achieve the effect of increasing the overall and increasing the rigidity of the panel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

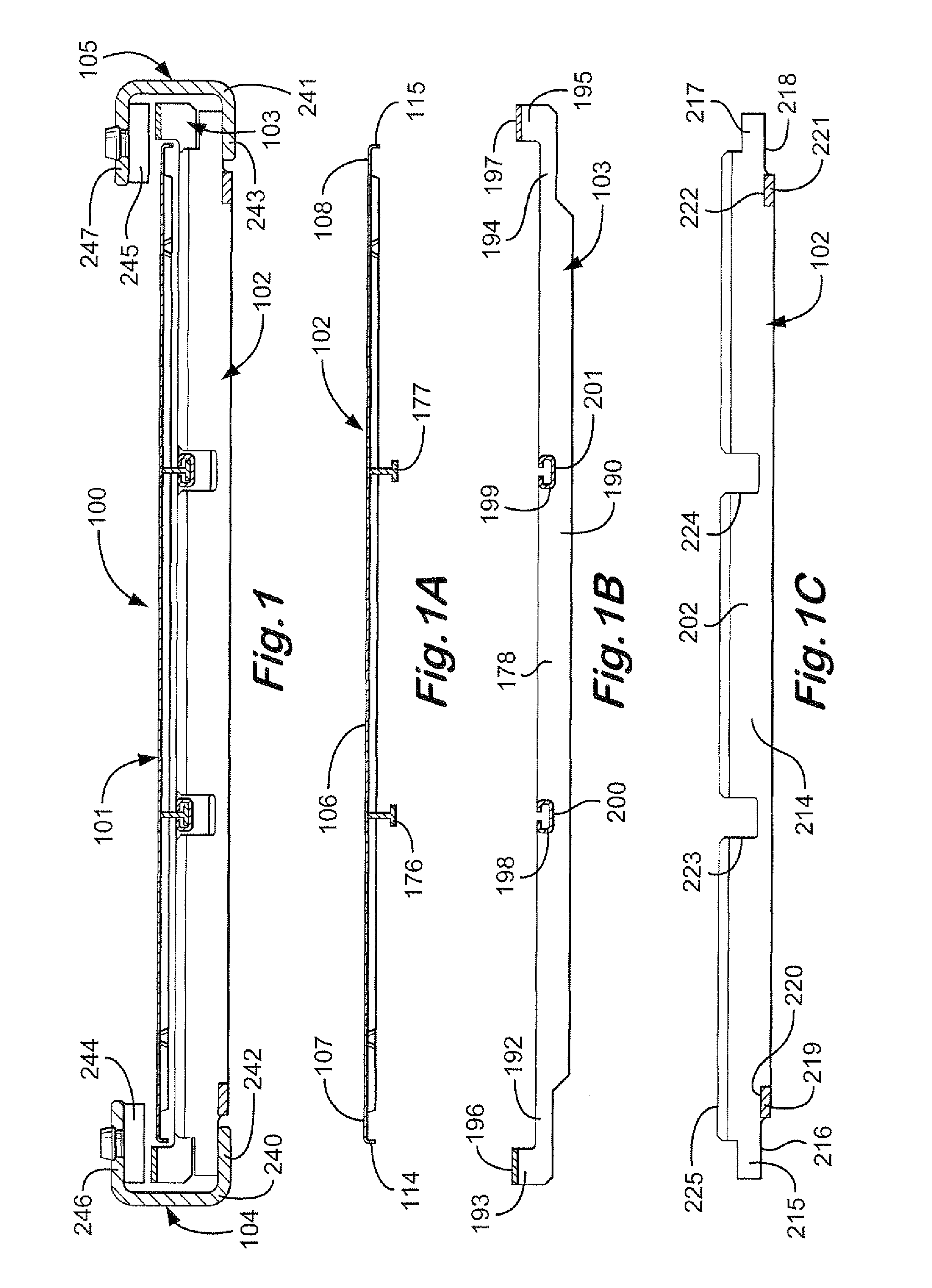

[0062]Referring to FIG. 1, there is shown a screen assembly, generally identified by reference numeral 100. The screen assembly 100 comprises a panel 101, a support structure 102 and a pull down member 103. In use, the panel 101 would have at least one layer of screening material adhered or otherwise attached thereto. Typically, each layer of screening material comprises a layer of wire mesh. Typically, the panel 101 would have three layers of screening material lying one over the other, the lowermost layer of screening having larger openings and larger wires. In use, the screen assembly 100 is arranged in clamping rails 104 and 105 of a shale shaker.

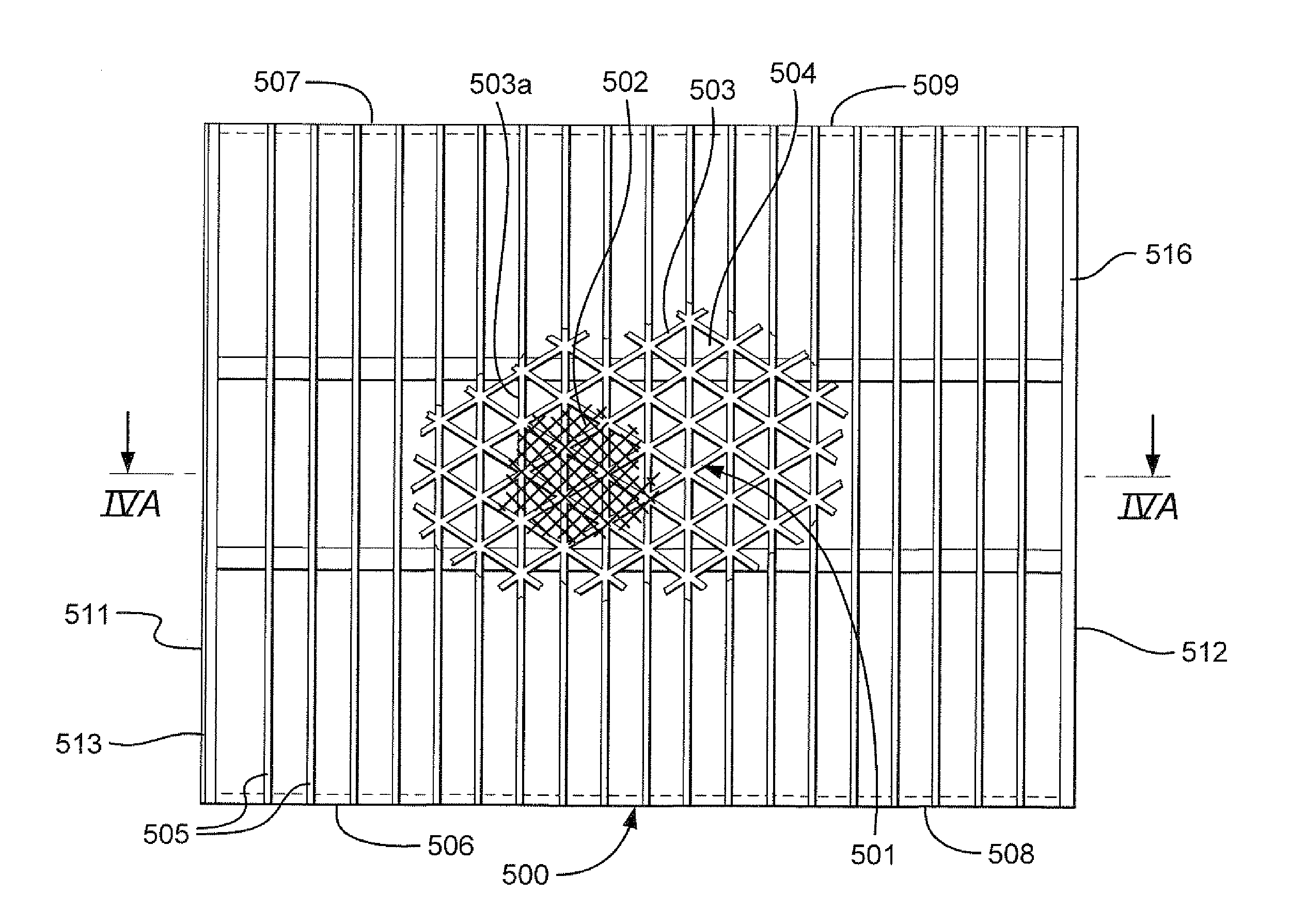

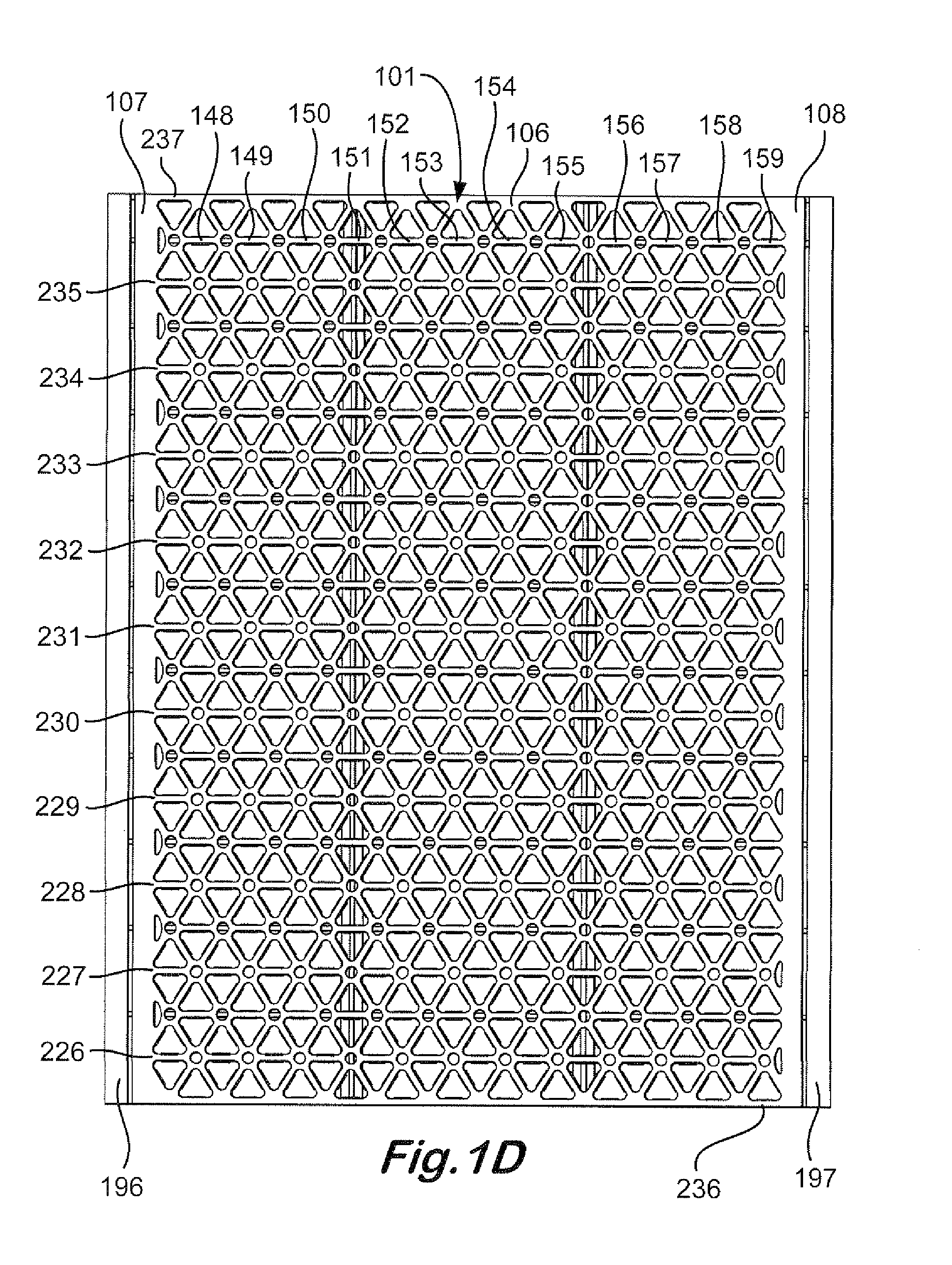

[0063]Referring to FIGS. 1A, 1D and 1G, the panel 101 is made from a 1.5 mm mild steel plate. The panel 101 comprises an area 106 provided with a plurality of apertures, a left side portion 107 provided with no apertures and a right side portion 108 provided with no apertures. The plurality of apertures in area 106 comprises a plurality...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com