Longitudinal heap handling system and method

a technology of long-term heaps and handling systems, applied in the direction of roads, road cleaning, roads, etc., can solve the problems of adding to increasing the cost of operation, so as to reduce the cost of replacing, less encumbrance of ditches, and less cost of maintenance of non-paved roads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

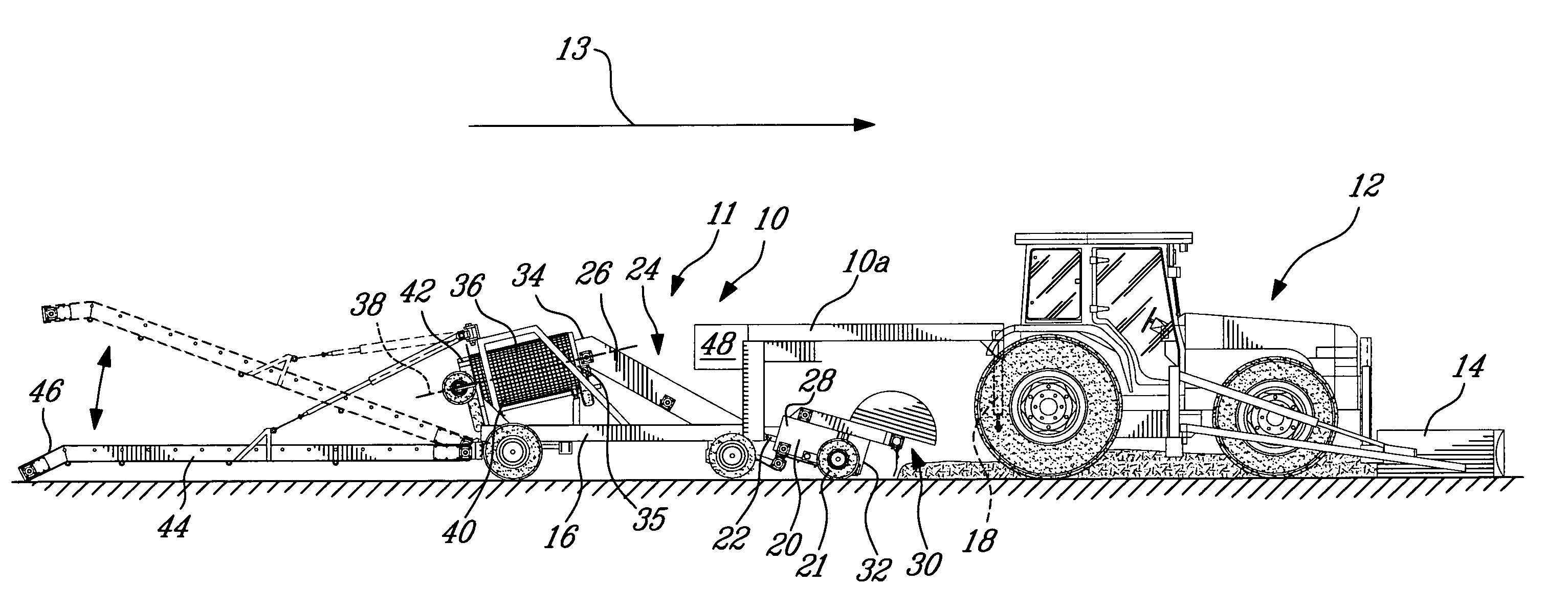

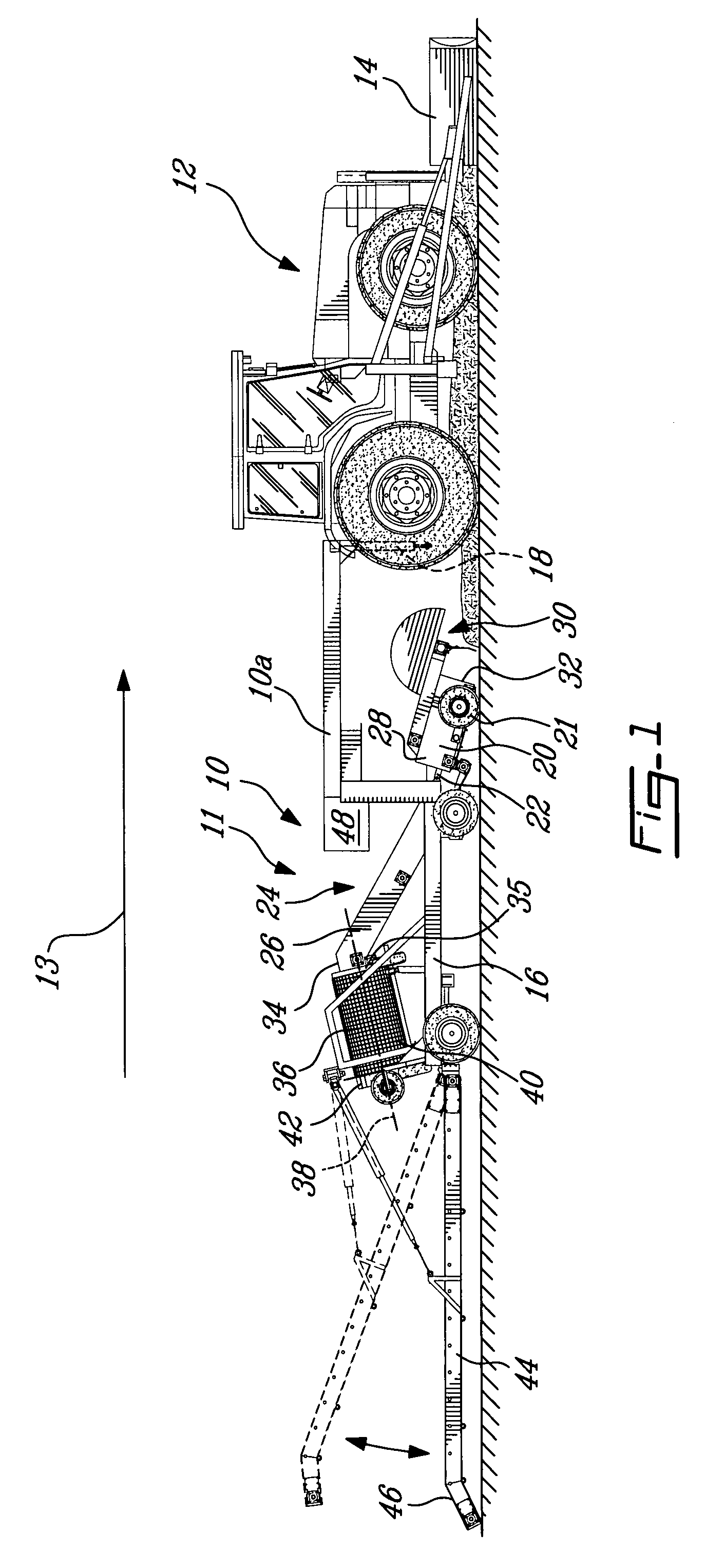

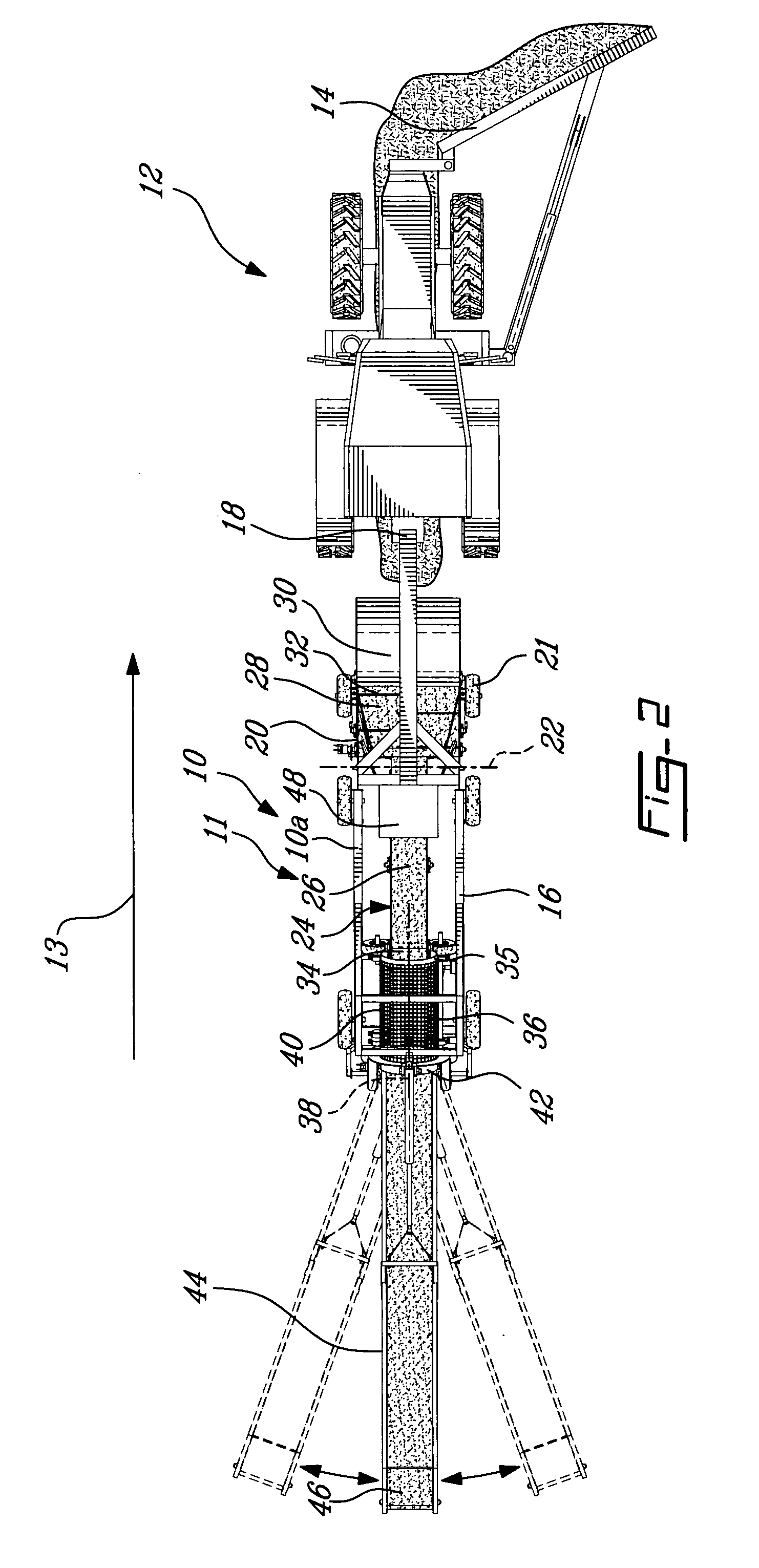

[0030]FIG. 1 shows a vehicle 10 which carries a system 11 for handling a longitudinal heap of material. In this example, the vehicle 10 is a trailer 10a. The trailer 10a is shown being towed by a tractor 12 for displacement in a longitudinal direction 13. The tractor 12 has a grading blade 14 which can be used to remove a surface layer of earthen material from a non-paved road surface, such as a non-paved shoulder of a paved or non-paved road, and form a longitudinal heap with the removed earthen material. The trailer 10a has a wheeled frame body 16 having a trailer hitch 18 at the front. It also has a mobile frame portion 20 pivotally mounted to the frame body 16 at a transversal and horizontal frame pivot axis 22. The mobile frame portion 20 is supported on two wheels, which are longitudinally offset from the frame pivot axis 22.

[0031]The system 11 includes a conveyor 24. In this example, the conveyor has two sections, or portions: a rear section 26 mounted to the frame body 16, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com