Devices and methods for translating tubular members within a well bore

a technology of tubular members and wells, applied in the direction of wellbore/well accessories, earthwork drilling and mining, etc., can solve the problems of prone to caving in and sloughing off, prone to slipping, and the drill string tends to become stuck in these areas, so as to effectively free the tubular string from a stuck condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]FIG. 1 illustrates a wellbore 10 that has been drilled from drilling rig 12 on the surface 14 downward through earth 16 and formation zones 18, 20, 22. The wellbore 10 has a deviated portion 24. It is noted that, while the deviated portion 24 is shown as being substantially horizontal, it may be angled in other directions as well. The wellbore 10 has a cased portion 26 proximate the surface 14 and an uncased portion 28.

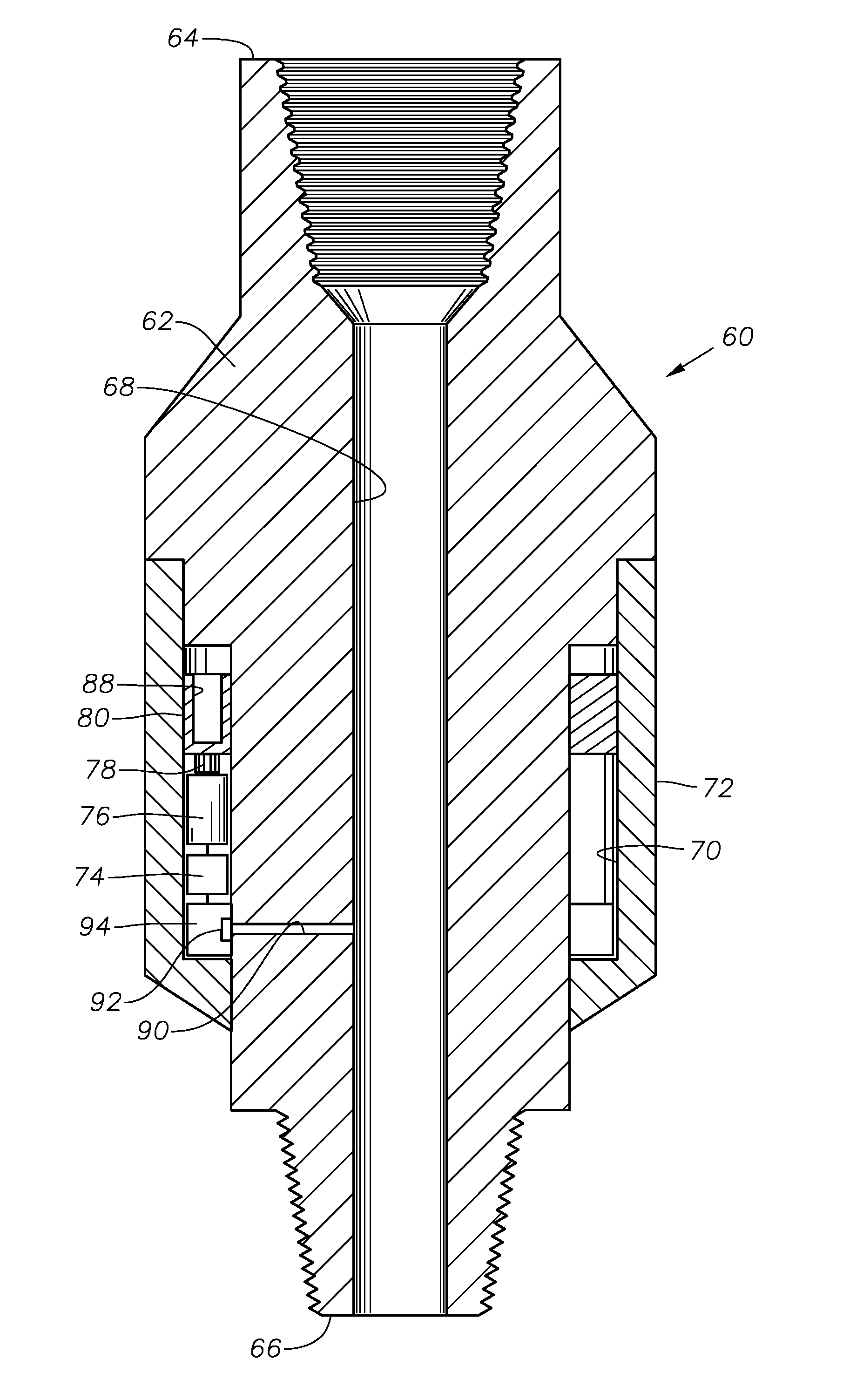

[0017]A tubular string in the form of a drill string 30 is disposed within the wellbore 10 and includes a plurality of drill string sections 32, 34, 36, 38, 40 that are secured together in a manner well known in the art. An axial fluid flowbore 42 is defined along the length of the drill string 30. The lower end of the drill string 30 carries a bottom hole assembly (BHA) 44 with drill bit. Vibration subs 46, 48, 50, 52 are incorporated within the drill string 30 in between each adjacent sections of the drill string 30. Although FIG. 1 illustrates a vibration sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com