Paint brush with collection reservoir

a paint brush and reservoir technology, applied in the field of handles, can solve the problems of inability to meet the ergonomic needs of users, inability to properly handle the handle of paint brushes, and inability to reduce the stress on muscles and ligaments of the hand, so as to reduce the stress on muscles and ligaments, reduce fatigue, and minimize the dripping of paint on the handle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]The following detailed description should be read with reference to the drawings, in which like drawings are numbered identically. The drawings depict the selected embodiment and are not intended to limit the scope of the invention. It will be understood that embodiments shown in the drawings and described below are merely for illustrative purposes, and are not intended to limit the scope of the invention as defined in the claims.

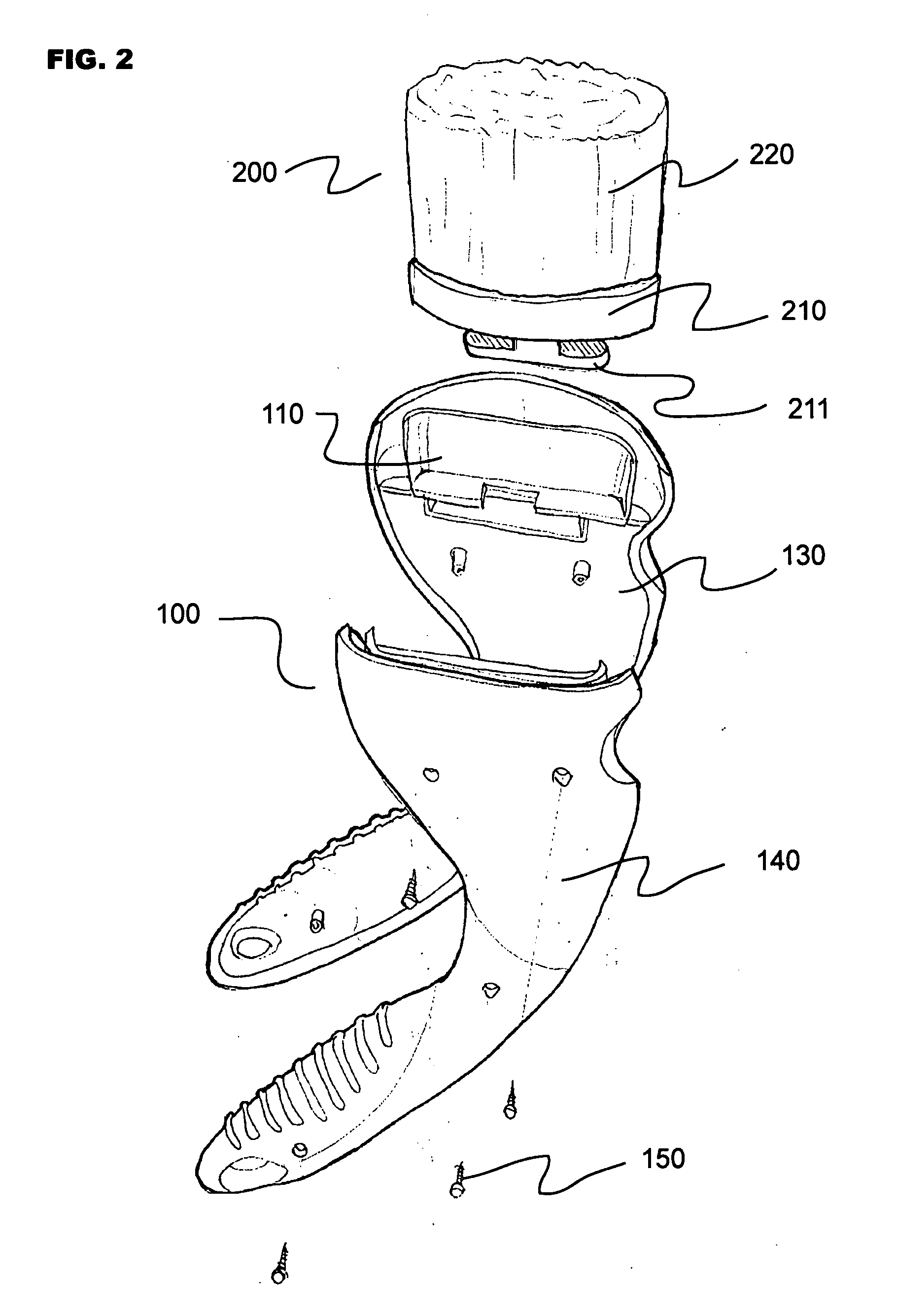

[0041]FIG. 1 is a perspective view of a handle 100 having an integrated reservoir 110 and a brush bristle assembly 200 fastened to the handle in accordance with the embodiment of the invention.

[0042]FIG. 2 is an exploded perspective view of the handle having an integrated reservoir with brush bristle assembly in accordance with an alternative embodiment of the invention. In the alternative embodiment shown, the handle 100 with integrated reservoir 110 may be formed of injection molded plastic and is a two-part design with a right half 130 and left hal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com