Compact well pumping unit actuated by linear motor with counterweight directly attached to slider

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Overview:

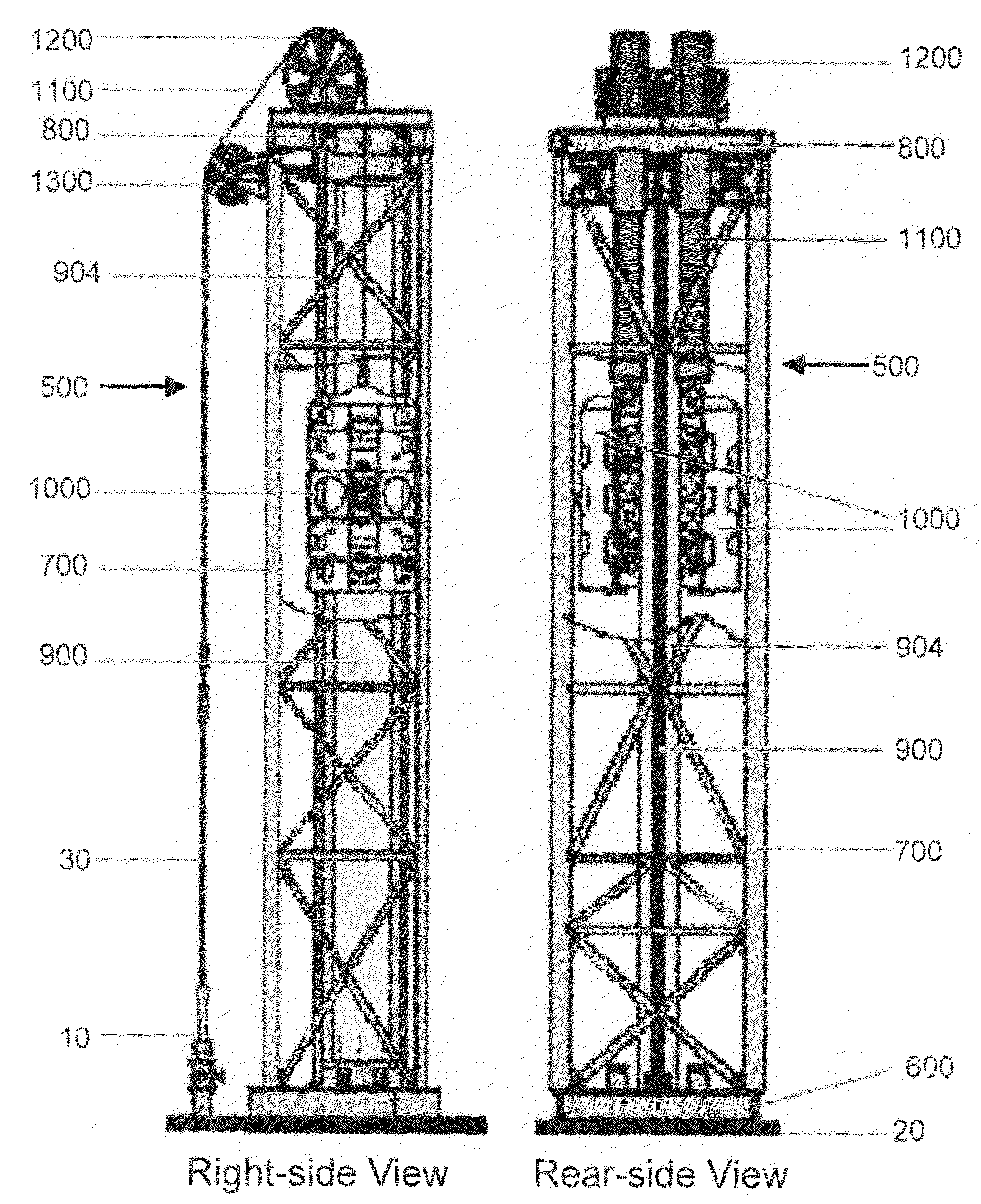

[0043]In accordance with one embodiment of the present invention, the linear motor actuated pumping unit 500 is placed adjacent to the wellhead 10 as illustrated in FIG. 5. The front-side of the pumping unit 500 faces the wellhead 10. FIG. 5 presents a right-side view and a rear-side view of the pumping unit 500. The base skid 600 of the pumping unit 500 is mounted on top of a concrete foundation 20. A vertical steel structure 700 is constructed on top of the base skid 600 to support the weight of the functional components in the pumping unit 500. An upper plate 800 is attached to the top of the vertical steel structure 700. A two-sided stator track 900 is housed in the interior of the vertical steel structure 700. The bottom end of the stator track 900 is attached to the base skid 600, while the top end is attached to the upper plate 800. The slider and counterweight in the present invention are combined to form a single slider / counterweight motor complex 1000, which surro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com