Drum for a production unit for a non-woven material, method for production of a non-woven material and non-woven material obtained thus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

DETAILED DESCRIPTION OF THE DRAWINGS

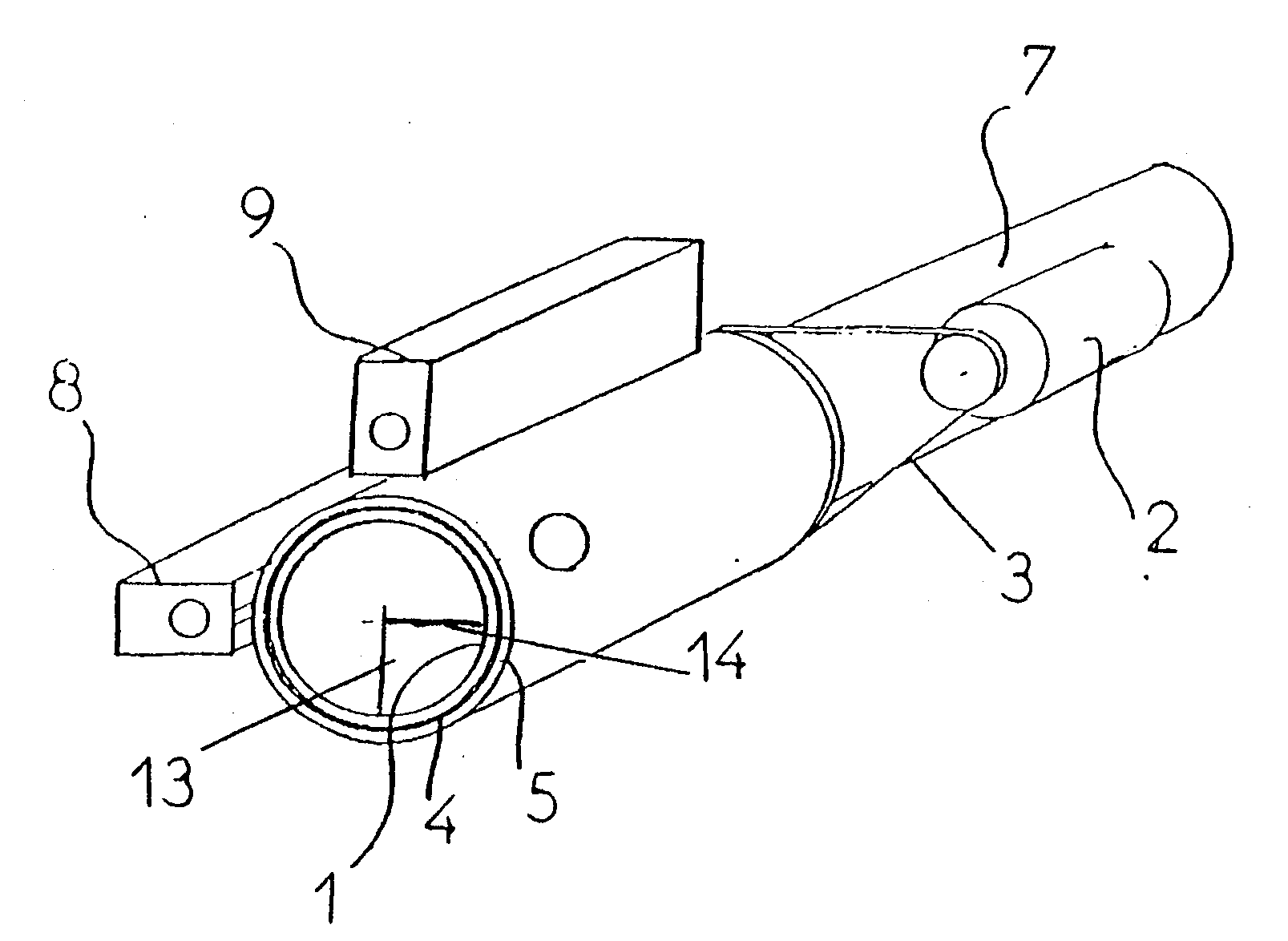

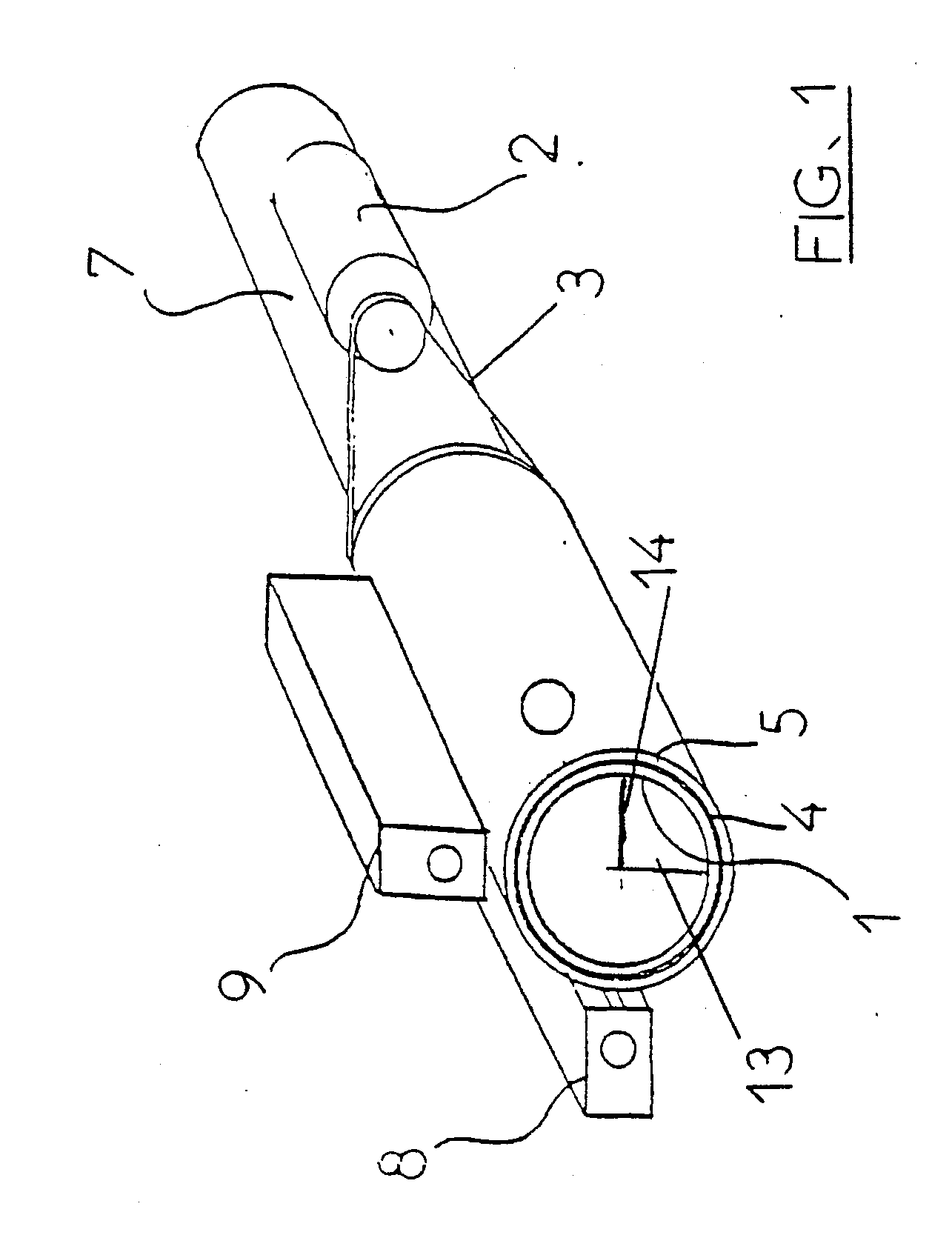

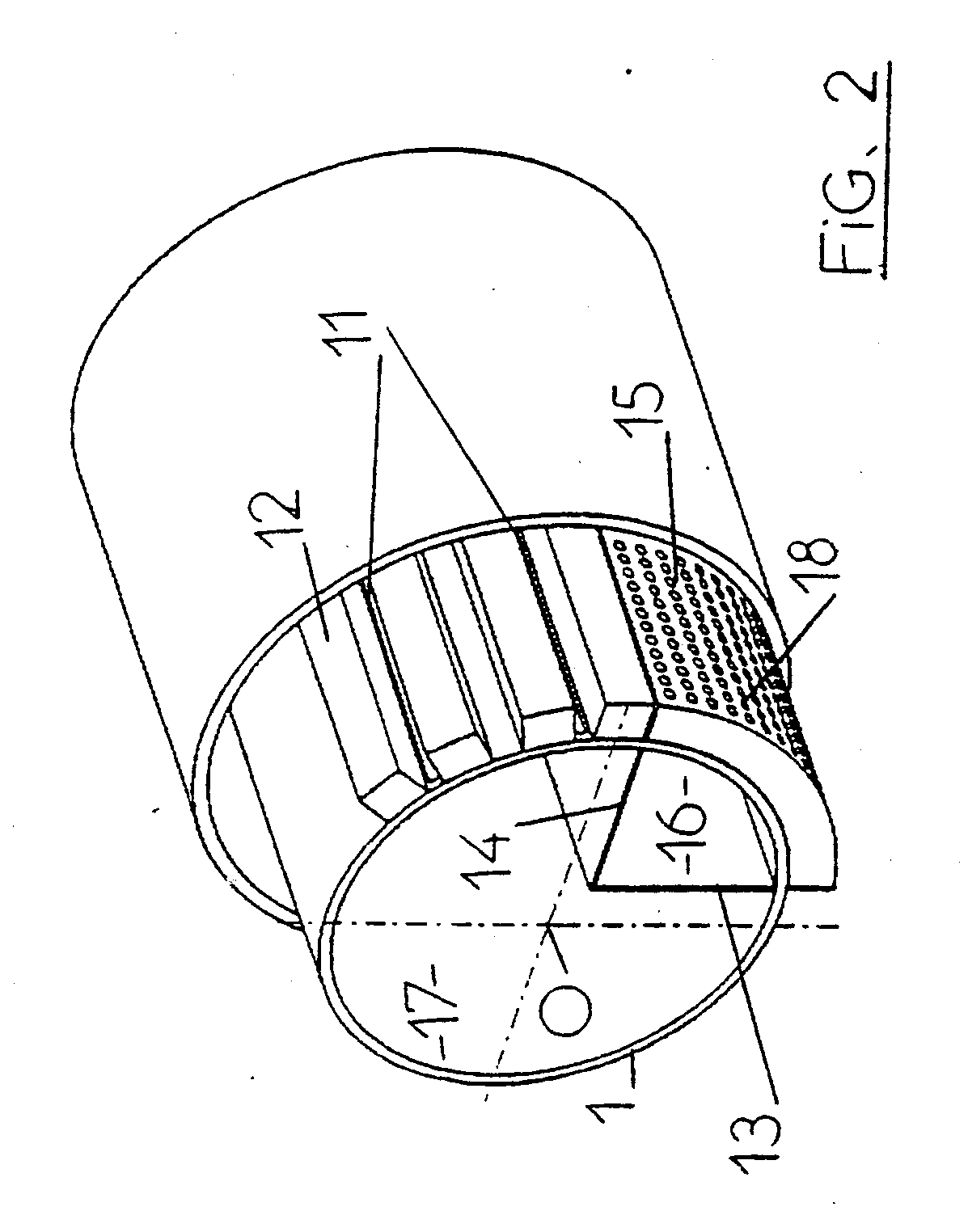

[0022] The drum represented schematically in FIG. 1 comprises an internal body 1 consisting of a fixed roll with a diameter of 400 mm and of a metal sheet forming the lateral surface. The lateral surface is perforated with perforations of a diameter of 8 mm in one portion which will delimit what will later be called the first compartment and the lateral surface is pierced with several slots particularly opposite the injectors in a portion which will delimit what will later be called the second compartment. The ratio (void fraction) of the sum of the areas of the perforations to the total lateral surface area is between 5% and 30% in the first compartment and between 2% and 15% in the second compartment. A perforated rotating roll 4 is slipped over the body 1 and is driven in rotation by a belt drive device 2. The roll 4 is holed. The ratio of the sum of the areas of the holes to the total lateral surface area of the roll 4 is between 30% and 90% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Speed | aaaaa | aaaaa |

| Dimension | aaaaa | aaaaa |

| Displacement | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com