Direct drive hose reel assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

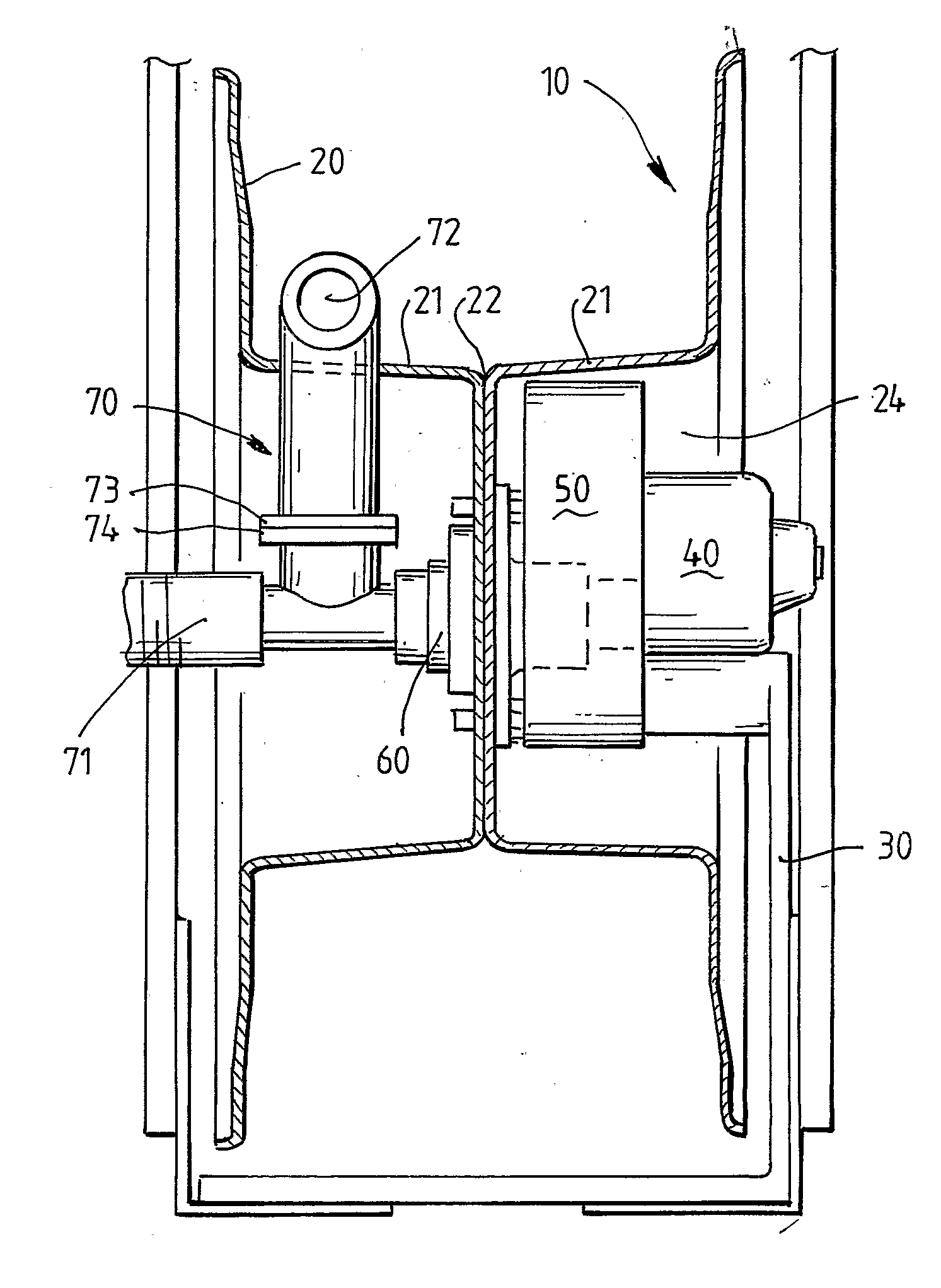

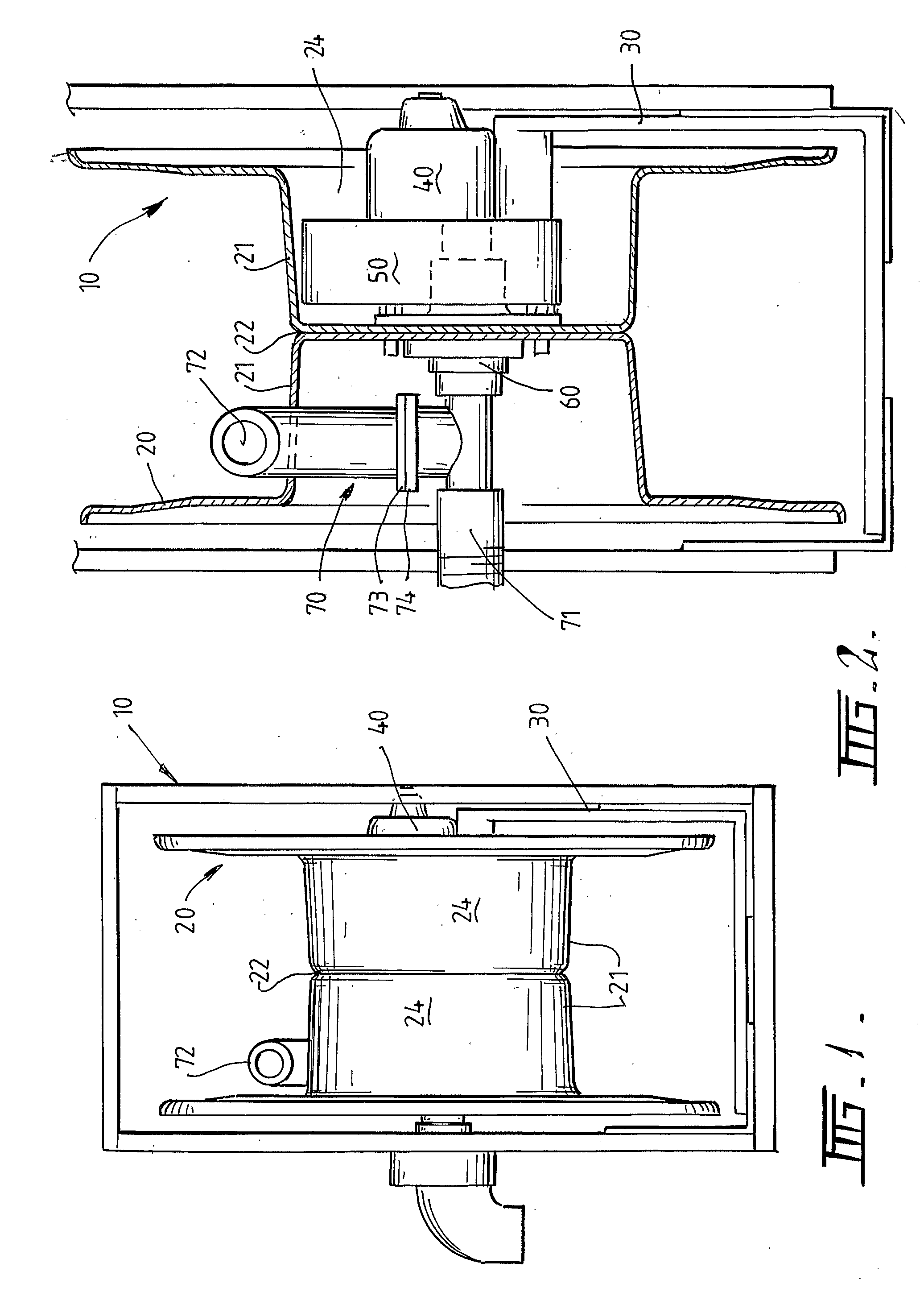

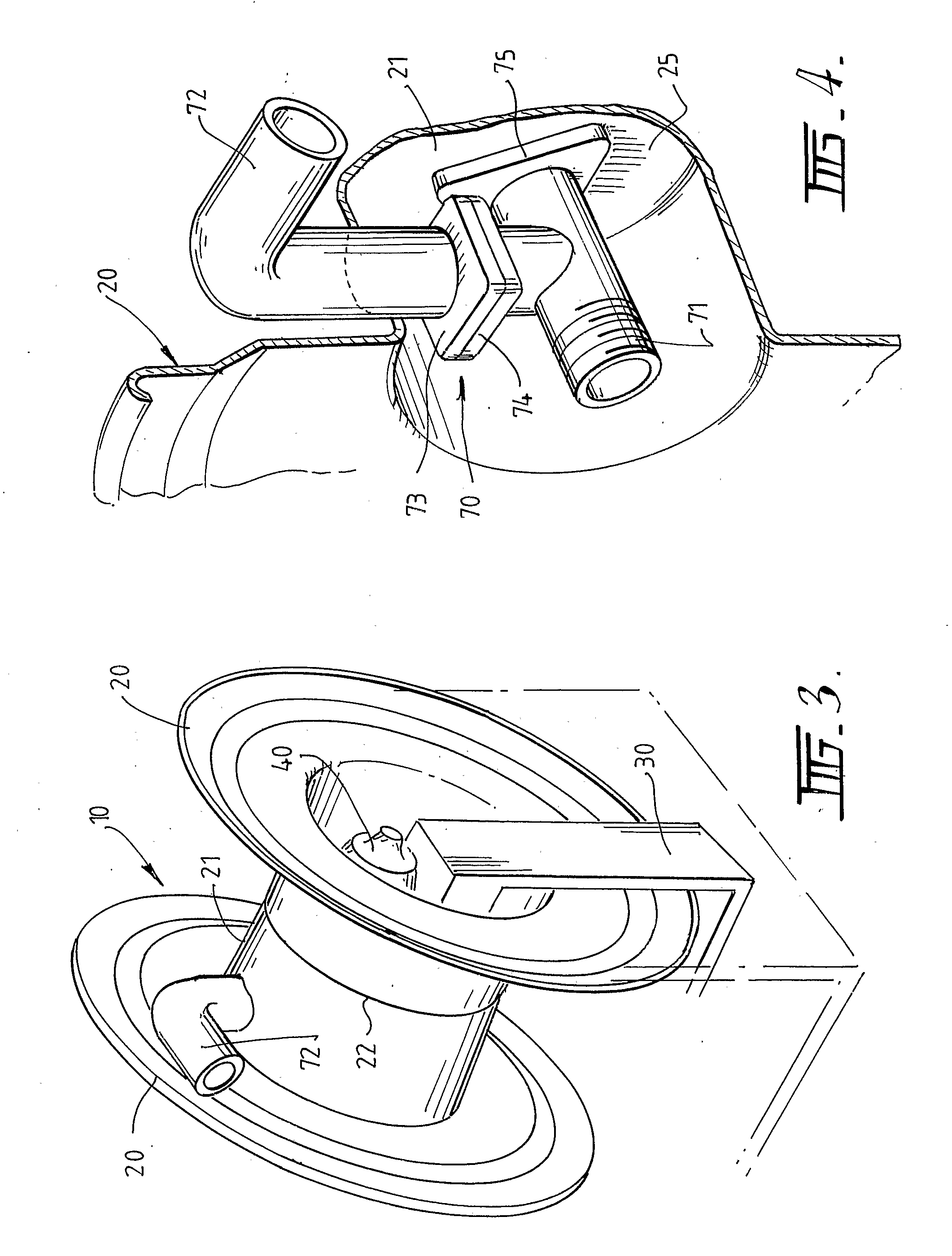

[0017] In one embodiment of the invention a hose reel assembly 10 as shown in FIG. 2 is provided in which the reel spool 20 is supported on a mounting frame 30 or support associated with a single automotive style stub axle, bearing and five stud hub assembly. By this means simplicity of servicing is provided and assembly and disassembly of the reel is accomplished in a similar manner to changing a vehicle wheel.

[0018] In addition the factory assembly of this reel assembly is time effective due to the use of the 5 stud hub construction. Many previous reels have used two bearing blocks on each side of the hub shaft that require general axial alignment and add to the width of the assembly. The design of the present invention eliminates this requirement.

[0019] Additionally other reels rely on the bearing assembly within the drive unit to support the spool whereas the hub loads in the reel system of the invention are taken up by the support and are not transmitted to the bearings of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com