Can bodies

a can body and canning technology, applied in the field of can bodies, can solve the problems of difficult separation of straight tapered can bodies, space saving in packing and nesting, etc., and achieve the effects of convenient separation, convenient further processing, and space saving during storag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

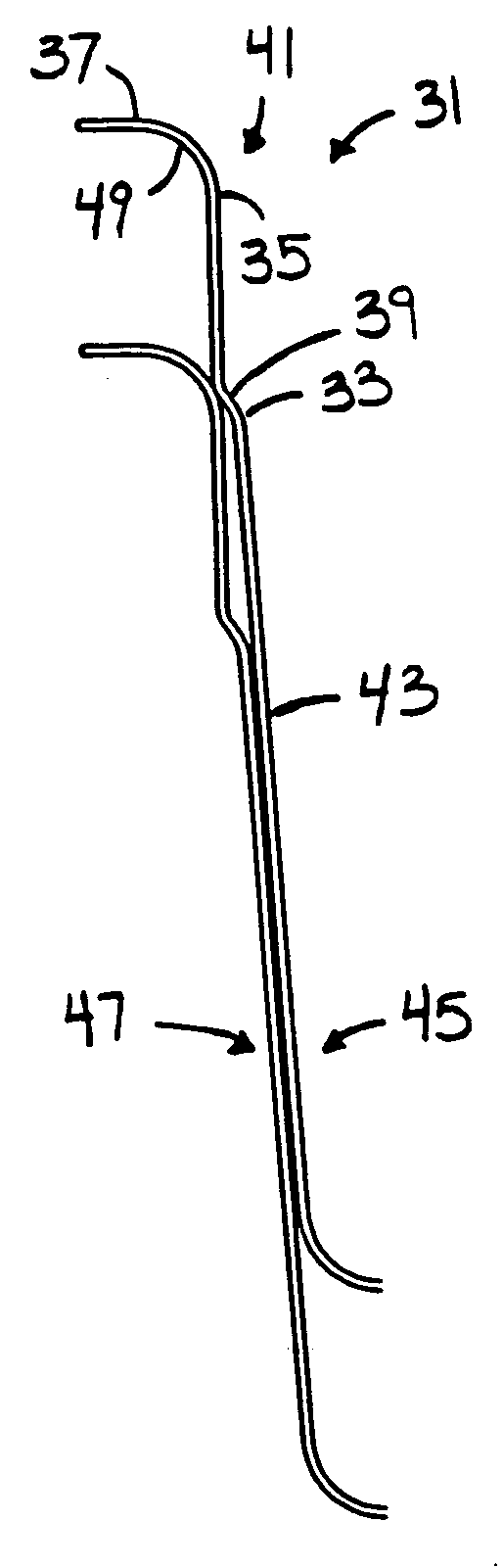

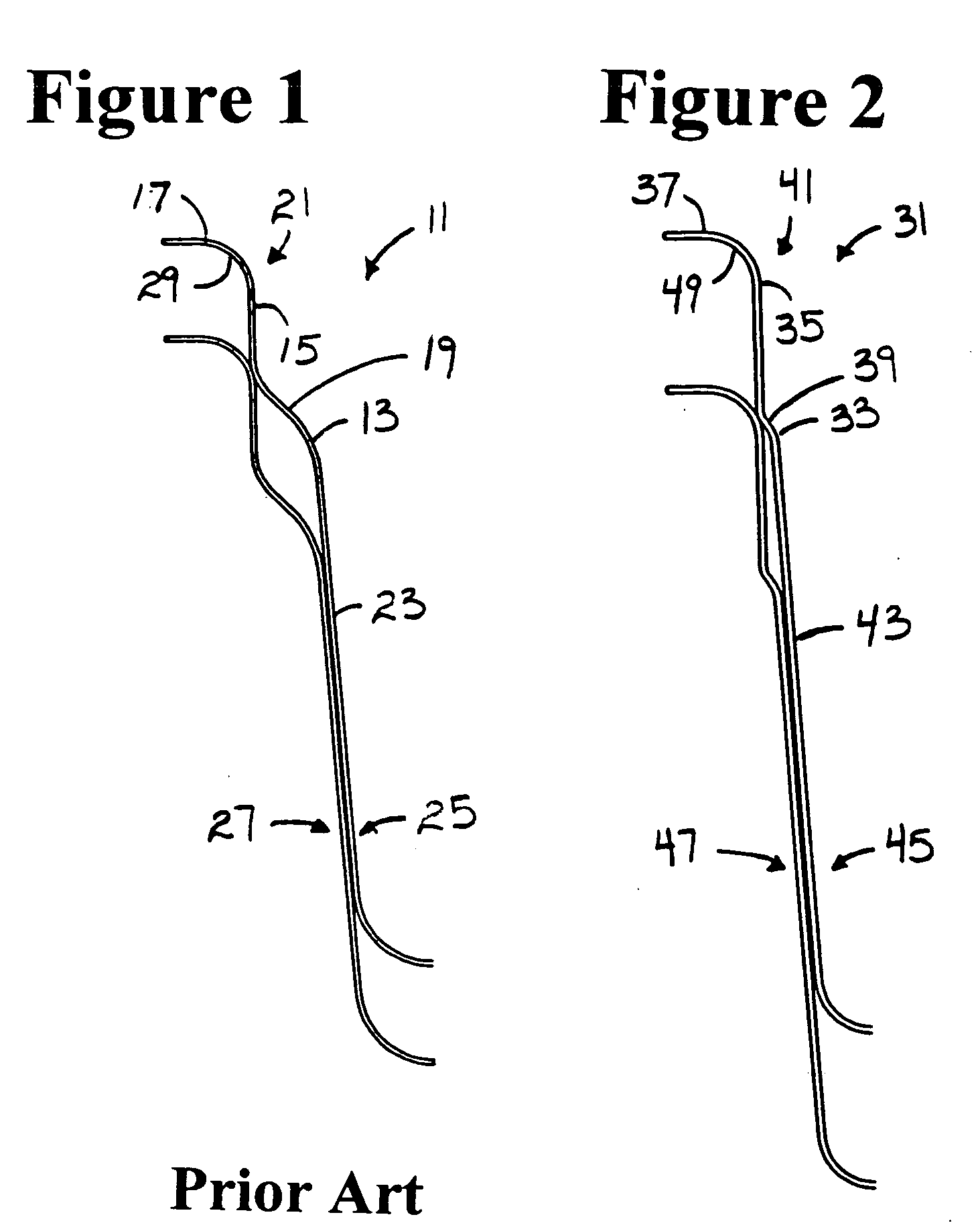

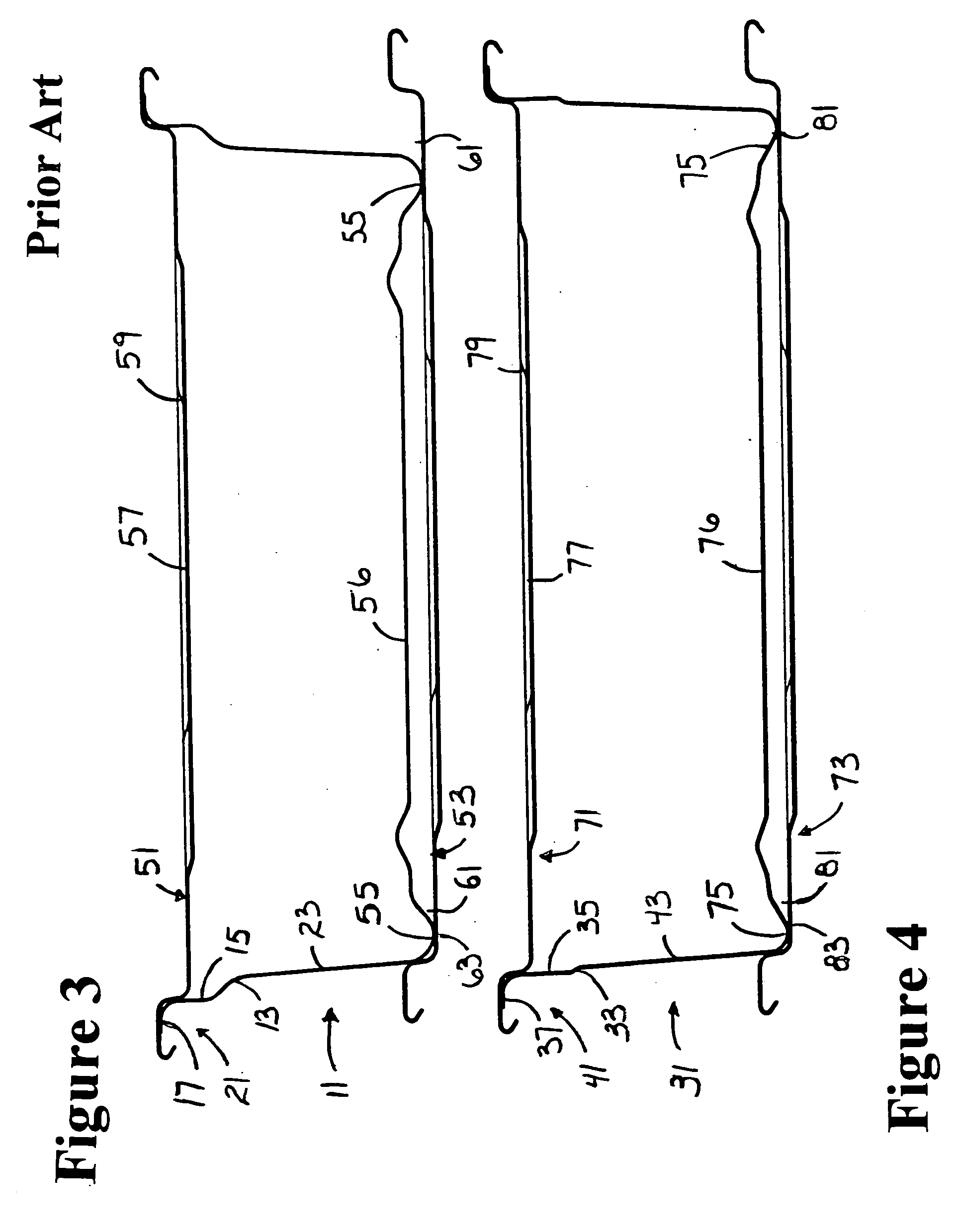

[0026] The present invention provides new can bodies that are stackable after manufacture, during shipment and before use. The new can bodies have slightly tapered sidewalls with small shoulders near open ends, which allow empty cans to stack together in a nested arrangement and to separate easily before filling. The stacking and nesting saves space during storage and transportation. The new structure of the can bodies incorporates small shoulders near the open ends of the can bodies to control depth of insertion of adjacent stacked can bodies and prevent the can bodies from sticking together when nested in a stack and when being separated prior to filling. Thus, cans are separated easily for further processing. The new, small shoulder structure permits a shallower and / or steeper sidewall, thereby maximizing the size of the bottom of the can body and the volume content of the can.

[0027] The stacking of can bodies requires that some space be left between the can bodies. Straight tap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com