Machine laminated basketball

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

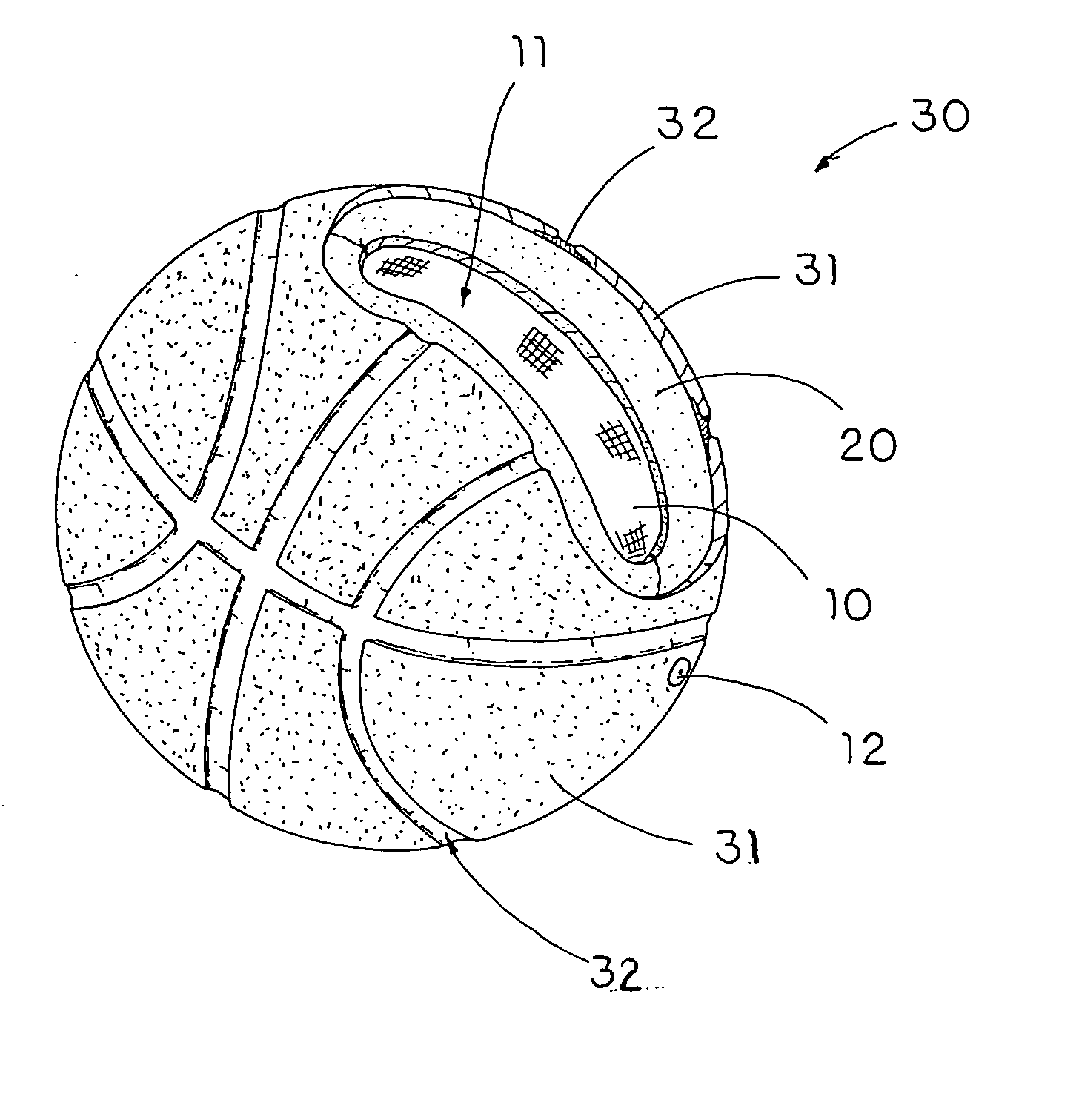

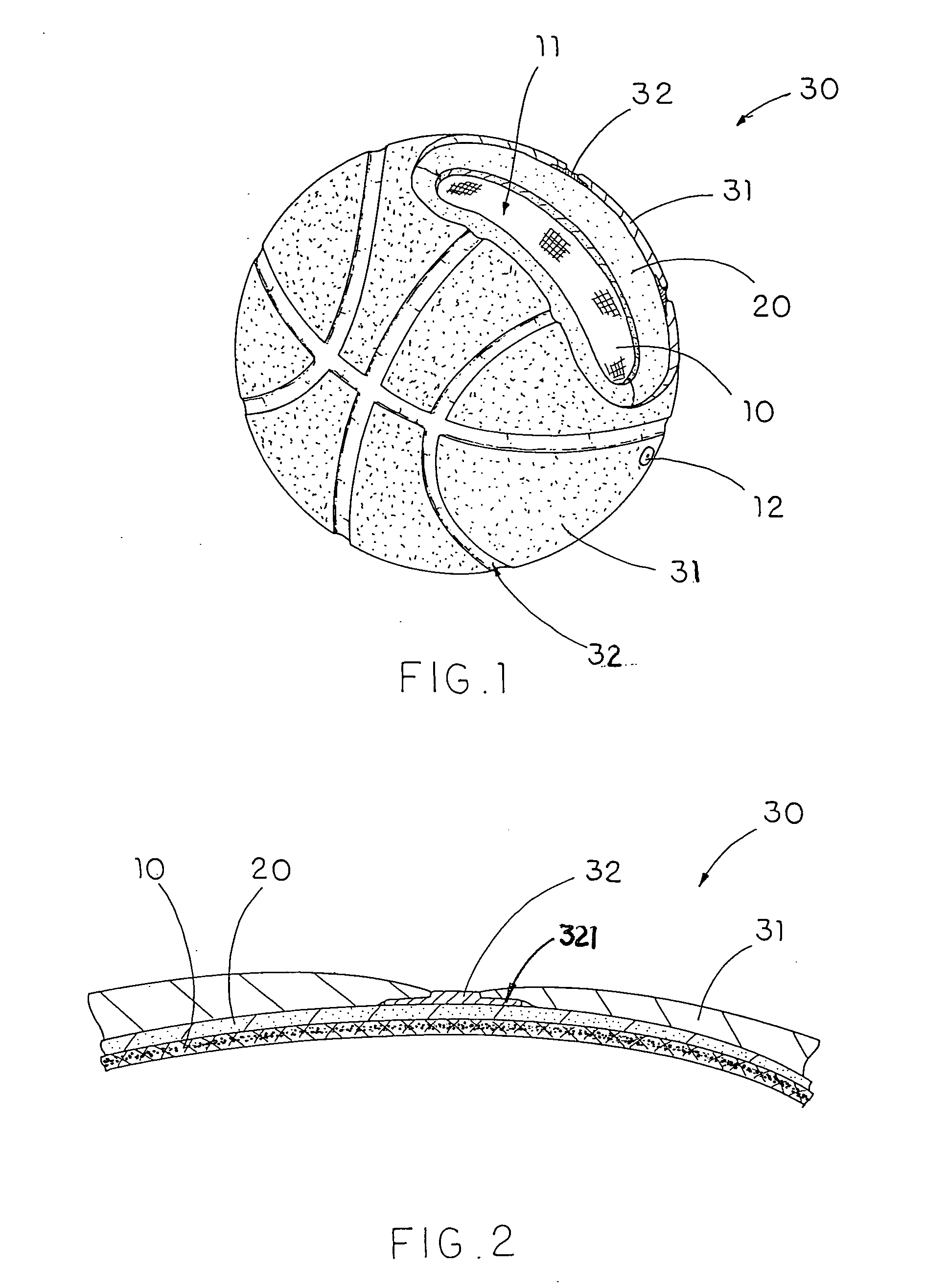

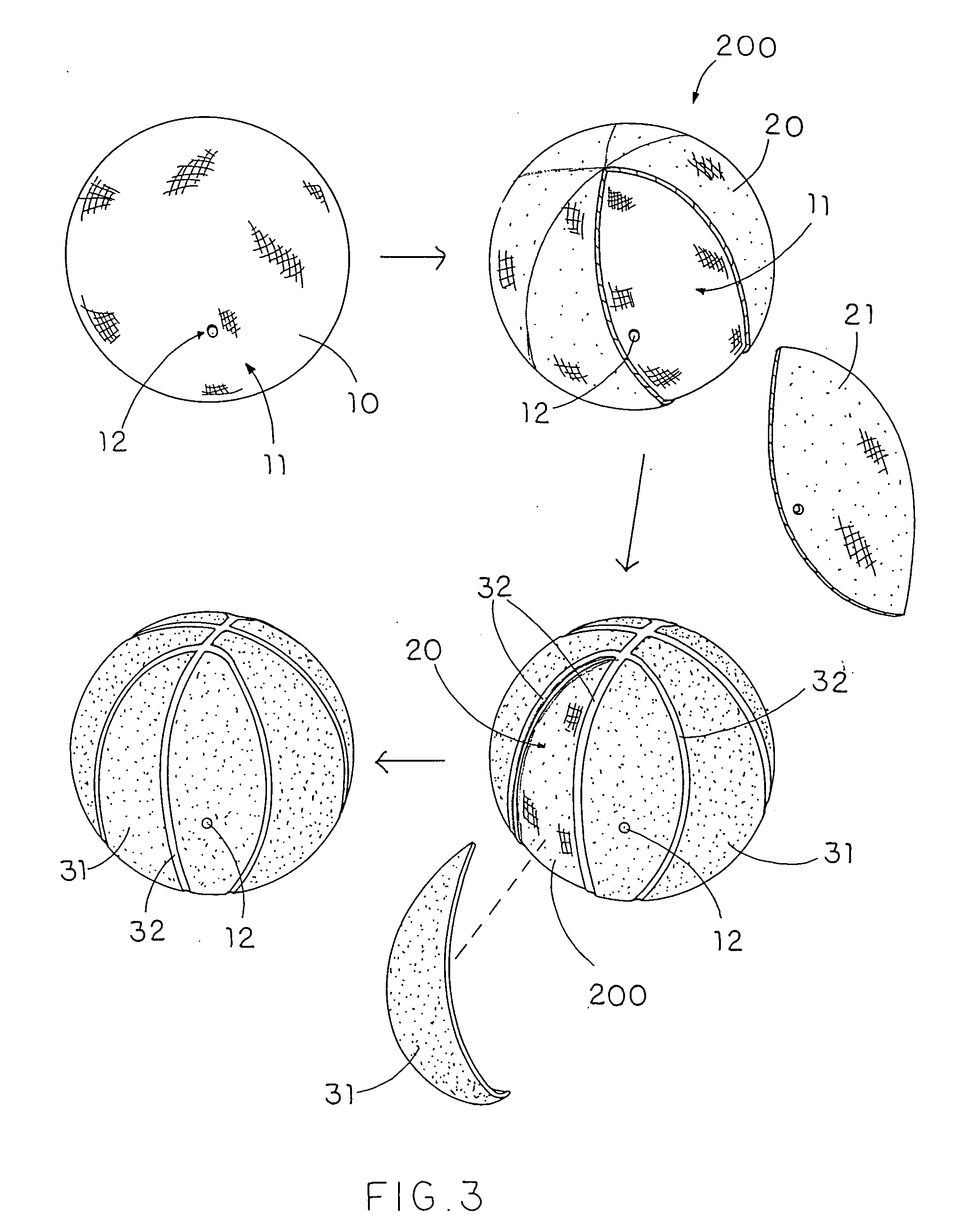

[0044] Referring to FIG. 1 to FIG. 2 of the drawings, a basketball according to a preferred embodiment of the present invention is illustrated, in which the basketball comprises a channel-less carcass 10, a cushion layer 20 and a skin cover 30.

[0045] The inflatable channel-less carcass 10 has a smooth spherical outer surface 11 and a valve stem 12 formed on the channel-less carcass 10, wherein the channel-less carcass 10 is inflated via the valve stem 12 to support the skin cover 30 to form the basketball. The channel-less carcass 10 can be made by the following steps:

[0046] (i) winding an inflatable rubber ball bladder with reinforcing thread to form a winding thread layer surrounding said rubber ball bladder so as to form an inner carcass;

[0047] (b) covering the inner carcass with an outer rubber layer; and

[0048] (c) heat molding and vulcanizing the inner carcass with the outer rubber layer in a vulcanizing mold to integrally fusion the inner carcass and the outer rubber layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com