Displacement filter apparatus and method

a filter and displacement technology, applied in the direction of filtration separation, sedimentation settling tanks, separation processes, etc., can solve the problems of large and costly support frames and hydraulic systems, ineffective filtering methods, and inability to pass through liquid, etc., to reduce the time necessary, simplify and cost-effective, and the effect of less costly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

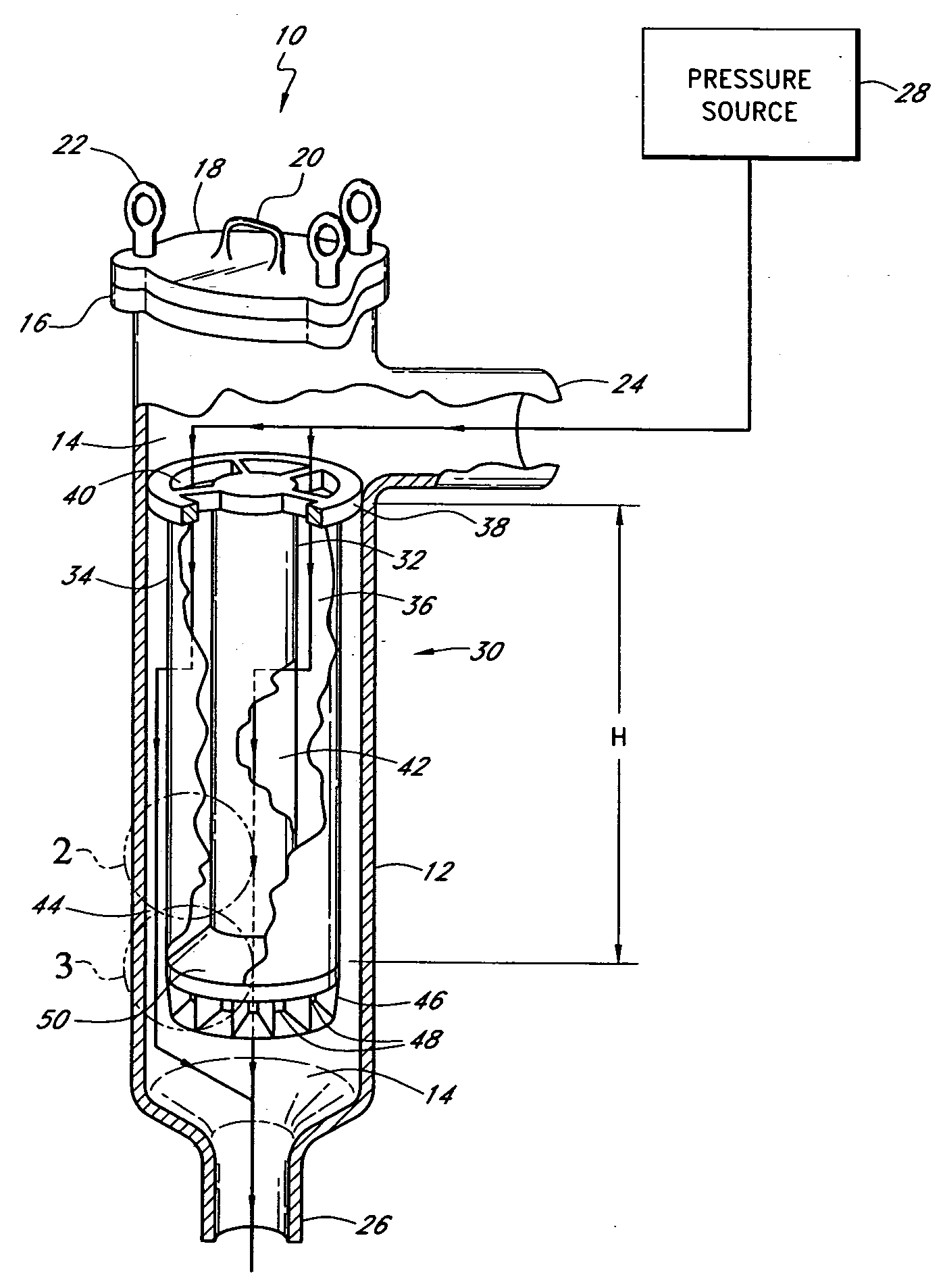

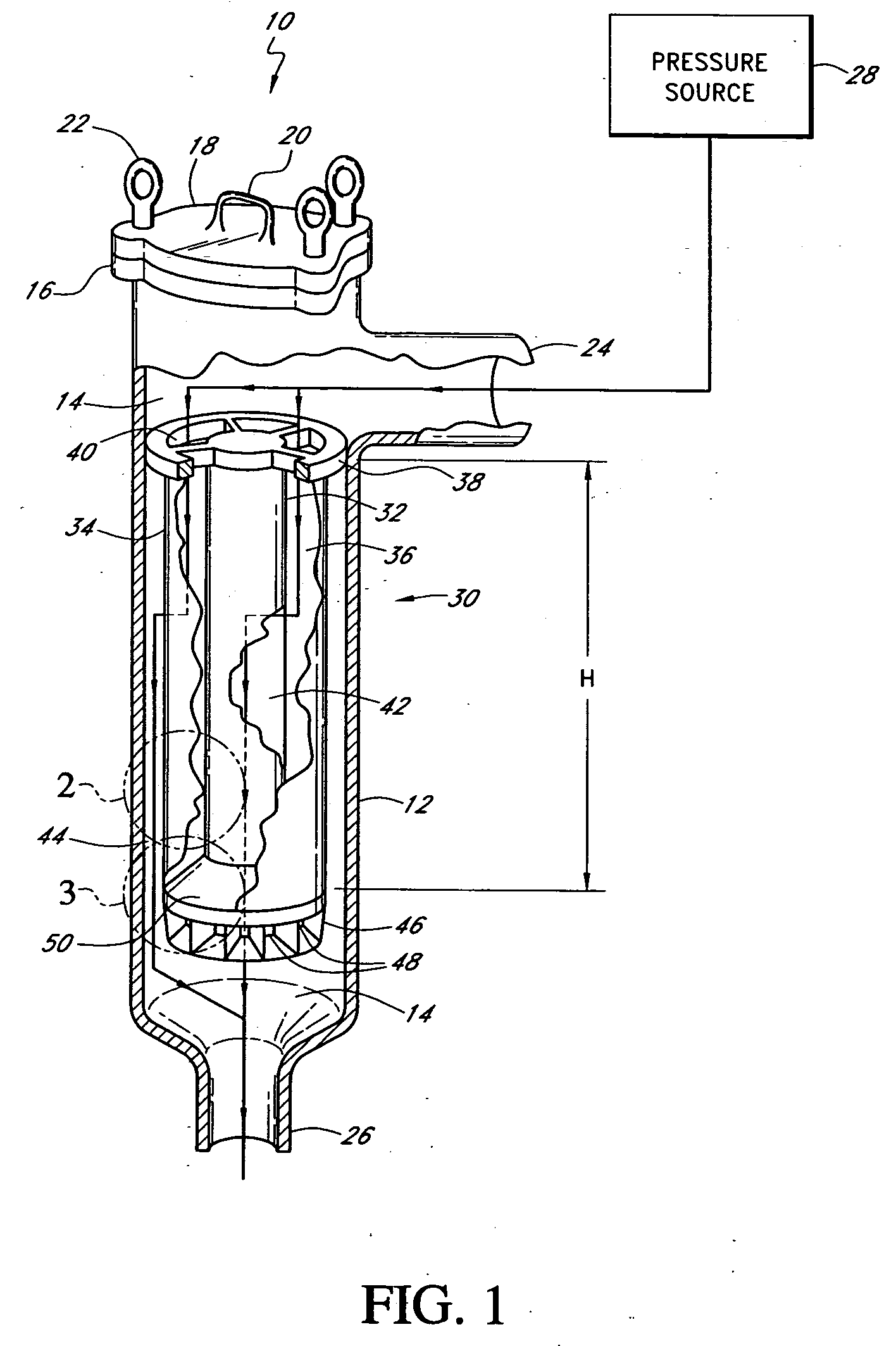

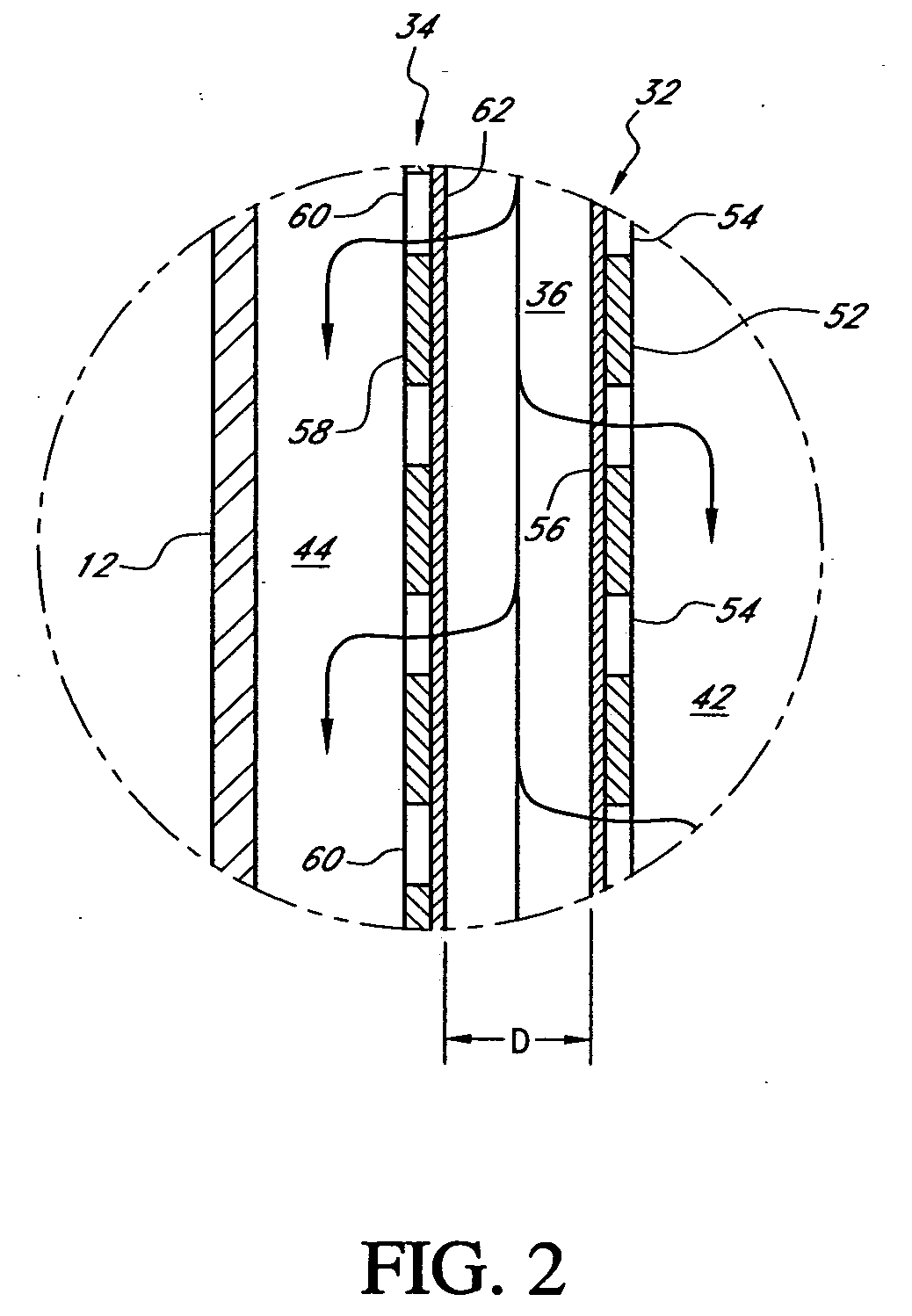

[0045]FIGS. 1-3 illustrate a preferred embodiment of a filter apparatus 10, generally referred to as a “filter” herein. The filter 10 includes a substantially tube-shaped vessel 12 that defines an enclosed space, generally referred to by the reference numeral 14. The upper, open end of the vessel 12 terminates in a flange 16, which extends generally perpendicular to the wall of the vessel 12. A closure, or lid 18, preferably rests on the flange 16 to close the upper end of the vessel 12. The lid 18 may include a handle 20 to allow the lid 18 to be easily removed. Desirably, the lid 18 is capable of being secured to the vessel 12 so as to form a fluid tight seal. In the illustrated embodiment, a number of threaded fasteners, such as eyebolts 22, secure the lid 18 to the flange portion 16 of the vessel 12. However, other suitable means of attachment may also be used, such as other mechanical or hydraulic means. In addition, other suitable methods of closing the vessel 12 may be utiliz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| particulate size | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com