Hose reel

a hose and reel technology, applied in the direction of transportation and packaging, thin material processing, filament handling, etc., can solve the problems of high inconvenient, high labor intensity, and messy coiling of hose around the winding drum, and achieve the effect of simple structure, convenience and ease of us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

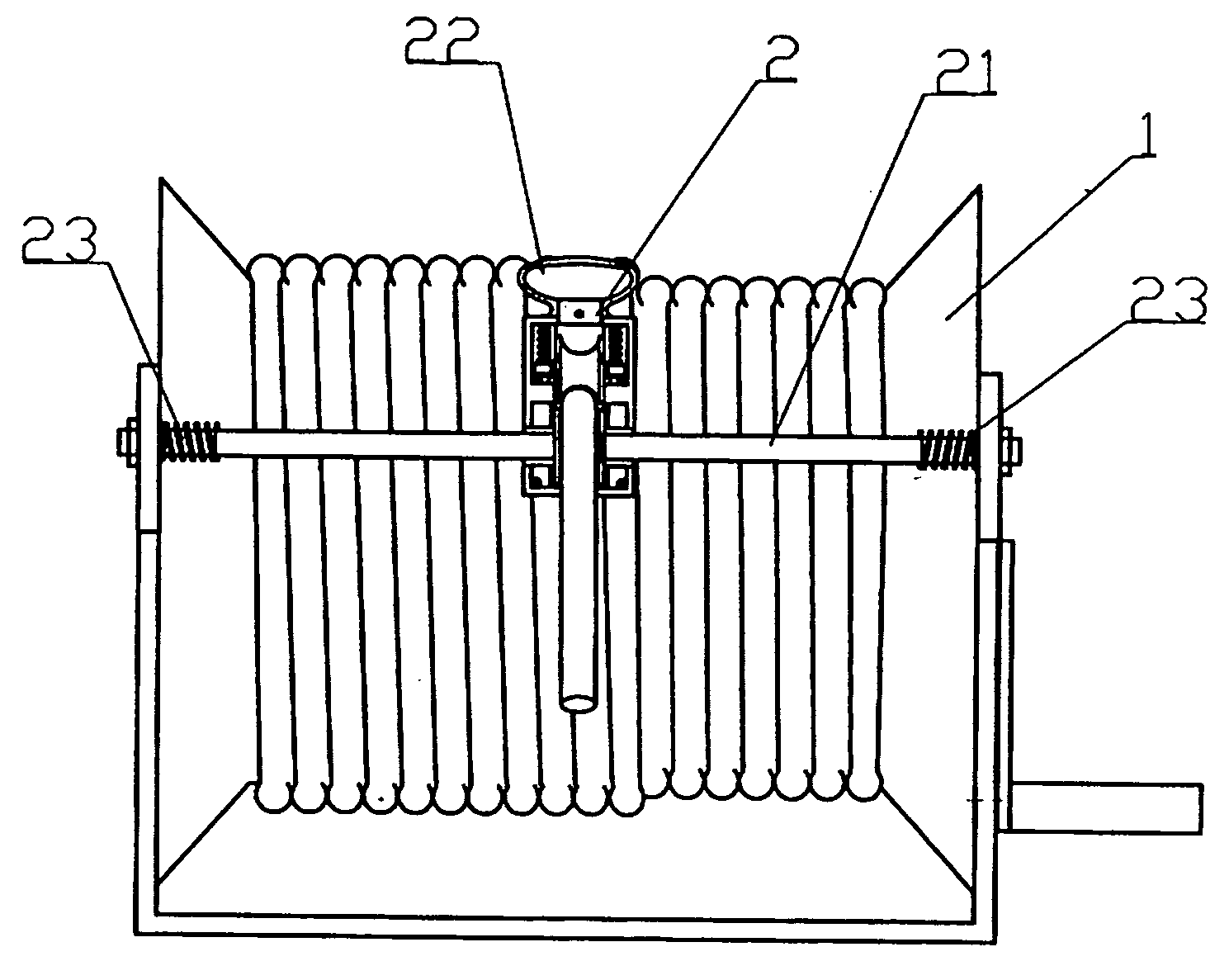

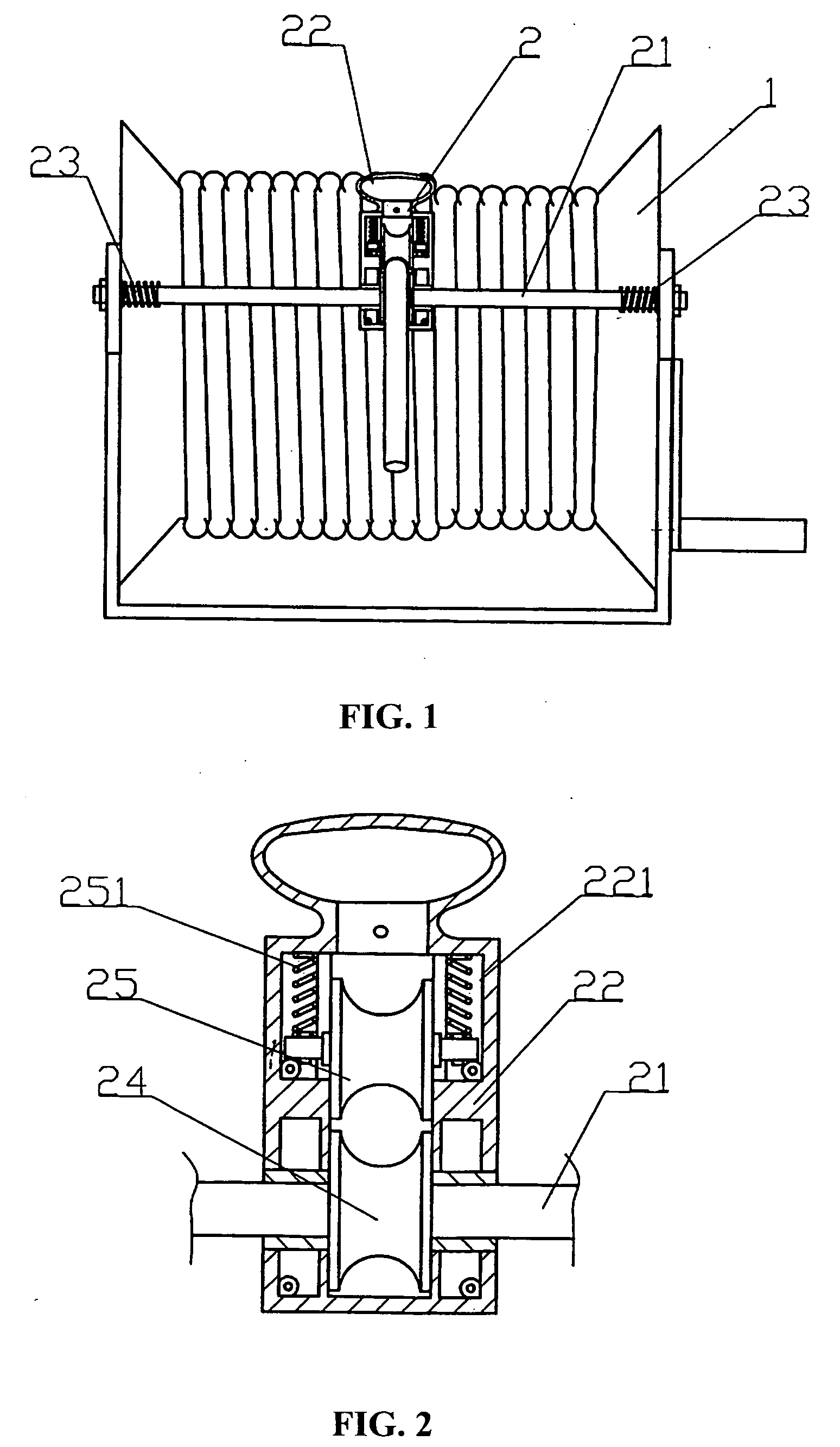

[0024] With reference to FIG. 1, a hose reel includes a winding drum 1 and a support. The winding drum 1 is mounted on the support. A hose is coiled around the winding drum 1. The hose reel further comprises a positioning assembly 2 that includes a guide rod 21, a positioning unit 22, and two springs 23. The positioning unit 22 is slidably mounted on the guide rod 21. The two ends of the guide rod 21 rest on the support. The two springs 23 fit over the guide rod 21 and are separately disposed on two sides of the positioning unit 22. The positioning unit 22 has a hose hole. The hose passes out through this hose hole. When the winding drum 1 is rotated to coil the hose, the hose that wraps around the winding drum 1 exerts a lateral force on the hose hole in the positioning unit 22, causing the hose that is being coiled around the winding drum 1 to be coiled sequentially. In addition, the positioning unit 22 guides the hose along the guide rod 21. When the hose is coiled to the very en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com