Marking tape measure

a technology of measuring tape and marking board, which is applied in the direction of measuring tape, measuring device, instruments, etc., can solve the problem of time-consuming task of marking board and panel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

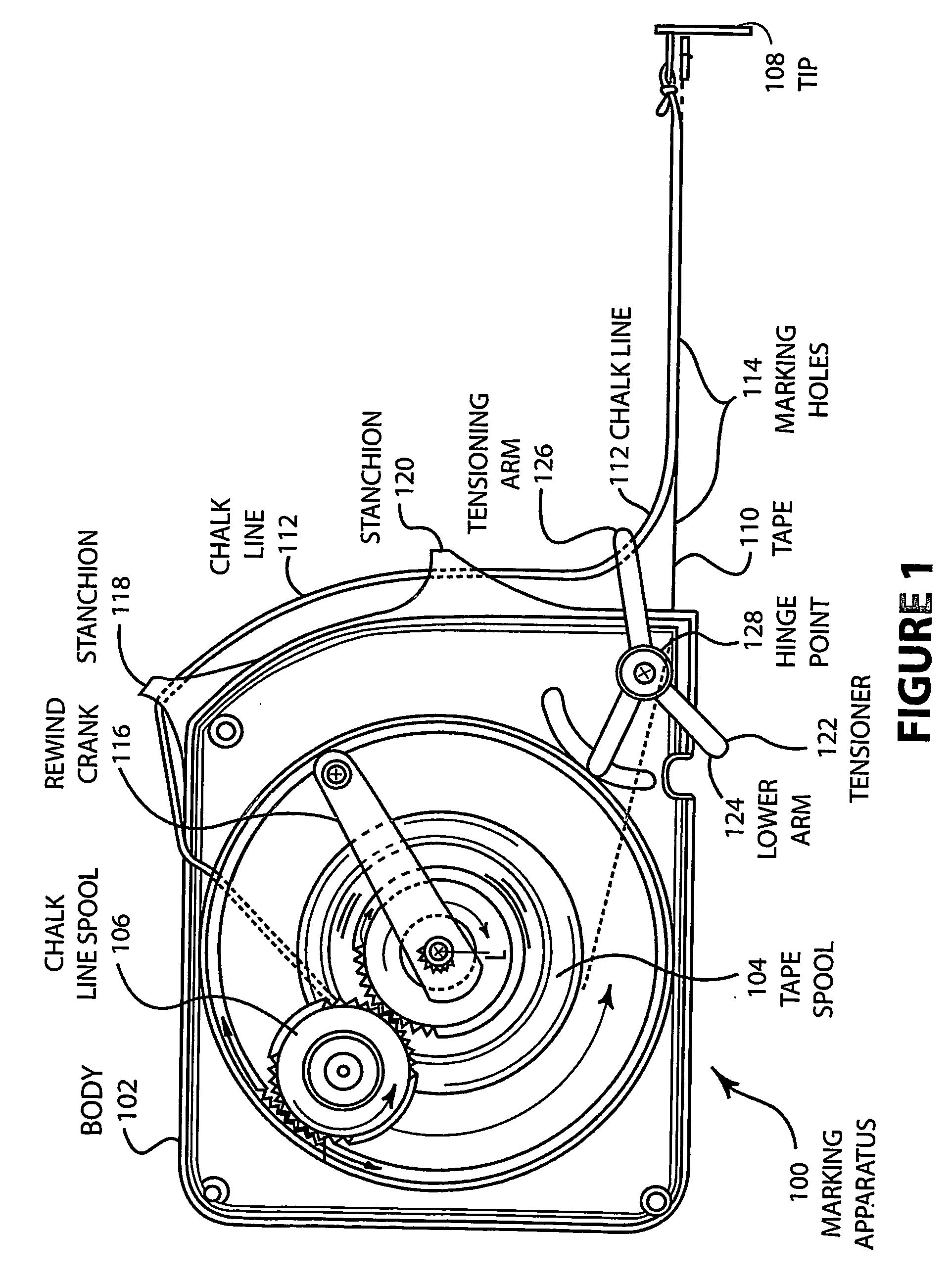

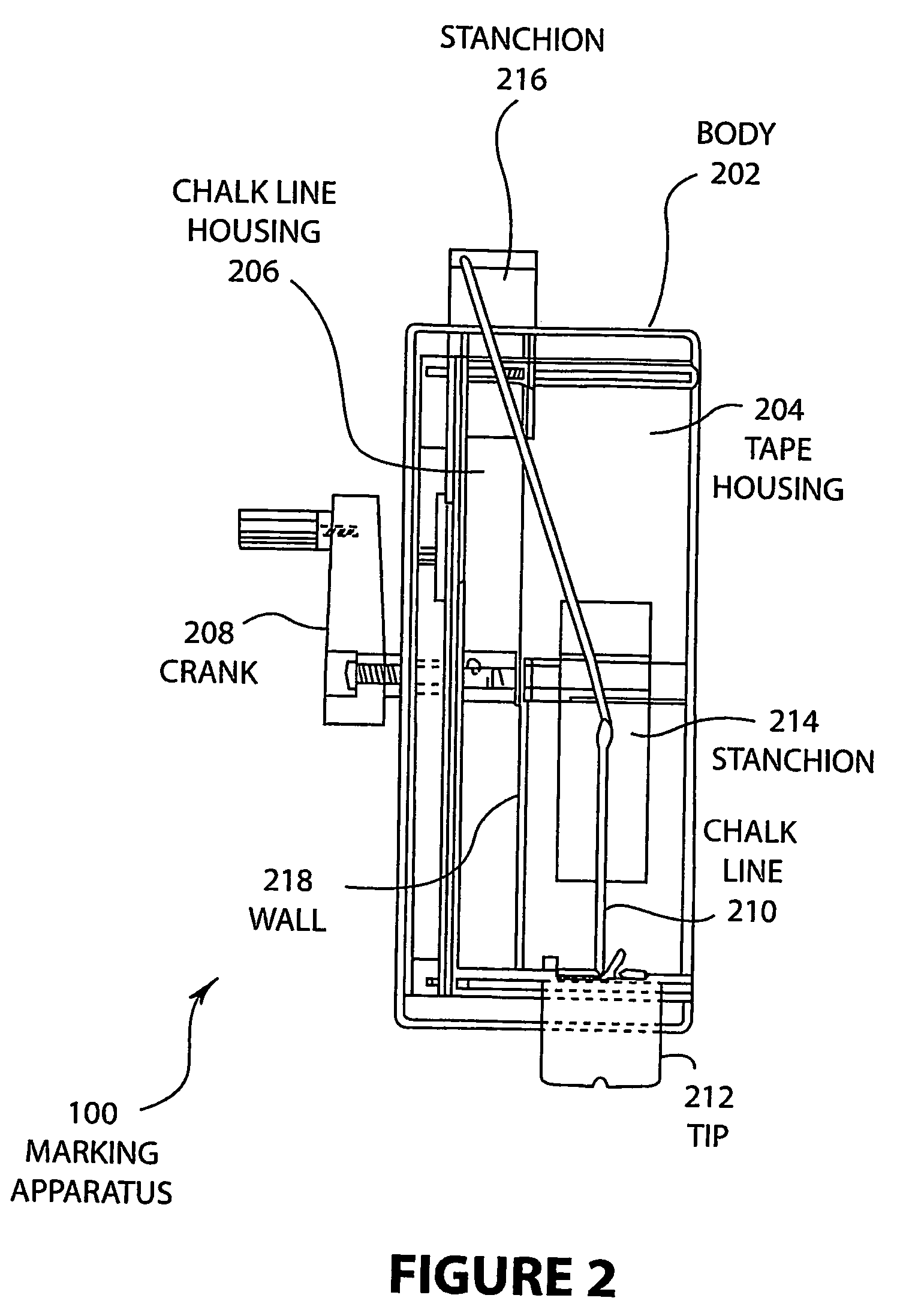

embodiment 100

[0021]FIG. 1 illustrates a cut away side view of an embodiment 100 of a marking apparatus. The body 102 contains a tape spool 104 and a chalk line spool 106. As the free end tip 108 is pulled away from the body 102, the tape 110 and chalk line 112 are extended with the chalk line 112 being located over or spanning the tape 110. The tape 110 has a series of marking holes 114 at predetermined intervals. The tape 110 and chalk line 112 can be simultaneously retracted into the body 102 by the rewind crank 116. The chalk line 112 travels through holes in stanchions 118 and 120 and tensioner 112.

[0022] In operation, one places the tip 108 of the device over the edge of a surface to be marked, then extends the tape 110 and chalk line 112 simultaneously along the length to be marked. When the tape in the marking apparatus 100 is extended over the length to be marked, the body 102 may be placed on top of the surface such that the lower arm 124 of the tensioner 112 is pressed against the surf...

embodiment 300

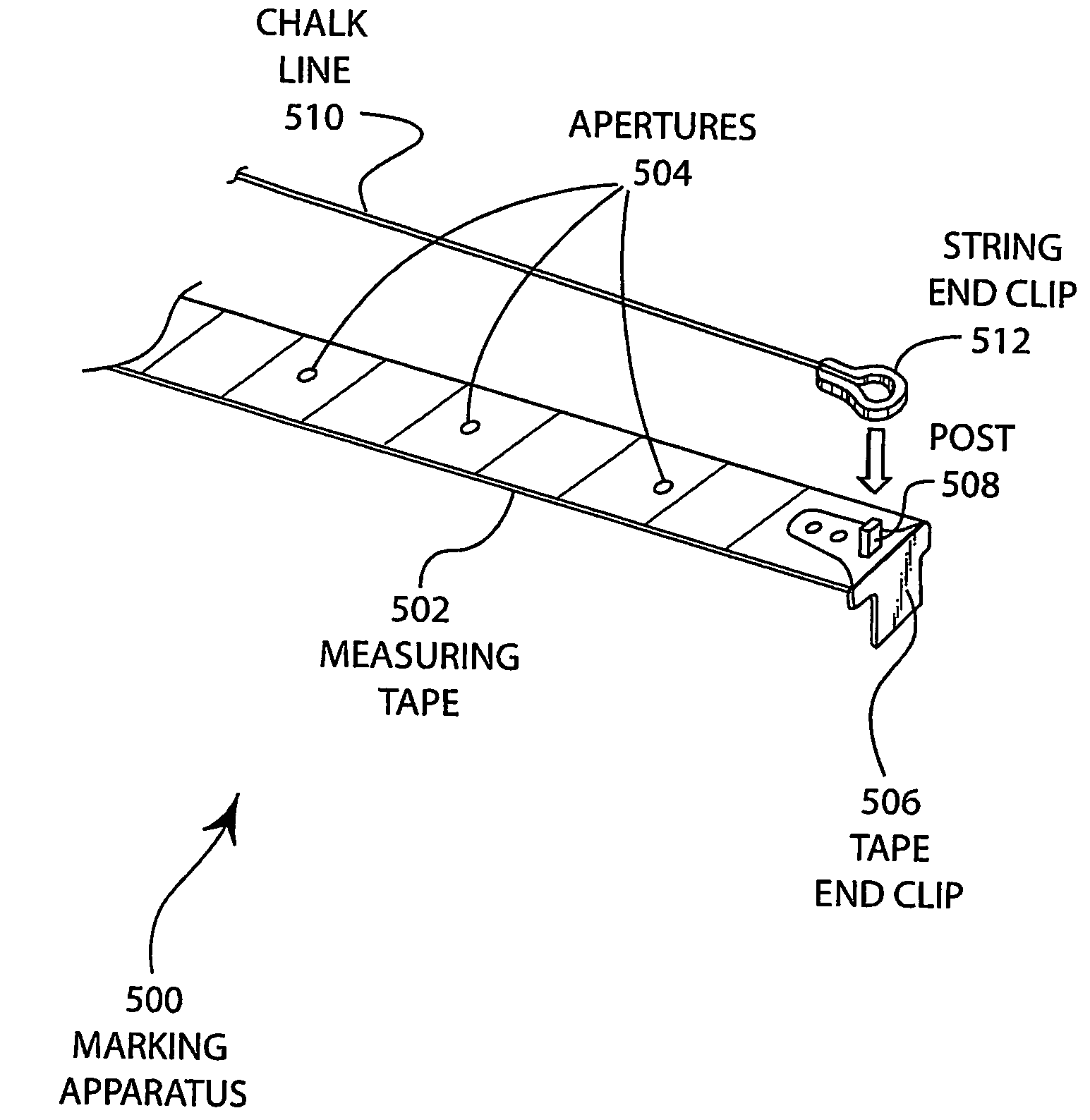

[0031]FIG. 3 illustrates a perspective view of an embodiment 300 of the present invention of a marking apparatus. The body 302 contains a tape spool 304 and a string spool 306. A tape locking lever 308 allows the tape to be locked in a particular position. A chalk filling door 310 may be opened to receive powdered chalk that can be carried on the string 314. The free end of the tape 312 may be hooked over the edge of a piece of wood or other article to be measured or marked. The string end clip 316 may be engaged on the post 317 when the device is used as a marking instrument.

[0032] The embodiment 300 may be used as a separate tape measure and string line. For example, to use the embodiment 300 as a tape measure, the string end clip 316 may be disengaged from the tape end clip 312 and stored in the string end clip holder 318. The tape may be extended from the tape spool 304 by pulling on the tape end clip 312. The tape may be an elongated sheet of metal or plastic and may have gradu...

embodiment 400

[0033]FIG. 4 illustrates a perspective view of an embodiment 400 of the present invention of a marking apparatus. The body 402 contains a tape spool 404 and a string spool 406. A tape locking lever 408 may lock the tape in a particular position. A chalk filling door 410 may be opened to receive powdered chalk or other marking medium that can be carried on the string 414. The tape end clip 412 has a post 417 that may receive the string end clip 416.

[0034] The embodiment 400 contains a string retract crank 418 that may engage the string spool 406 to retract the string 414 into the body 402. In some embodiments, the crank 418 may engage the string spool directly or may engage the spool by means of gears.

[0035] In some embodiments, the tape may be retracted by a spring mechanism. In some embodiments, the string and the tape may be retracted simultaneously and collectively by a gear mechanism between the tape spool and the string spool. In other embodiments, the tape and the spring may ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com