Carrier rack on air-vent

a carrier rack and air vent technology, applied in the direction of machine supports, furniture parts, bracket accessories, etc., can solve the problems of affecting the operation and appearance of the car, difficult adjustment, and restricting the application of the car

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

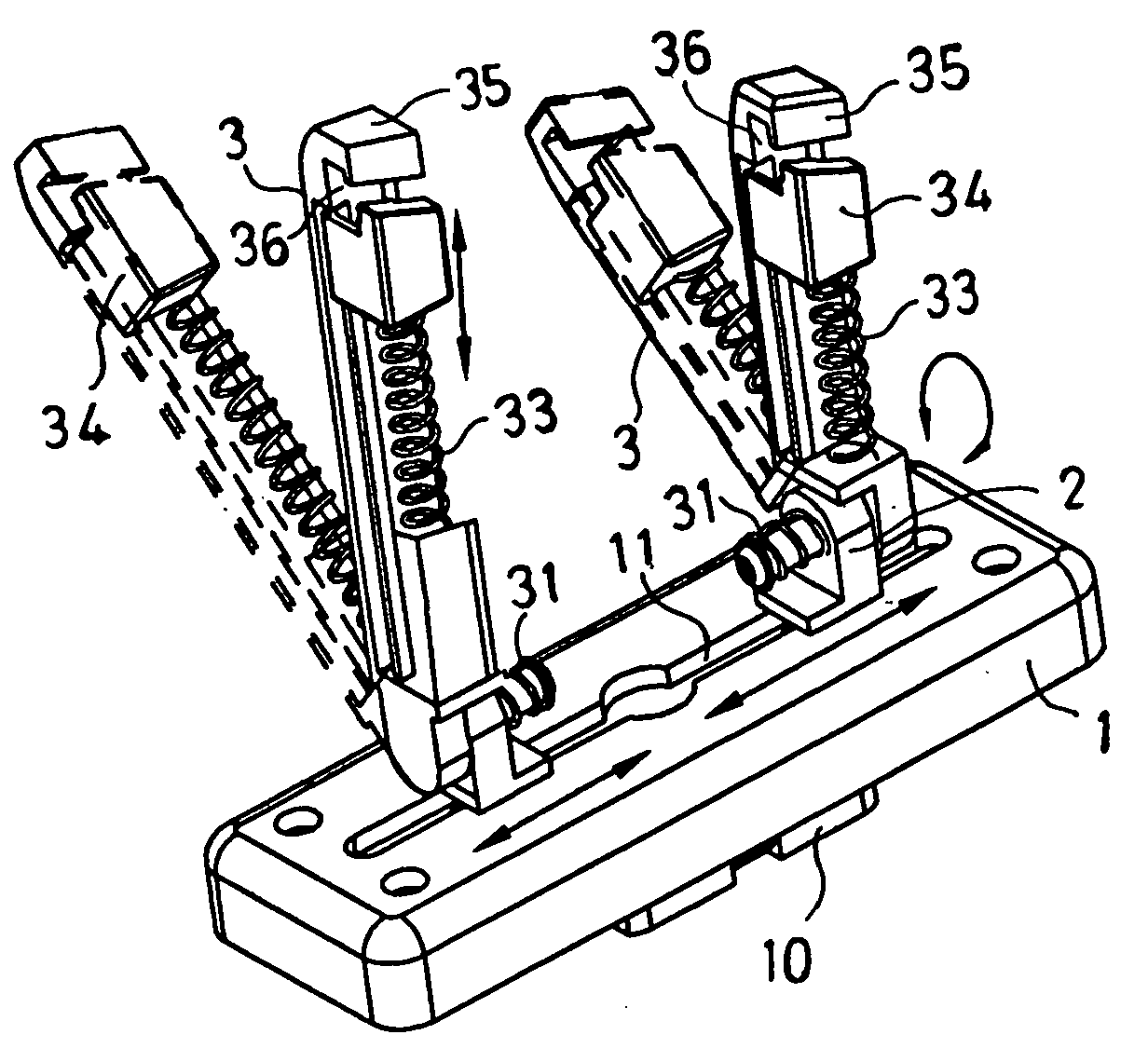

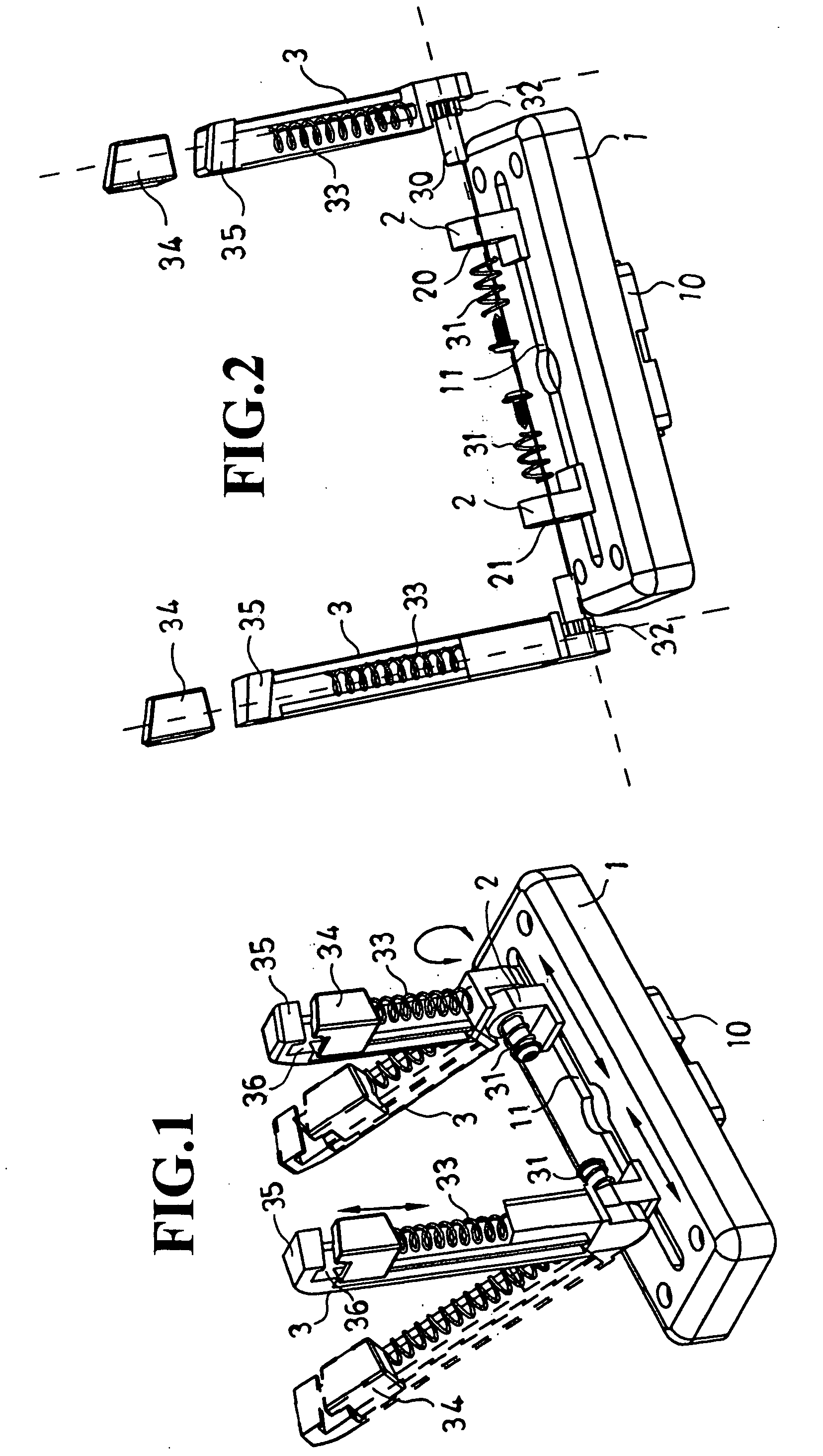

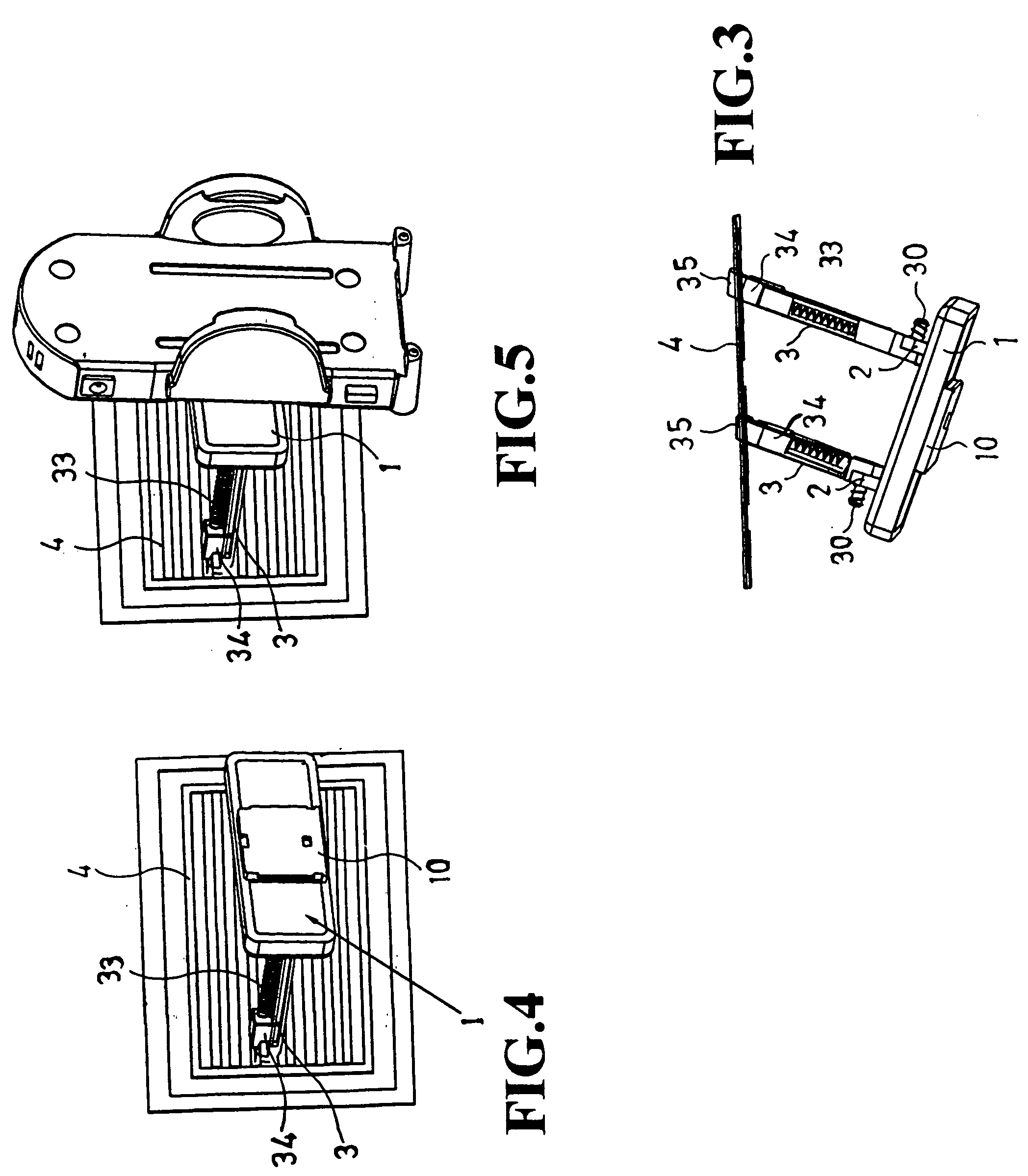

[0013] As shown in enclosed drawings, the present invention comprises a carrier 1, a pair of sliding blocks 2 and a pair of arm levers 3; wherein the carrier 1 comprises a clasping bracket 10 on one side and a sliding groove 11 on the rear side; the sliding groove 11 can engage the sliding blocks 2 that slide left and right; each sliding block 2 has a round through hole 20 on the end; each of the round through hole 20 has a gullets 21 at the proper position around the edge; a arm lever 3 connects to the round through hole 20 with a bolt support 30 and a spring 31; a sprocket 32 locates on the arm lever 3 corresponding to and passing through the gullet 21; the arm lever 3 further comprises a resilient lockout 34 that moves back and forth under the pressure of a compression spring 33; the lockout 34 cooperates with a hook 35 to form a clasping channel 36; the axis of the round through hole 20 is unparallel to the carrier 1 such that the carrier 1 can form an offset angle with the air-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com