Dark-banded vial for use with level

a dark banded, vial technology, applied in the field of vials, can solve the problems of putting constraints on the time, difficult to see on a heavily clouded day, at dusk, in poorly lit spaces, prior art attempts have failed to provide a simple and inexpensive, yet successful method of overcoming bubble-locating problems, etc., to achieve the effect of improving the visibility of the bubble and facilitating the locating of the bubbl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

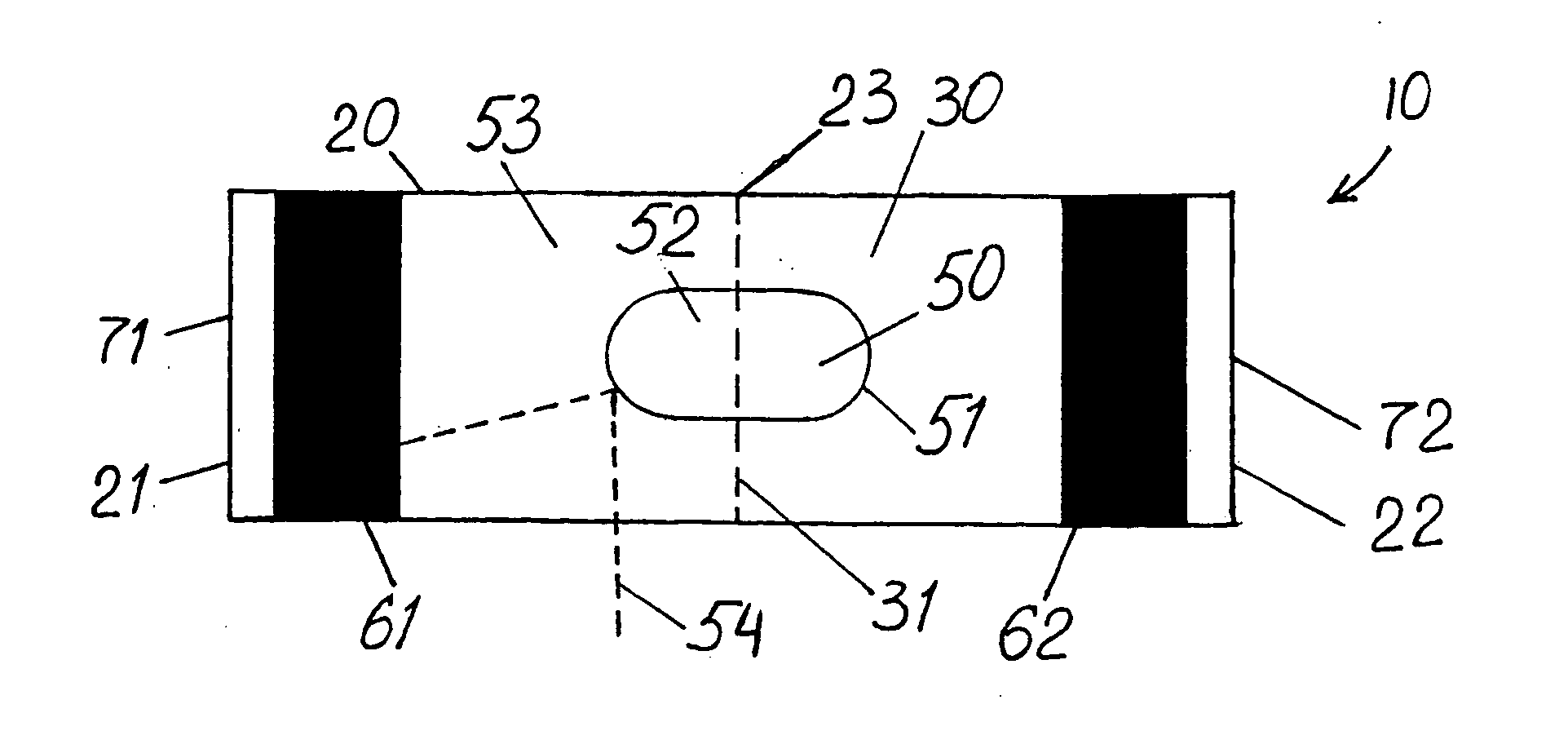

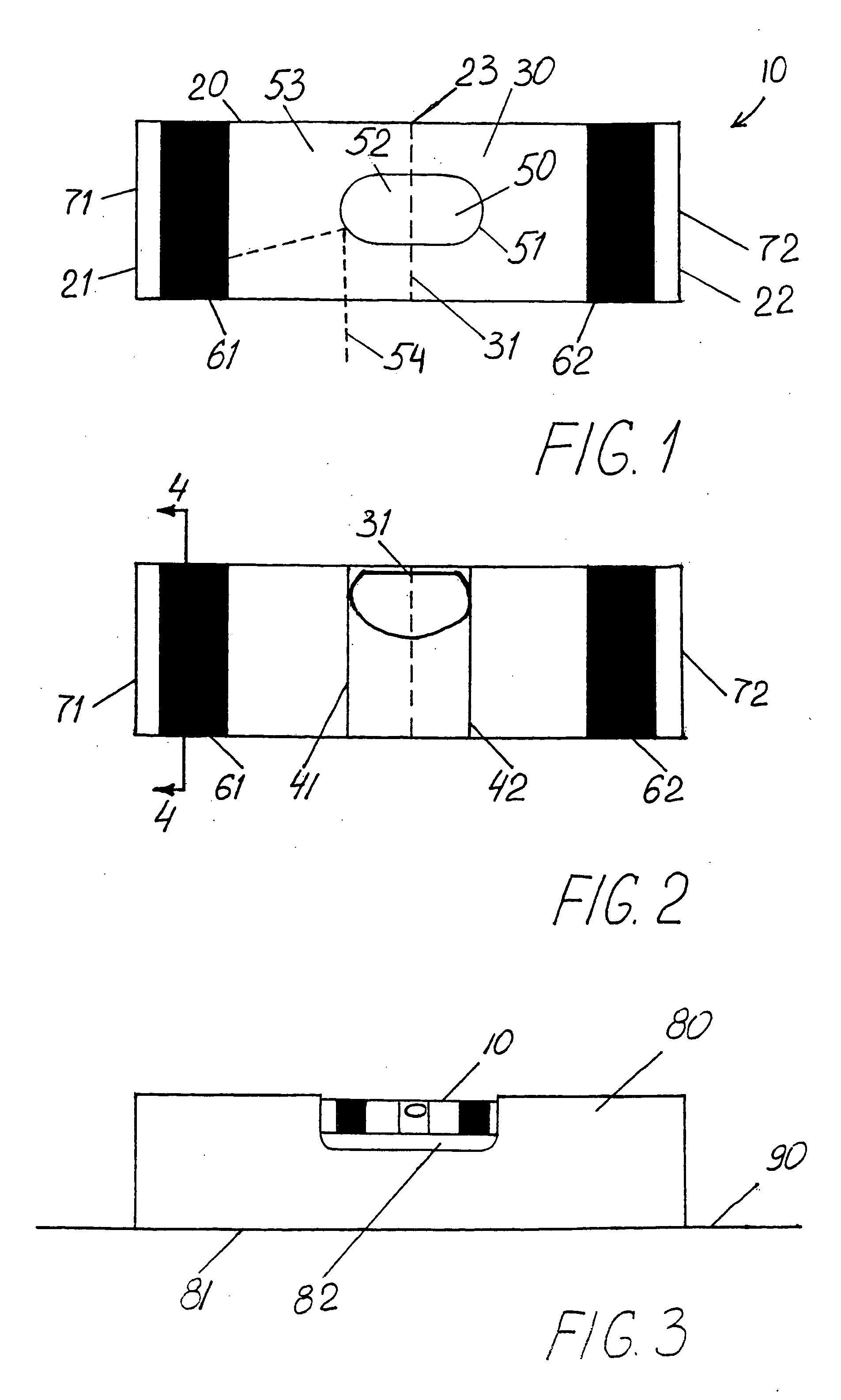

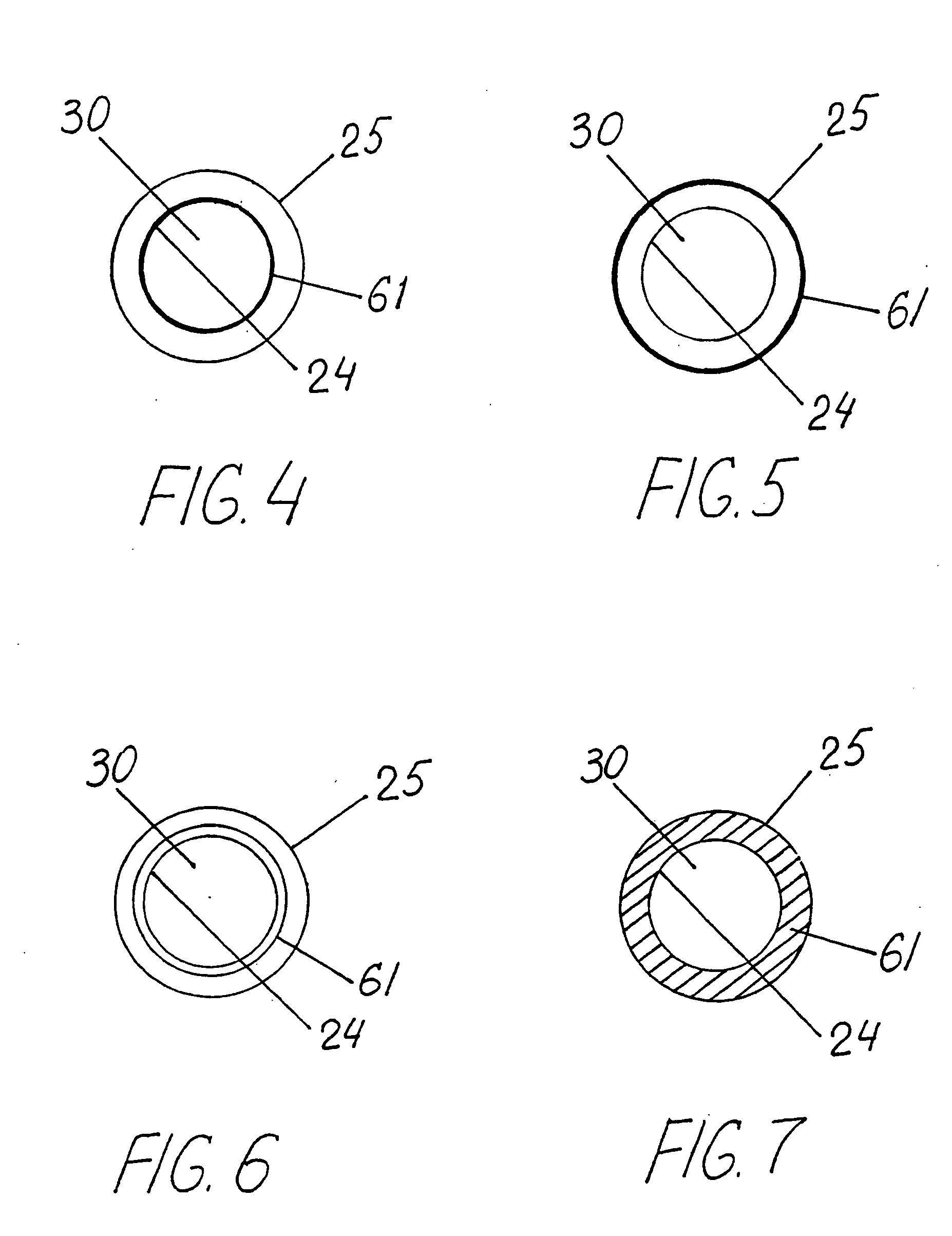

[0035]FIGS. 1 and 2 are overhead views of an embodiment of the vial 10. Vial 10 includes a body 20 having a first end 21 and second end 22 with a midpoint 23 therebetween. Vial 10 is preferably a plastic material such as acrylic, polycarbonate, polystyrene, butyrates or the like, and is transparent. The internal surface of body 20 defines a barrel-shaped cavity 30 such that there exists a cross-section of the cavity 30 which has a maximum diameter. The maximum diameter 31 is preferably positioned near or at the midpoint 23.

[0036] Vial 10 further includes at least one marker ring 40 connected with respect to the body 20, shown as a first marker ring 41 and a second marker ring 42. The marker rings 41,42 are preferably equidistant to the maximum diameter 31. As shown, a bubble 50 is positioned within the cavity 30 at the maximum diameter 31 and between marker rings 41,42. The bubble 50 is defined by a gas-liquid interface 51 with the bubble being gas 52 and the rest of the cavity 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com