End hood extension for a corn header

a corn header and end hood technology, applied in the field of extension of the corn header end hood, can solve the problems of non-resistant corn being more likely to be infested and downed, the corn plant's ears are more likely to fall over the end hood when being harvested, and the device is not easily removable or movable out of the way, so as to reduce the occurrence of corn plants falling off, improve the effect of harvesting efficiency, and reduce the occurrence of corn plants falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

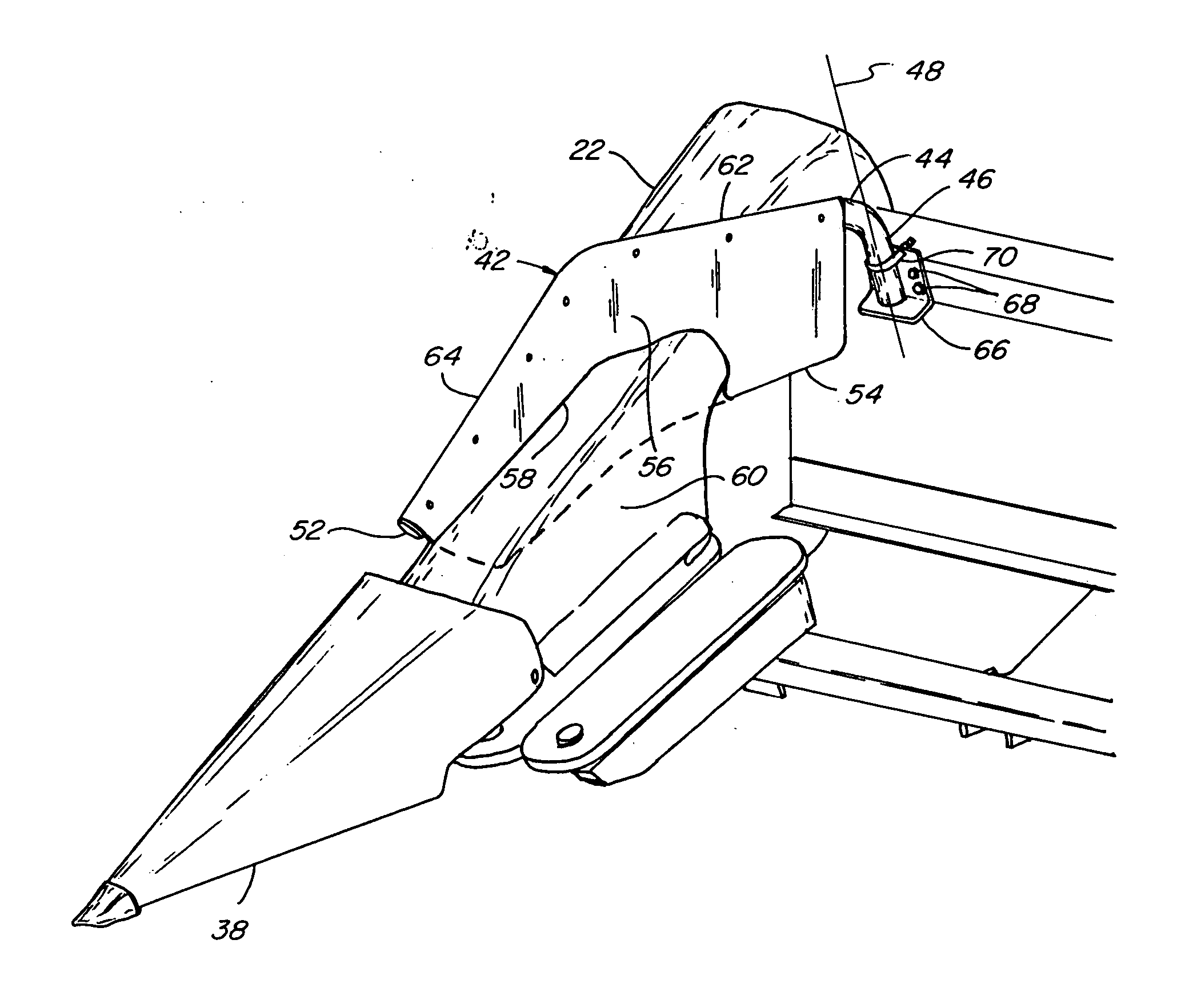

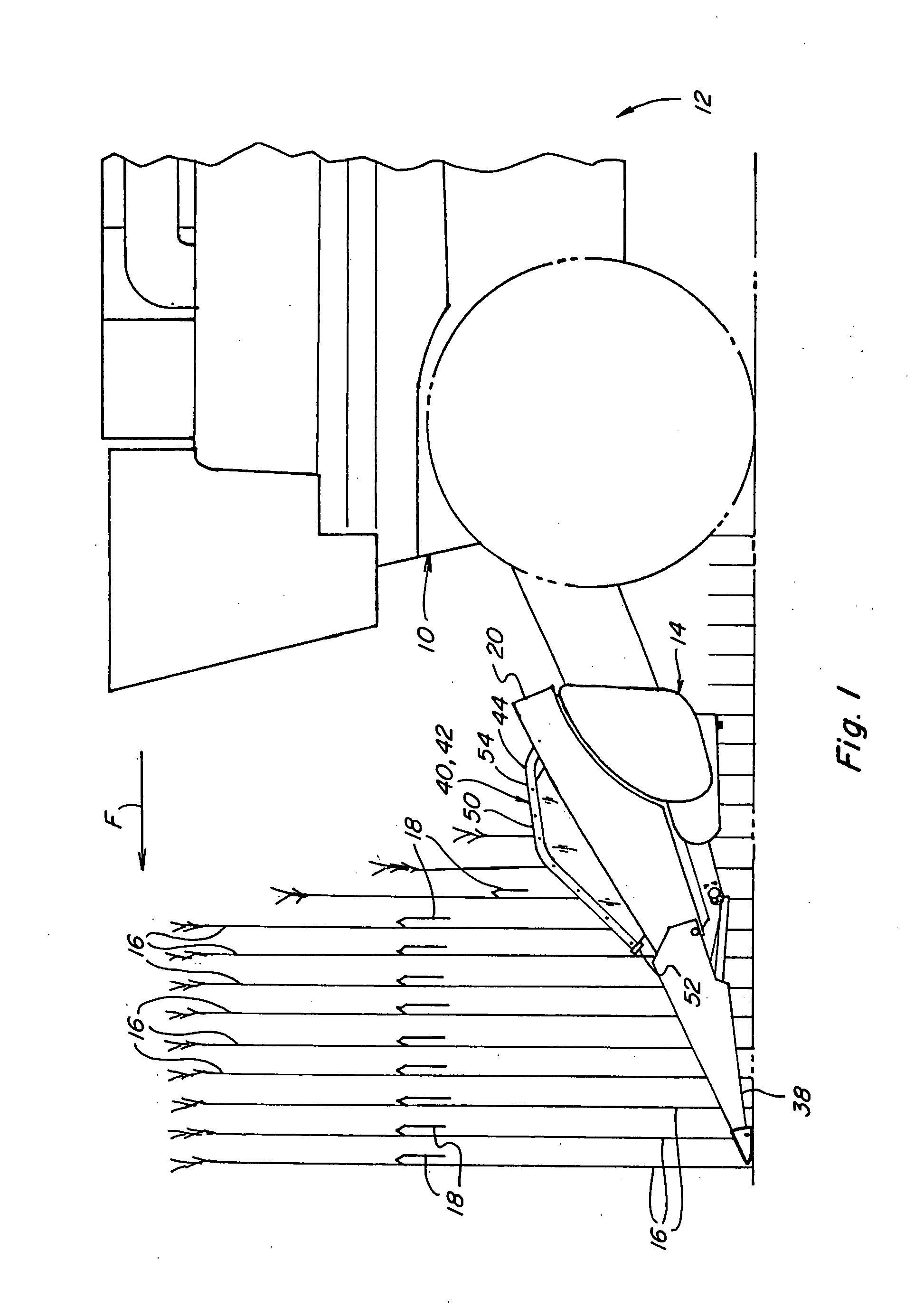

[0014] Referring now to the drawings, in FIG. 1 a forward end 10 of a conventional self-propelled agricultural combine 12 is shown, including a conventional corn header 14 mounted thereto. Combine 12 is illustrated as moving in a forward direction, as denoted by arrow F, over an agricultural field including a plurality of rows of standing corn plants 16, for removing ears 18 therefrom in the well known conventional manner. Referring also to FIG. 2, corn header 14 includes a pair of end hoods 20 and 22 at the opposite sides thereof, which define the width of header 14. As shown in FIGS. 3 and 5, disposed at spaced intervals between end hoods 20 and 22 are a plurality of crop row dividers 24. Adjacent ones of dividers 24 and end hoods 20 and 22 define a plurality of crop gathering channels 26 therebetween, respectively. When moving forwardly over a field, header 14 will be positioned such that crop gathering channels 26 are aligned for receiving respective rows of corn plants 16. Loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com