Breathing bag including integrally formed connector and distensible portions

a technology of connectors and bags, applied in the field of breathing bags, can solve the problems of insufficient stiff or rigid connection of connector portions, insufficient stiff or rigid connection of neck portions, and unwanted costs, and achieve the effect of increasing gas pressur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

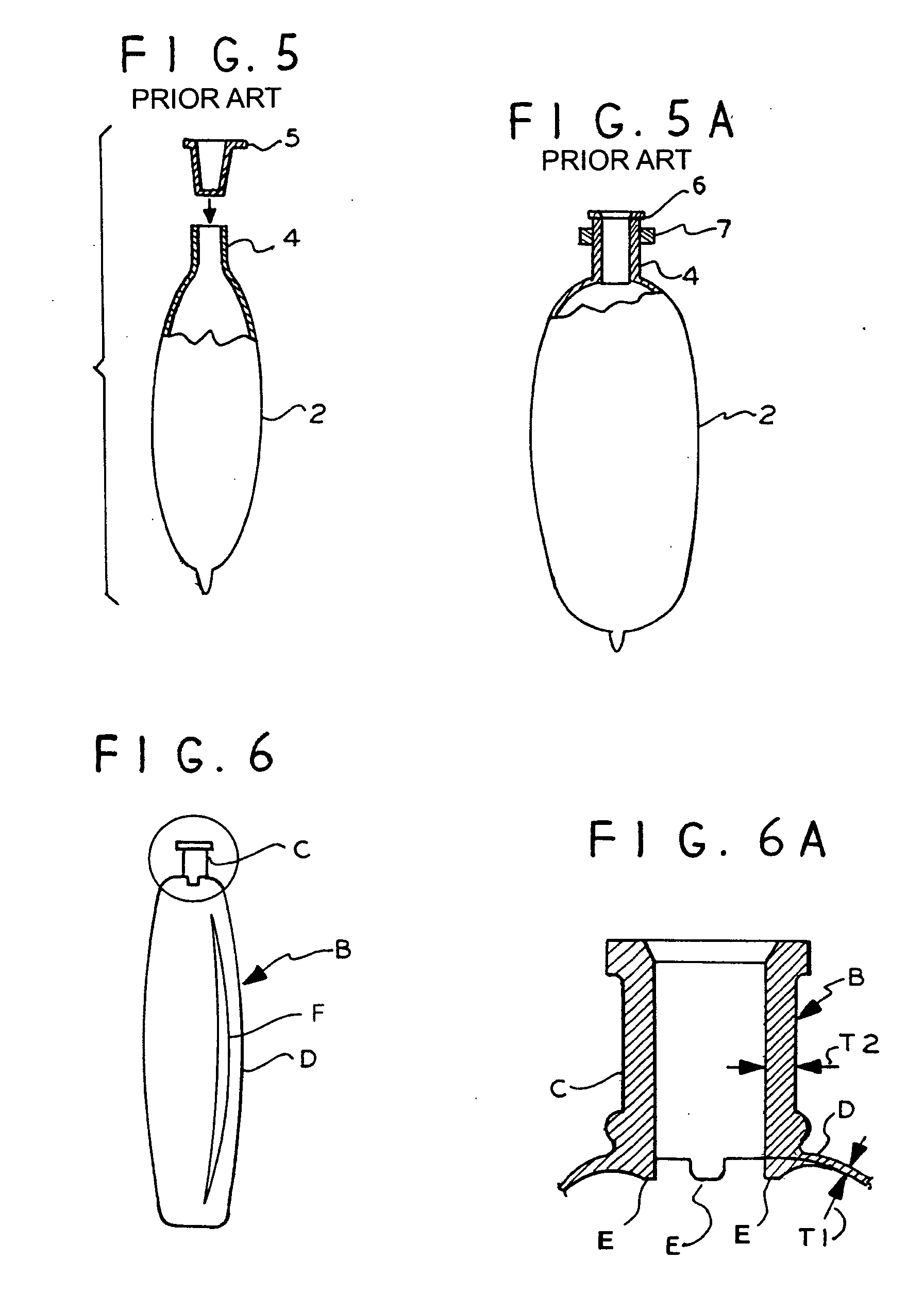

[0023] A breathing bag embodying the present invention is illustrated diagrammatically in FIGS. 6 and 6A and indicated by alphabetical designation B. Breathing bag B includes a generally cylindrical connector portion C and a distensible portion D. The connector portion C is typically sized to connect directly to an ISO 22 mm male fitting and the distensible bag D expands and contracts in the process of delivering, or assisting in delivering, gas to the patient as noted above. As will be better understood from FIG. 6A, the connector portion C has a greater thickness than the thickness of the distensible portion D; the greater thickness of the connector portion C provides it with the strength or rigidity to serve its above-noted connector function. For illustration the thickness of the connector portion C has been exaggerated with respect to the thickness of the distensible portion D in FIG. 6A. In one embodiment, the distensible portion D had a thickness or wall thickness T1 of about...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wall thickness T2 | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com