Venetian blind operated with non-pull cord structure

a technology of pulling cords and venetian blinds, which is applied in the direction of door/window protective devices, building components, constructions, etc., can solve the problems of reducing the safety affecting the safety of children, so as to reduce the parts of assembly and materials cost, and protect the effect of people in the household

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

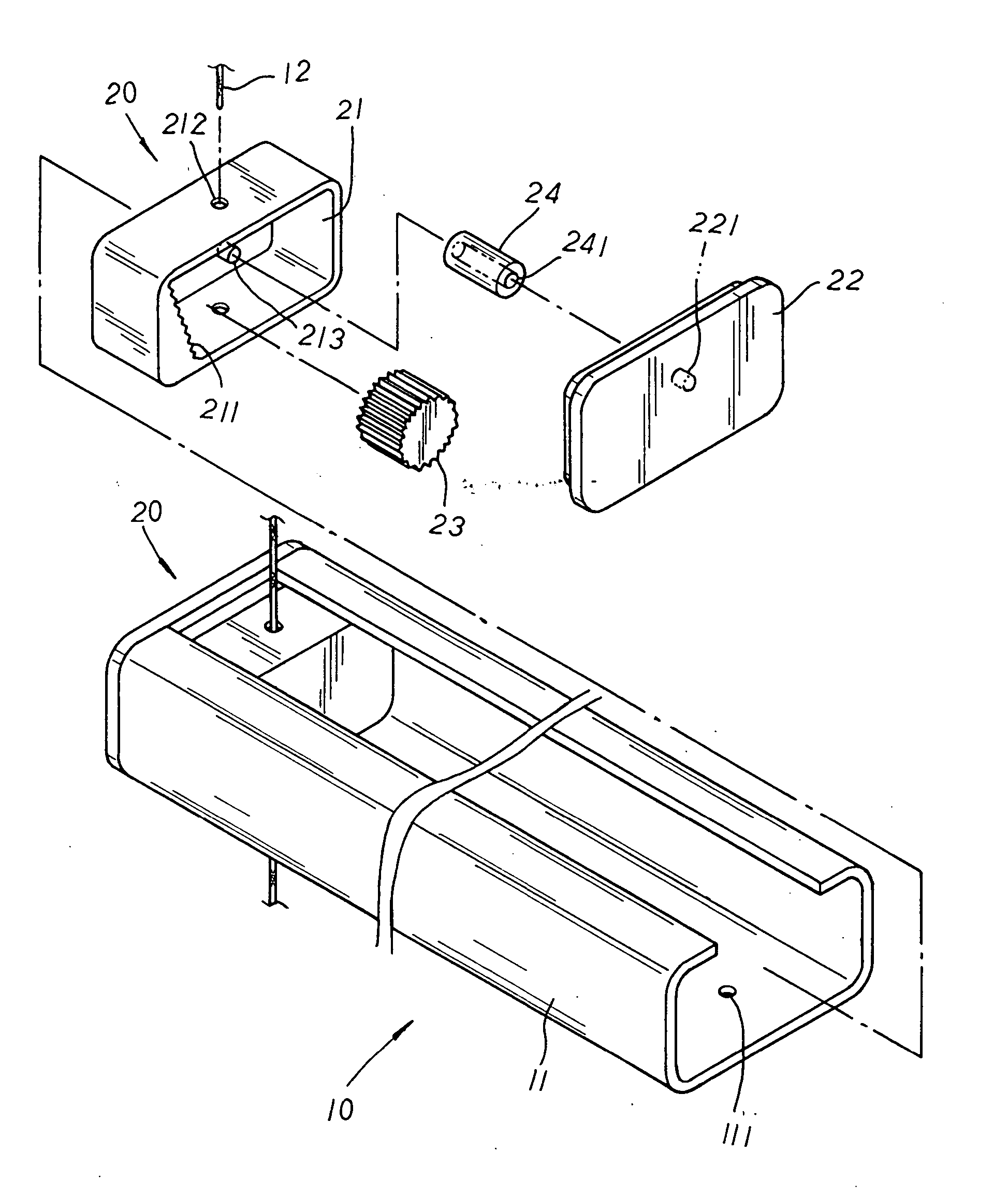

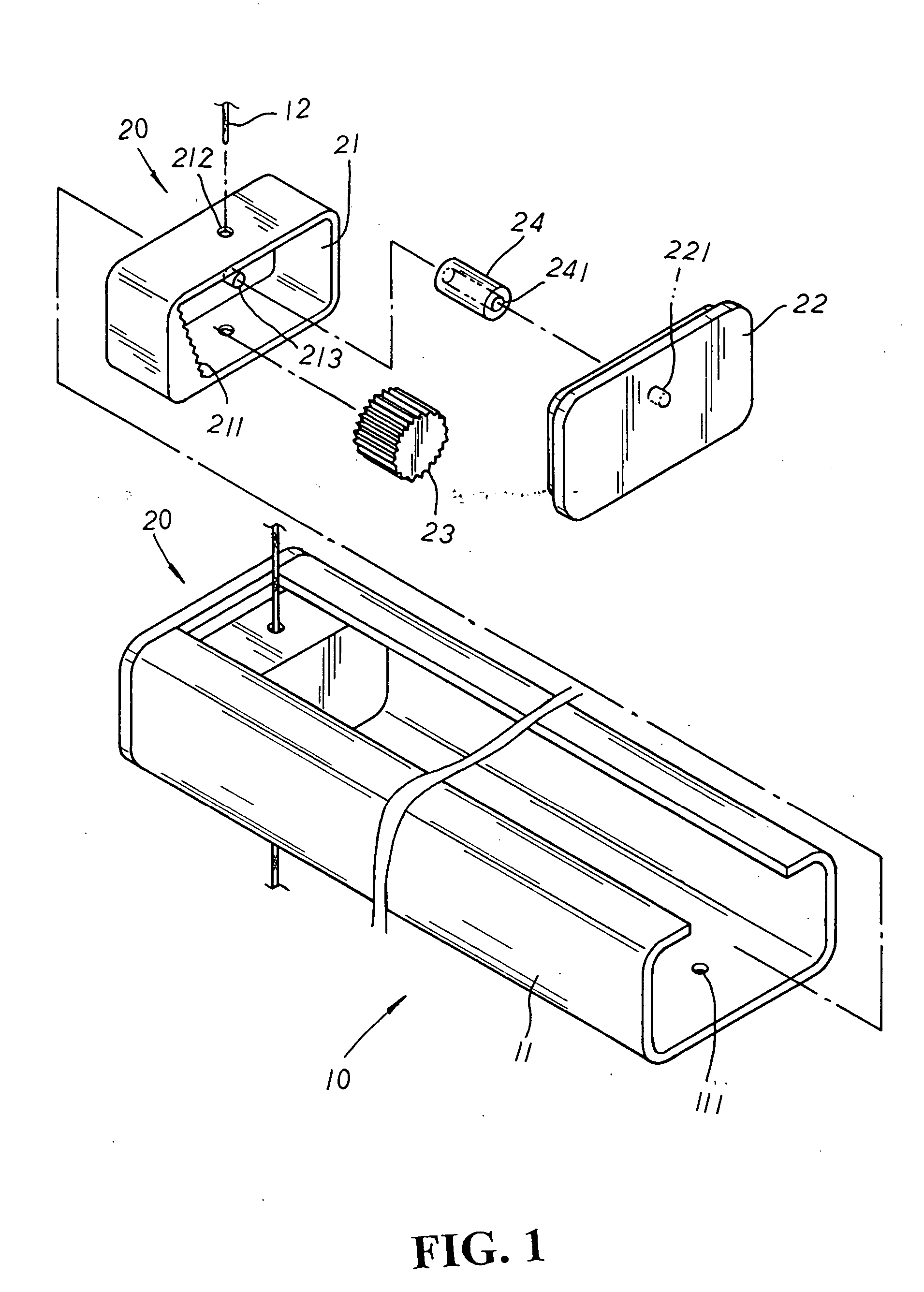

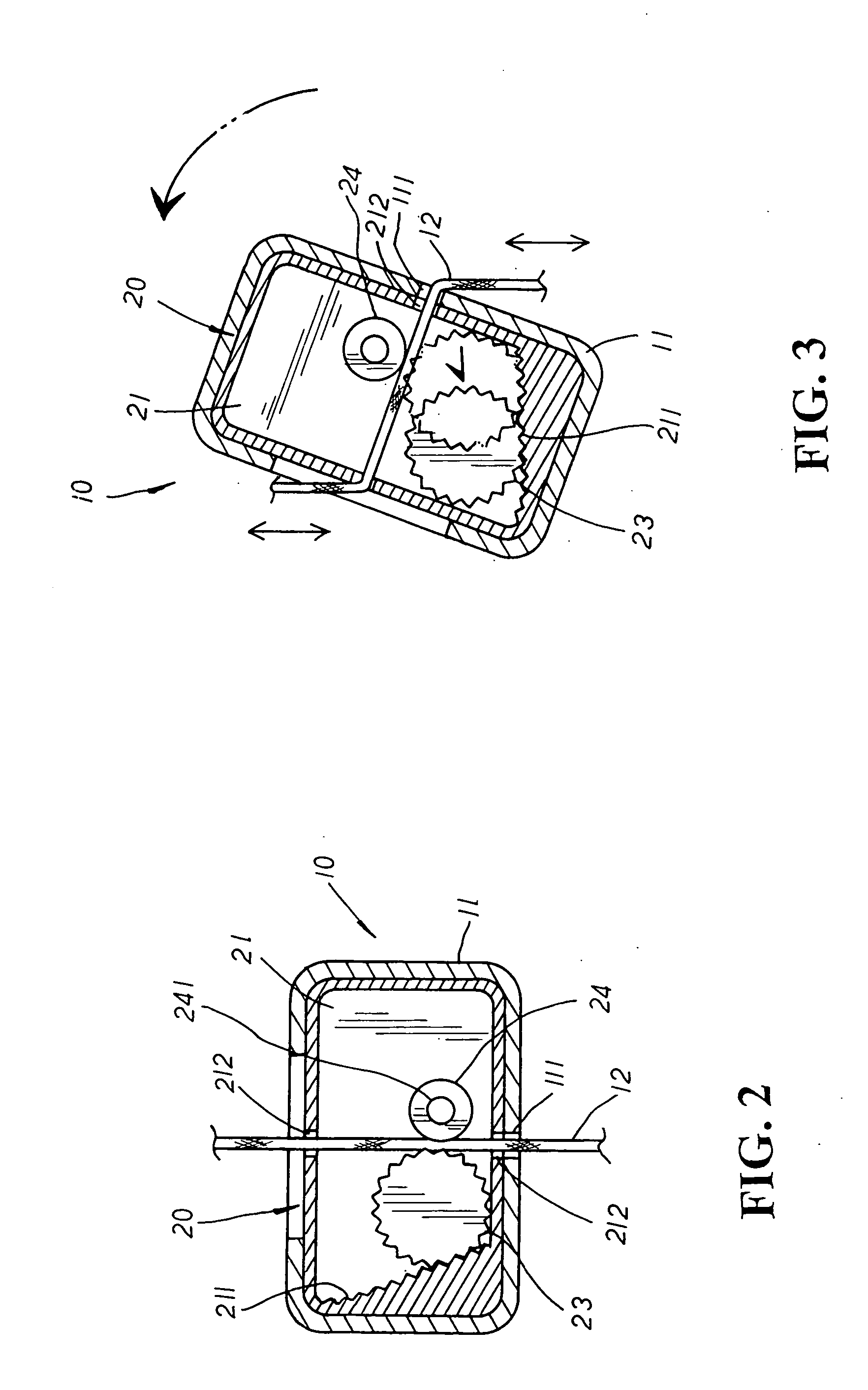

[0010] Please refer to FIGS. 1 to 2 inclusive. The present invention is related to a Venetian blind operated with a non-pull cord structure, comprising a blind embodiment 10, a lower beam 11 having a pivot hole 111 disposed at the bottom side of each end thereon, and a control unit 20 and a sealing cap 22 to be sequentially adapted to each end of the lower beam 11 thereof. The control unit 20 is provided with a housing cavity 21 indented at one side thereof to which the sealing cap 22 is joined at one side in sealing engagement therewith. At one inner side of the housing cavity 21 thereof is disposed a sloped and serrated guiding face 211 correspondingly matched to a retaining gear element 23 adapted at the housing cavity 21 therein. A through hole 212 is disposed at the top and bottom sides of the housing cavity 21 respectively in communication with the pivot hole 111 of the lower beam 11 for a left / right retaining cord 12 led through both lateral sides of the blind embodiment 10 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com