Electronic filter assembly

a technology of electronic filter and assembly, applied in the direction of filter, transient suppressor details, coupling device connections, etc., can solve the problems of additional parts and expense, manual assembly steps, and require additional components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

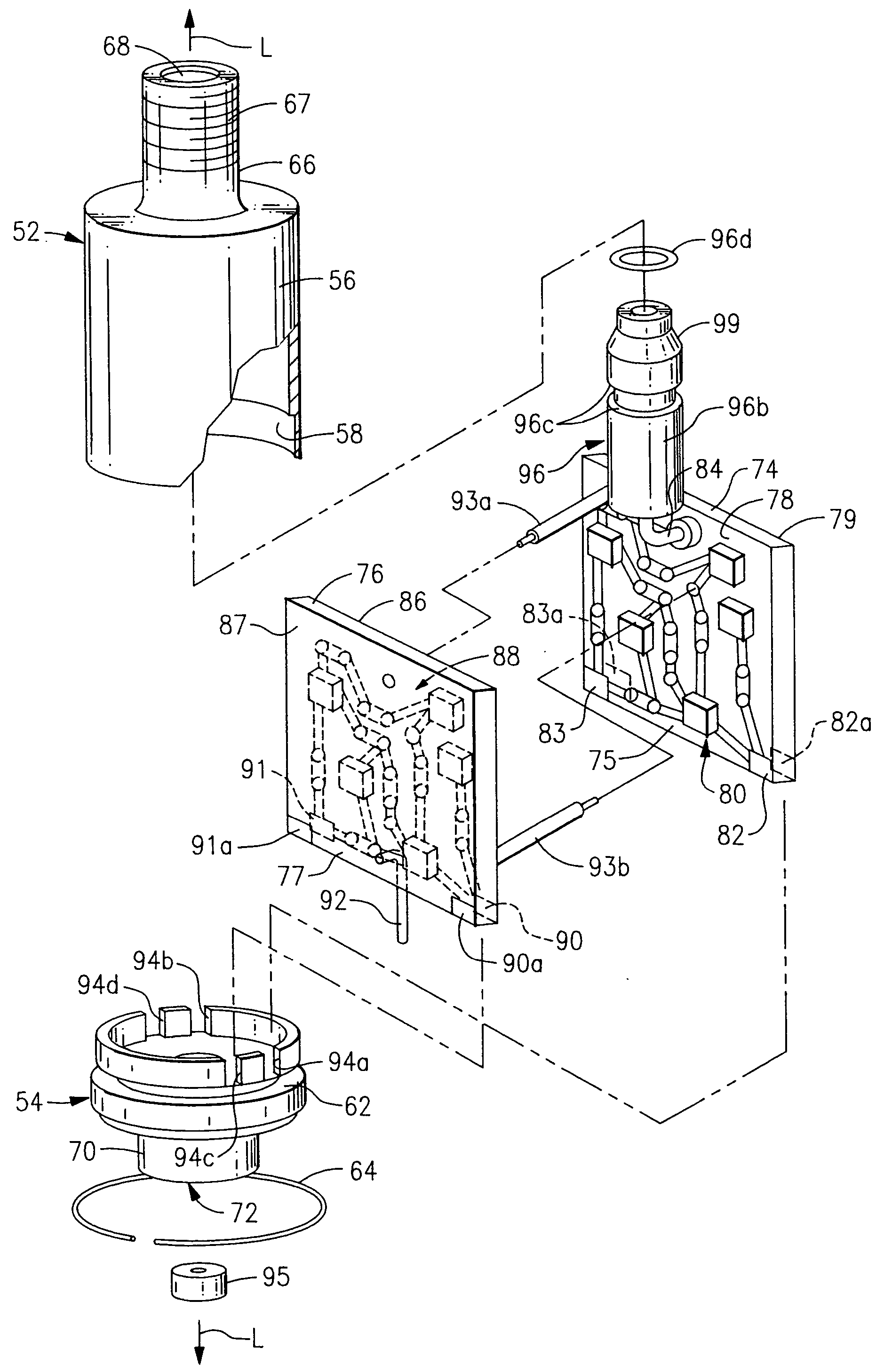

[0028] The filter assembly of the present invention is especially suited for dual (or parallel) path filter circuits. As understood in the art, dual path circuits include at least two separate circuit paths. Examples of dual path filters are diplex, windowed highpass, and some step attenuator filters. Referring now to FIG. 1, there is shown a schematic of a dual path filter circuit 10, having a highpass circuit path 12 and a lowpass circuit path 14. Circuit 10 is a simplified version of a step attenuator circuit described in U.S. Pat. No. 5,745,838 to Tresness et al., incorporated herein by reference. The present invention is not limited to filter assemblies for any particular filter circuit. Circuit 10 is presented only as an example of a dual path circuit. An understanding of circuit 10 is not necessary for an understanding of the present invention.

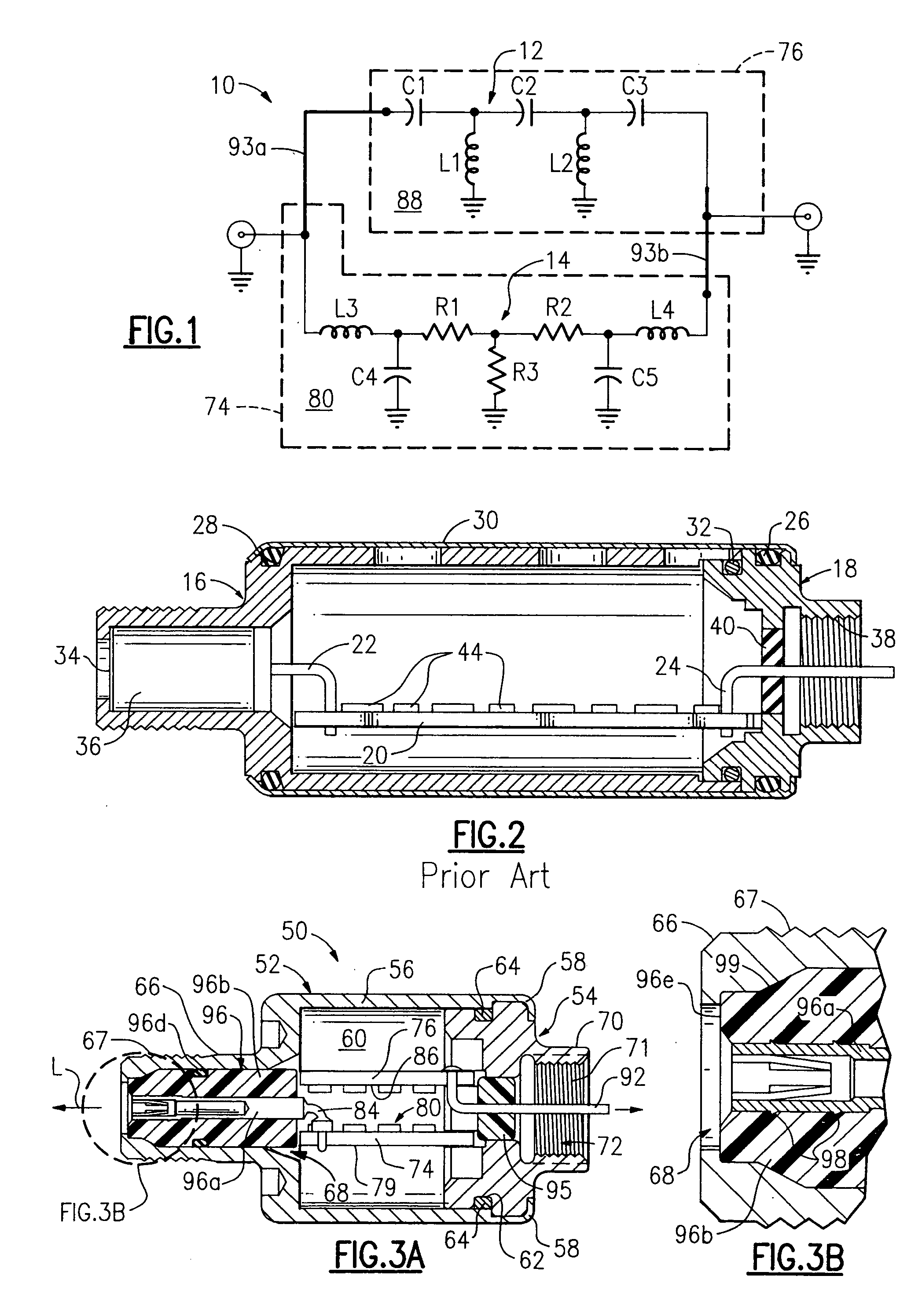

[0029]FIG. 2 shows a sectional view of a conventional filter construction. The construction includes a female terminal cap 16, a male...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com