Improvements in excavator teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

Background of Invention

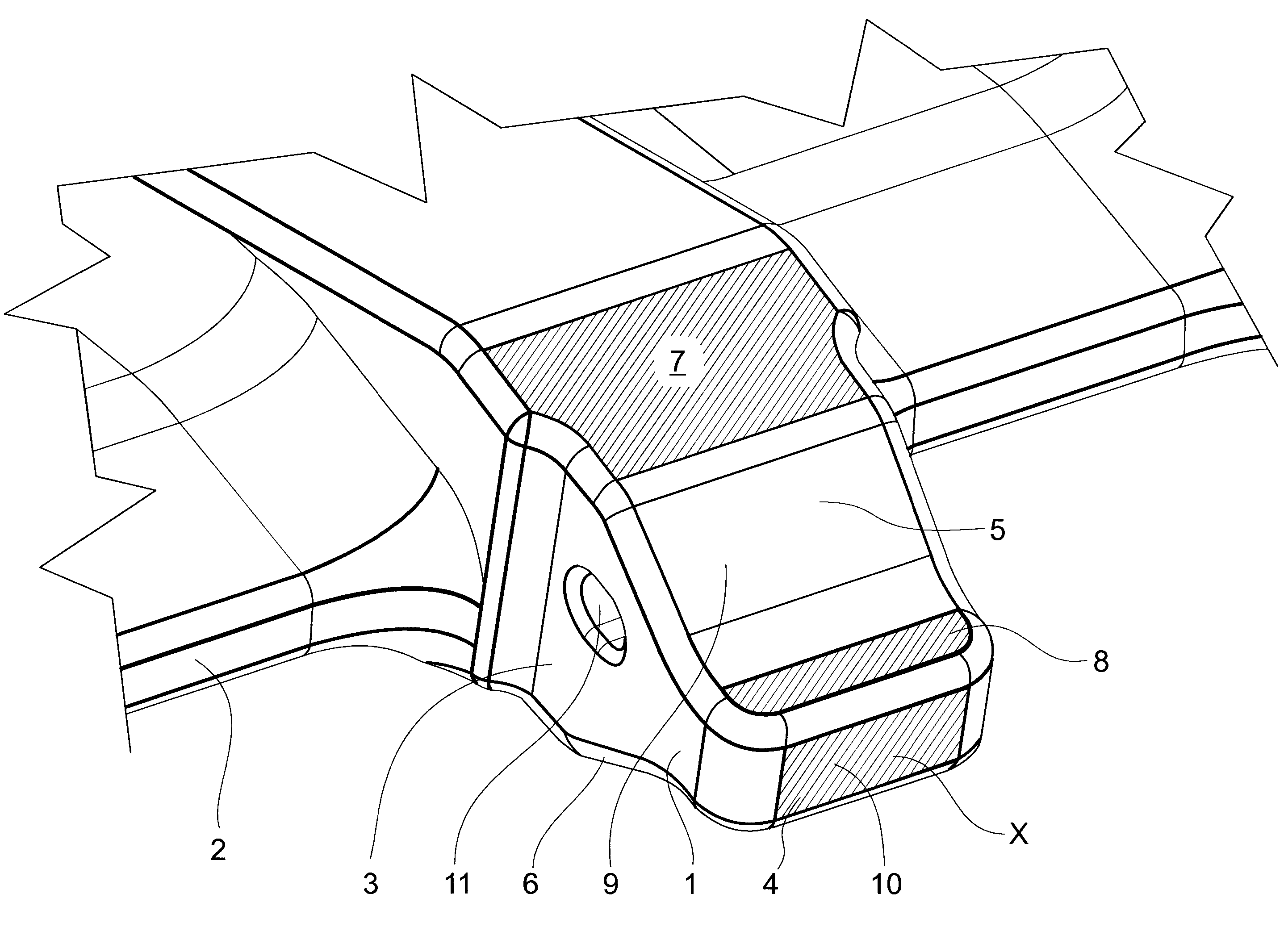

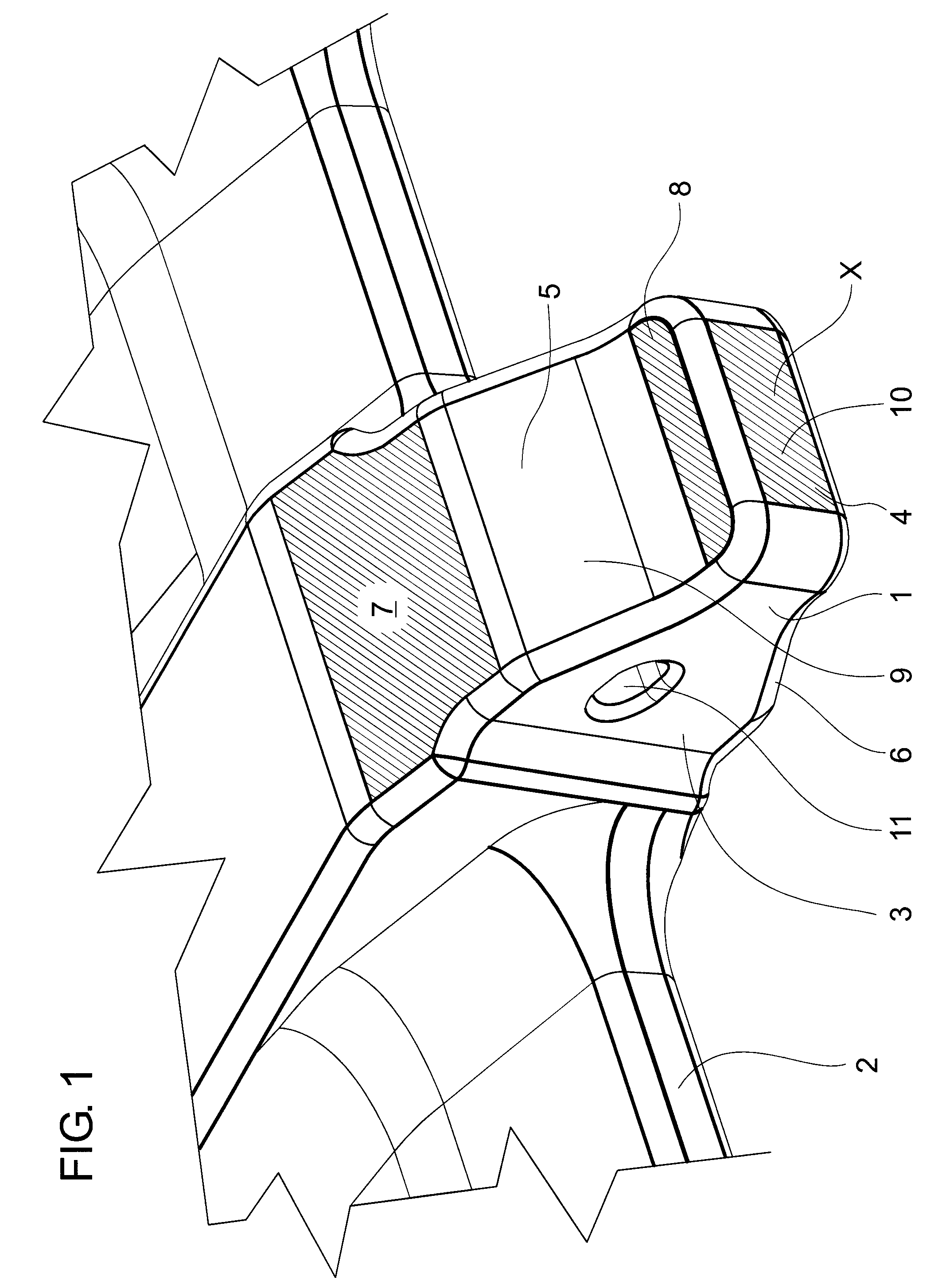

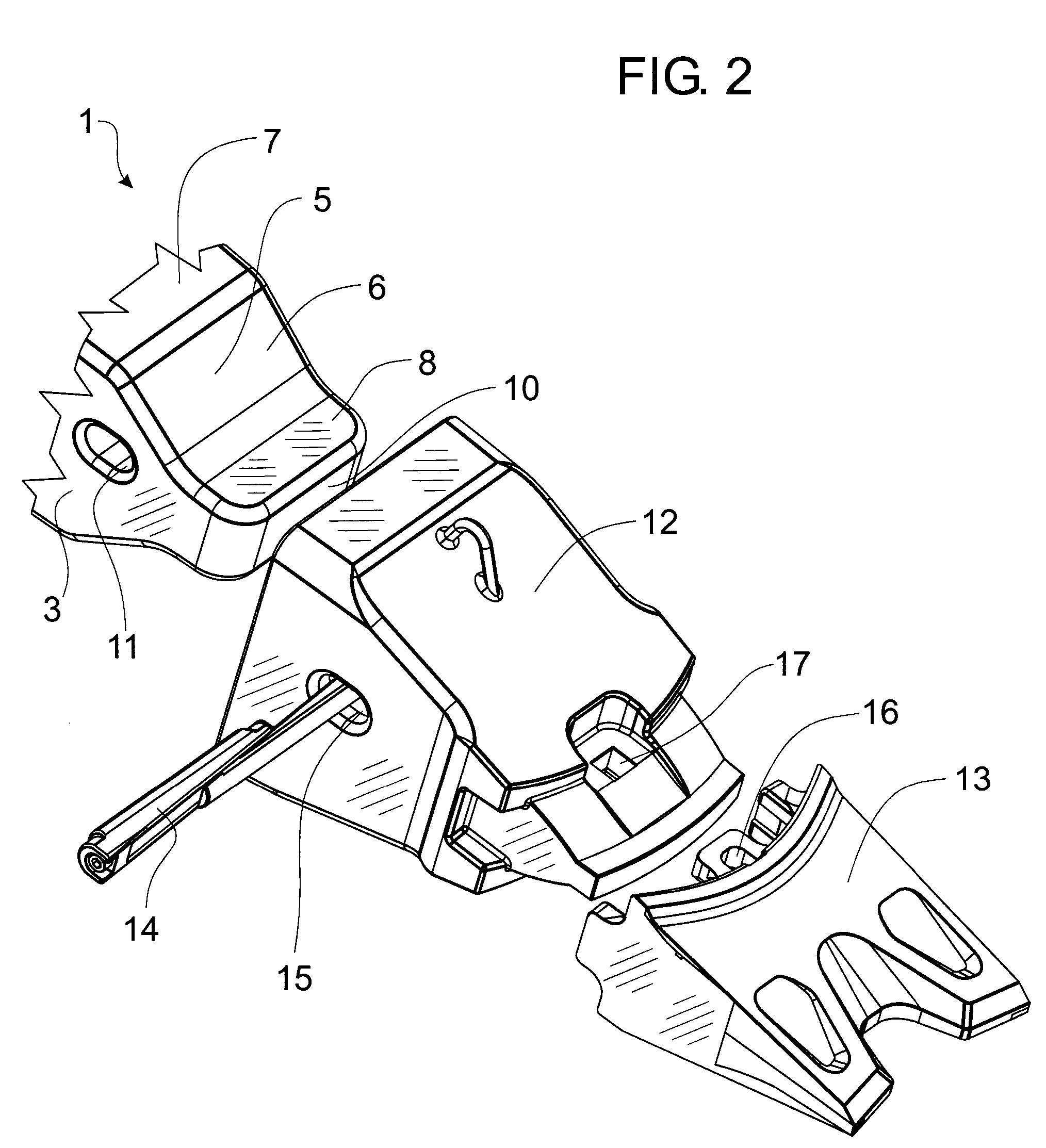

[0001] This invention is concerned with improvements in excavator teeth for earth excavating devices.

[0002] The invention is concerned particularly, although not exclusively, with the mounting of excavator teeth adaptors to adaptor noses on an excavating device such as an excavator bucket or the like.

[0003] Excavating teeth mounted to the digging edge of excavator buckets and the like generally comprise a replaceable digging point, an adaptor body and an adaptor nose which is secured by welding or the like to the digging edge of a bucket or the like. The adaptor has a socket-like recess at its rear end to receivably locate a front spigot portion of the adaptor nose and a locking pin extends through aligned apertures in the adaptor and nose to retain the adaptor in position.

[0004] In use, excavator teeth are subjected to extensive load forces along a longitudinal axis of a tooth as well as in vertical and transverse directions. A snug fit is required between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com