Volumetric shoulder for garments

a volumetric, shoulder technology, applied in the direction of overgarments, apparel, garments, etc., can solve the problems of loose jackets, upward movement of elasticized hems on lightweight jackets, and difficulty in adjusting the hem position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

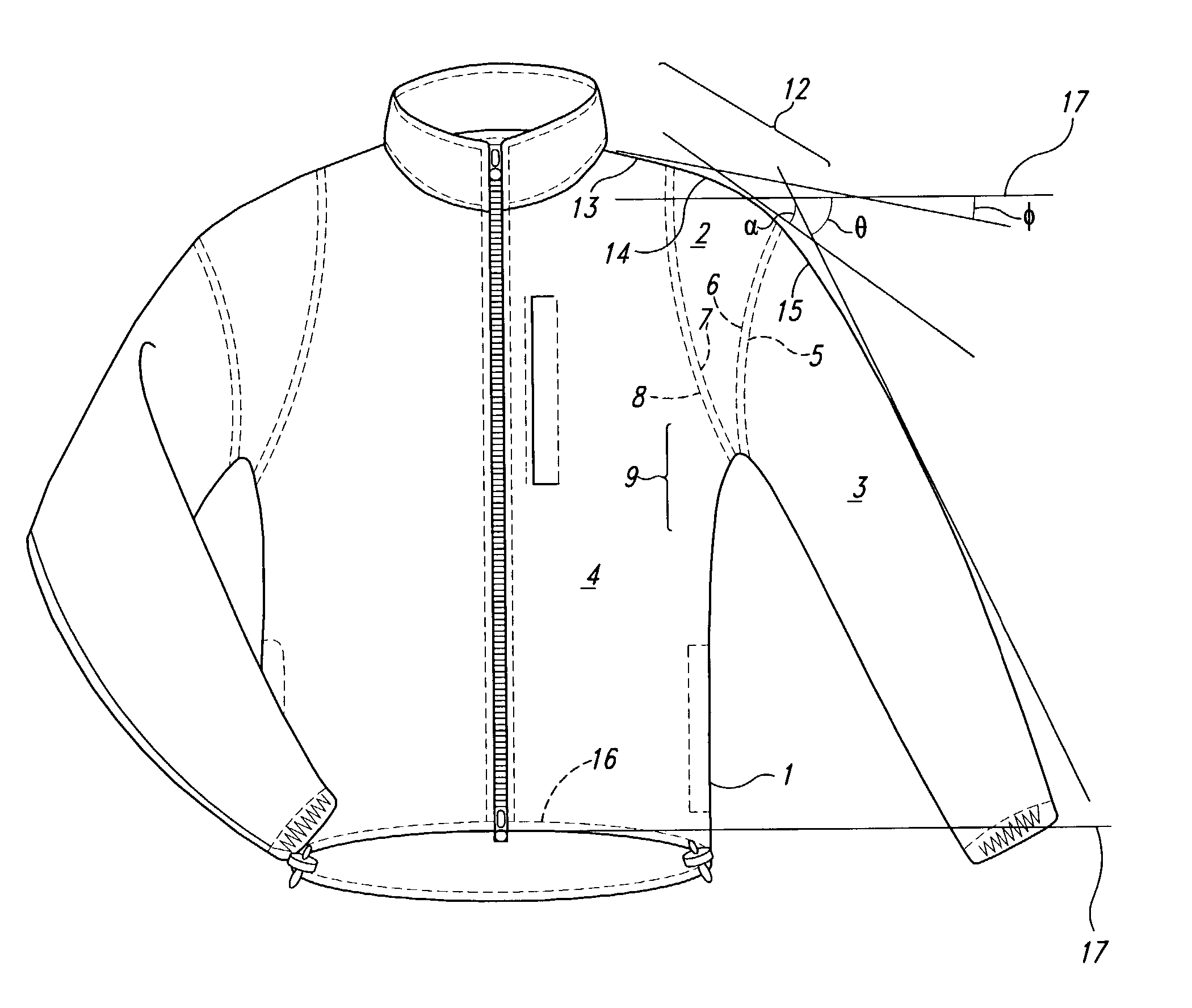

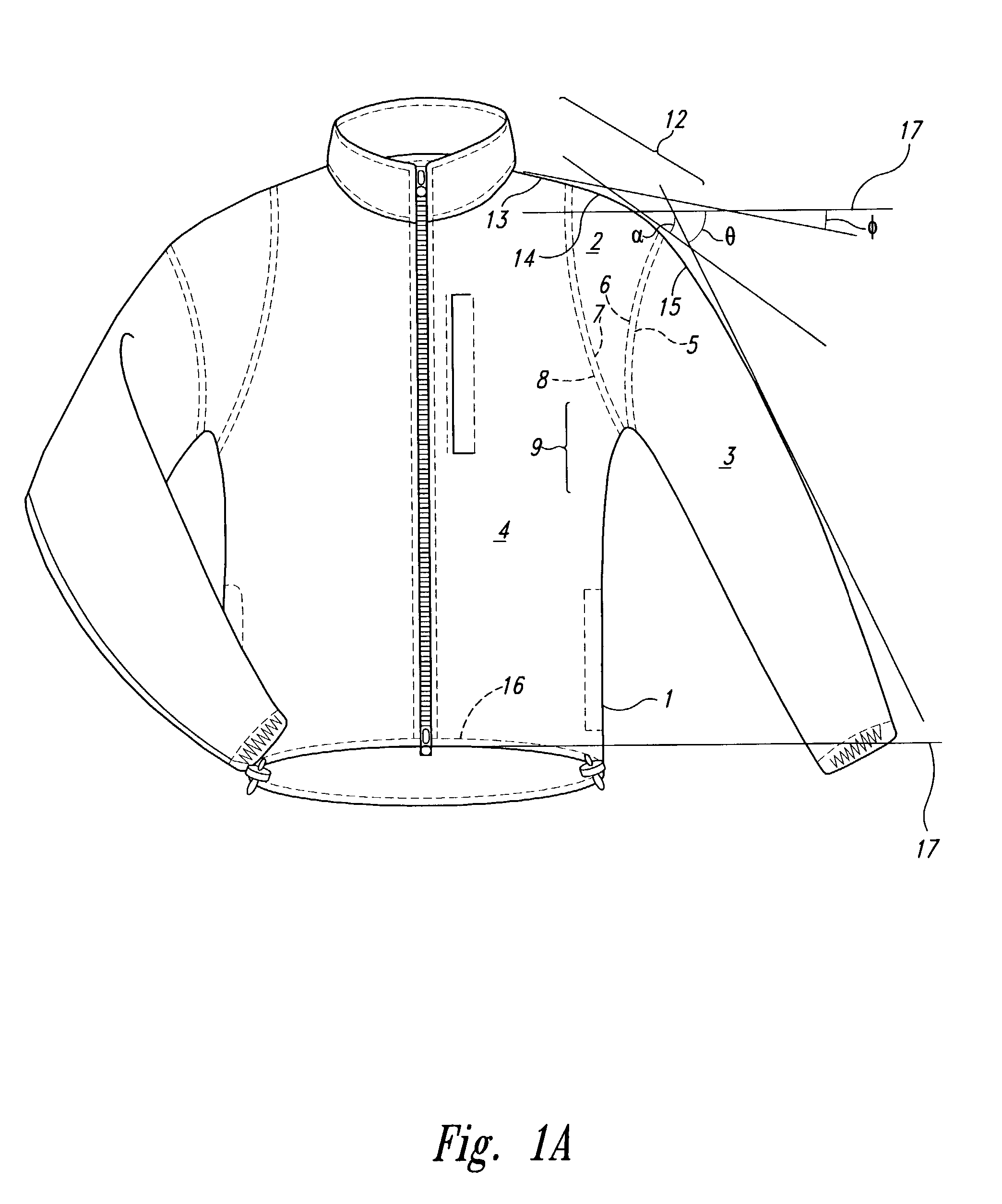

[0034] A first embodiment of the invention is illustrated in FIGS. 1A and 1B. FIG. 1A shows a front view of a jacket 1, with a separate section 2 interposed between a sleeve 3 and a jacket body 4. The separate section 2 wraps over a shoulder area 12, and it includes ends 10 and 11 that are joined together at a seam in an armpit area 9, typically by sewing or by fabric welding, although any other joining method is usable without affecting the utility of the invention. Joining of the ends 10, 11 of the separate section 2 in the armpit area 9 generally provides the best appearance and the best fabric utilization in manufacturing; however, it is entirely possible to break the separate section 2 anywhere else and join the ends together, such as on top of the shoulder area 12, for example.

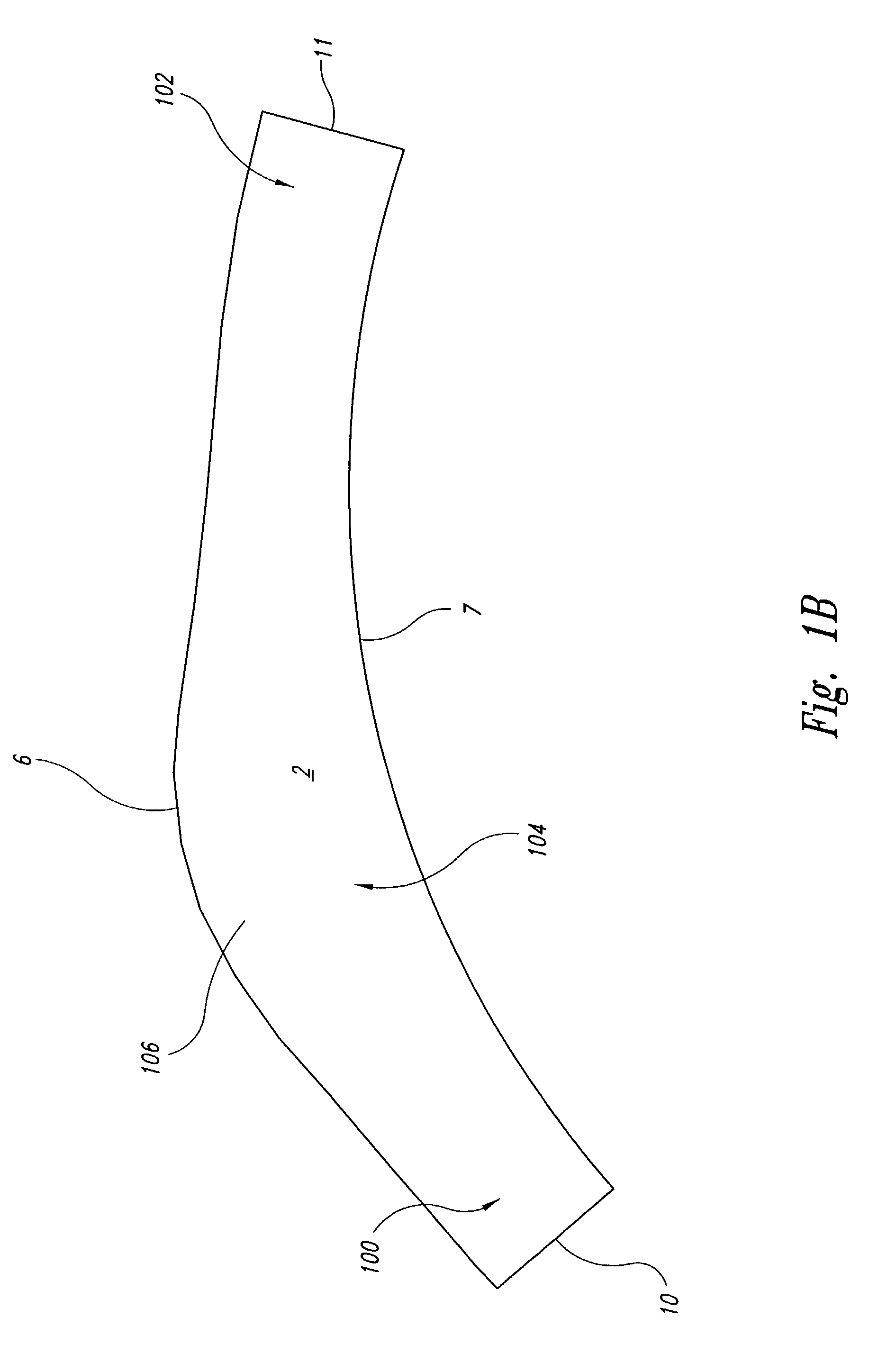

[0035] A typical pattern for the fabric used to make the separate section 2 is shown in FIG. 1B. The section 2 includes opposing longitudinal edges 6, 7 and opposing transverse edges 10, 11. The longitud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com