Piston for automatic transmission

A technology for automatic transmissions and pistons, which is applied in fluid-driven clutches, mechanical-driven clutches, and non-mechanical-driven clutches, etc., and can solve problems such as mutual frictional contact, decreased durability of pistons and frictional engagement elements, and increased power loss in automatic transmissions. Achieve the effects of reducing stress, improving durability, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

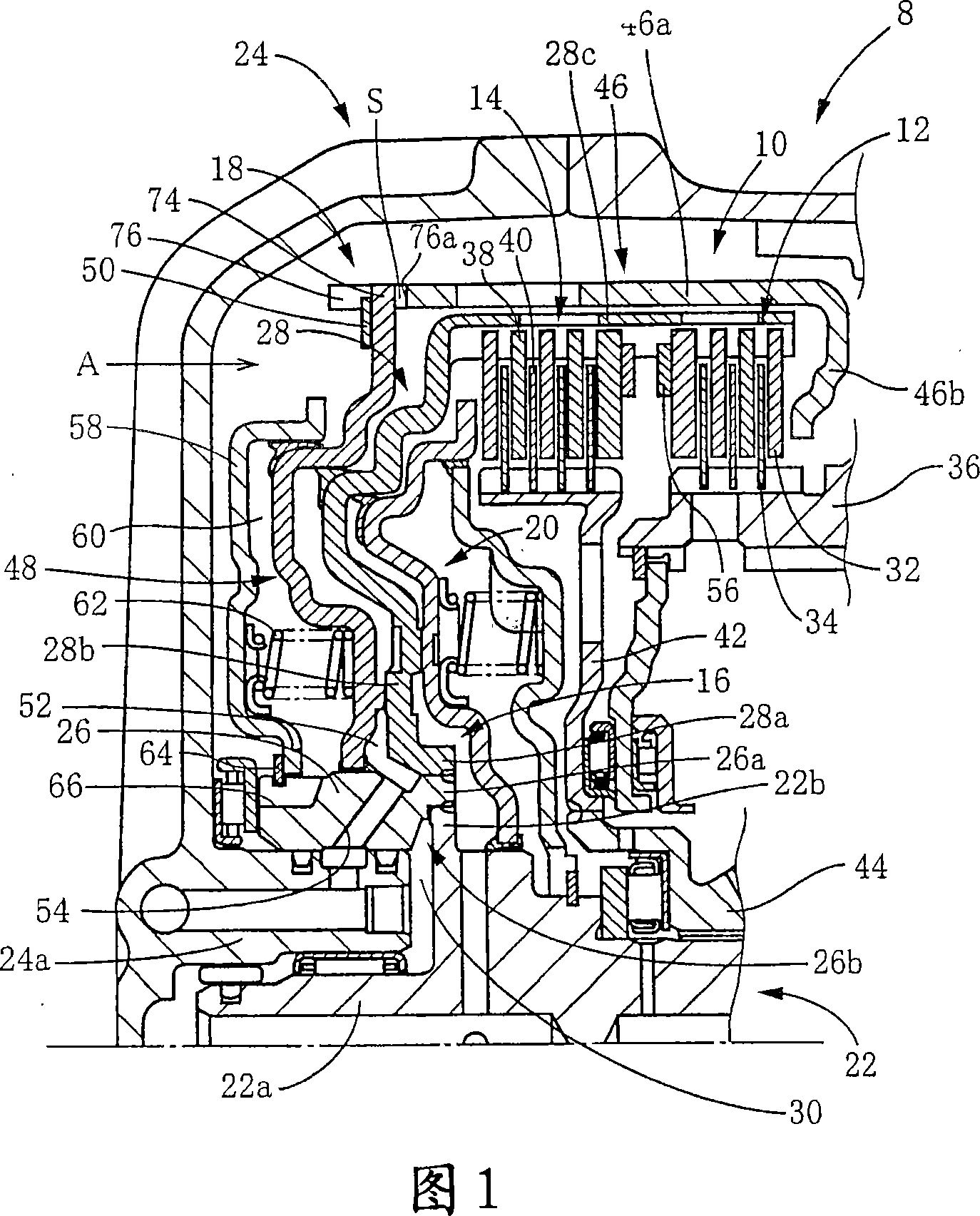

[0028] Referring first to FIG. 1 , a side view in section, there is shown a portion of an automatic transmission 8 provided with a clutch arrangement 10 comprising a piston in the form of a radially outer piston 18 constructed in accordance with one embodiment of the invention.

[0029] The clutch device 10 is of a dual-clutch configuration, and includes: a clutch drum 16 supporting the first set of frictional engagement elements 12 and the second set of frictional engagement elements 14; an outward piston 18 ; and a radially inward piston 20 arranged radially inwardly of the clutch drum 16 .

[0030] The automatic transmission 8 has a housing 24 and an input shaft 22 rotatably supported by the housing 24 at its end 22a. The input shaft 22 has a flange portion 22b located near the end portion 22a in an axial position. The flange portion 22 b extends radially outward perpendicular to the axis of the input shaft 22 . The input shaft 22 is a turbine shaft of a torque converter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com