Composite insulator and its production

A composite insulator and manufacturing process technology, applied in the direction of insulators, electrical components, circuits, etc., can solve problems such as difficulty in large-scale production, high labor intensity of workers, and large amount of manual operations, so as to achieve good product quality, eliminate hidden dangers in operation, The effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

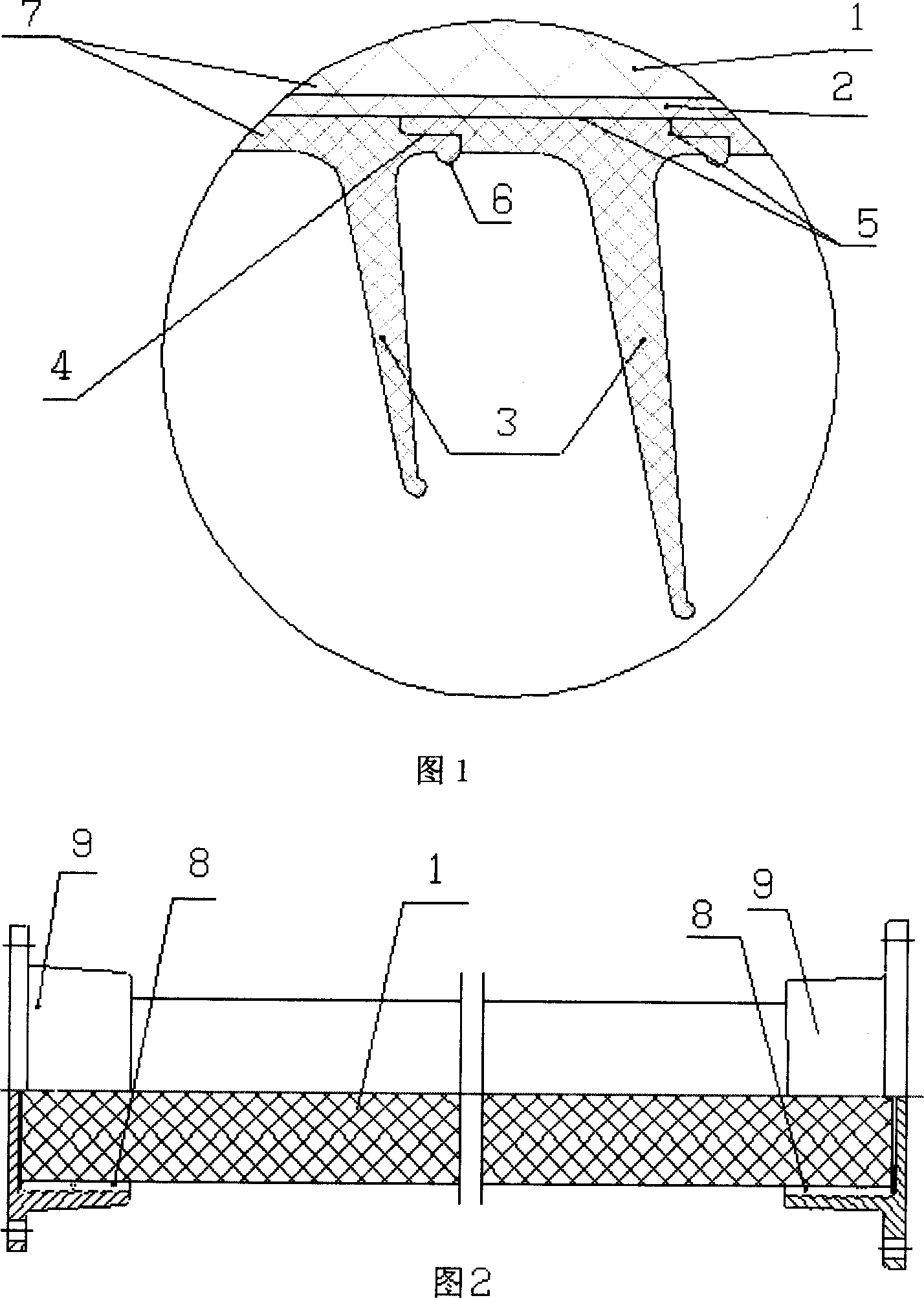

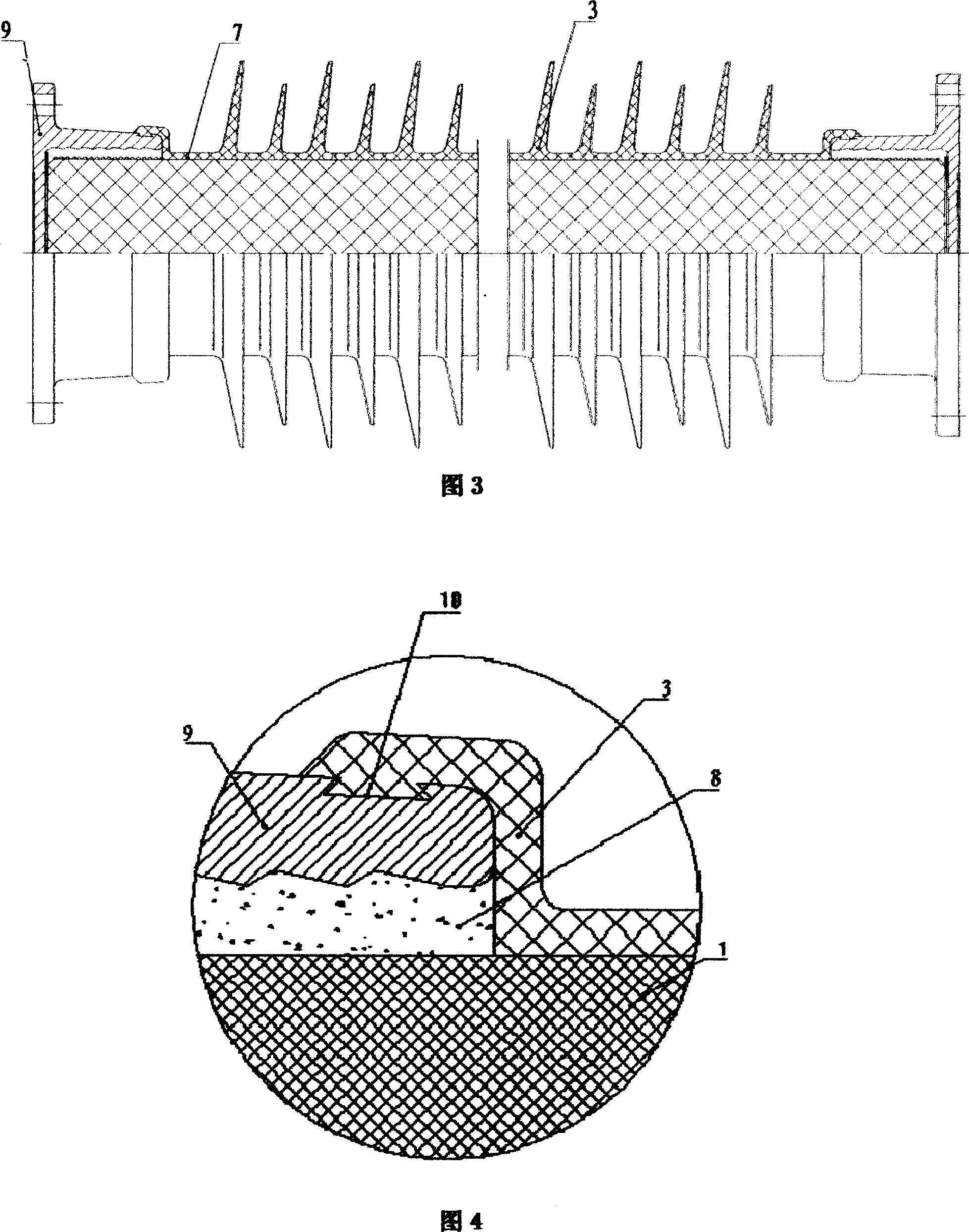

Embodiment 1

[0047] Embodiment 1 is a production process of continuously gluing the metal 9 at both ends. It is generally a process that can only be realized when the single-time production capacity of the equipment owned by the manufacturing company at least basically meets the height requirements of the unit product. The production of composite insulators The process is carried out according to the following steps: as shown in Figure 2, 1. Surface treatment of the glued parts at both ends of the porcelain mandrel 1 and the glued cavity of the metal 9 at the end, that is, after brushing with high-grade gasoline (such as 120#) Diluted asphalt paint to form a buffer layer; 2. The metal 9 at both ends of the porcelain mandrel 1 is glued with commercially available cement adhesive 8. Generally, the selected one is based on the mechanical strength requirements of the product and the operating voltage level. The grade and formula of cement are different. The grade of cement ranges from Portland ...

Embodiment 2

[0050] Example 2 is the equipment that some enterprises do not have a single production capacity. Therefore, it is possible to complete the production and manufacture of unit products only after two rounds of circulation processes. Its terminal metal 9 is glued first when the terminal metal 9 at one end is glued. Its procedure is:

[0051] 1) Prepare the surface treatment of the glue-mounted part of the porcelain mandrel 1 and the end metal 9 of one end;

[0052] 2) Glue the end metal 9 at one end first;

[0053] 3) Surface treatment of the plastic-mounted part of the end metal 9 of the glue-mounted porcelain mandrel 1;

[0054] 4) Preliminary vulcanization of the umbrella cover;

[0055] 5) Prepare the glue-mounted part of the porcelain mandrel 1 and the surface treatment of the glue-mounted cavity of the end metal 9 at the other end;

[0056] 6) Glue the metal 9 on the other end;

[0057] 7) Surface treatment of the ceramic mandrel 1 and the metal 9 at the two ends;

[00...

Embodiment 3

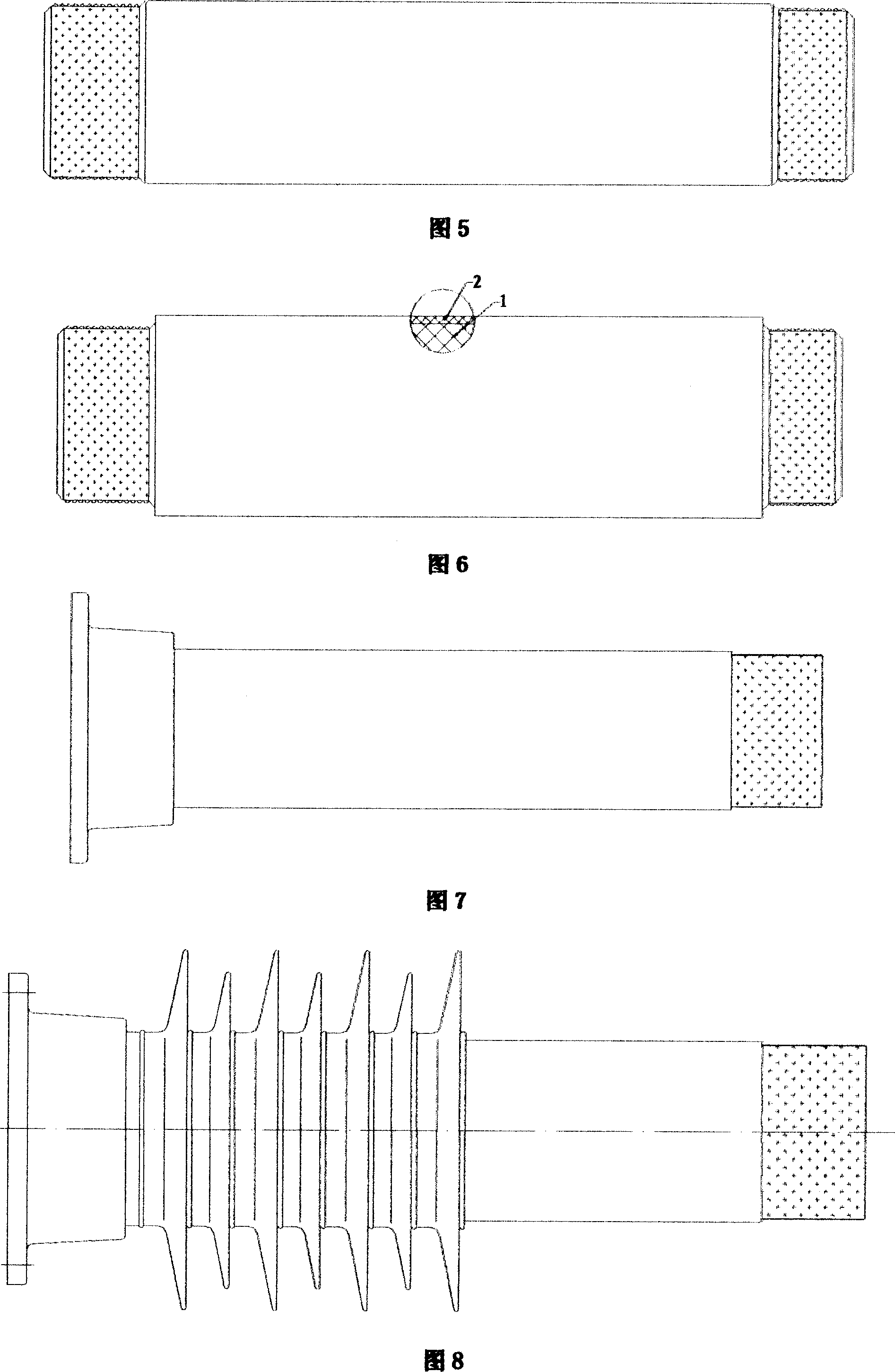

[0060] Embodiment 3 is that the production and manufacture of the unit product may be completed only after multiple times (or called "subsection vulcanization") process, and its operation is:

[0061] 1) Prepare the glued part of the porcelain mandrel 1 and the surface treatment of the metal 9 glued cavity at one end;

[0062] 2) Glue the end metal 9 at one end first;

[0063] 3) Surface treatment is carried out on the vulcanization molding part of the glued porcelain mandrel 1 and the end metal 9 of this end;

[0064] 4) Preliminary vulcanization of the umbrella cover;

[0065] 5) Treat the surface of the vulcanized part, that is, carry out mandrel 1 treatment step by step;

[0066] 6) Sequentially delay the initial molding of vulcanization;

[0067] 7) Prepare the glue-mounted part of the porcelain mandrel 1 and prepare the glue-mounted cavity surface treatment for the end metal 9 of the other end;

[0068] 8) Glue the end metal 9 on the other end;

[0069] 9) Perform s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com