Crude coal slime separating water medium fluidized bed apparatus

A sorting device and fluidized bed technology, applied in the field of coarse coal slime sorting device, can solve the problems of increased sorting cost, equipment wear, large floor area, etc., and achieve improved sorting effect and precision, and long service life , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

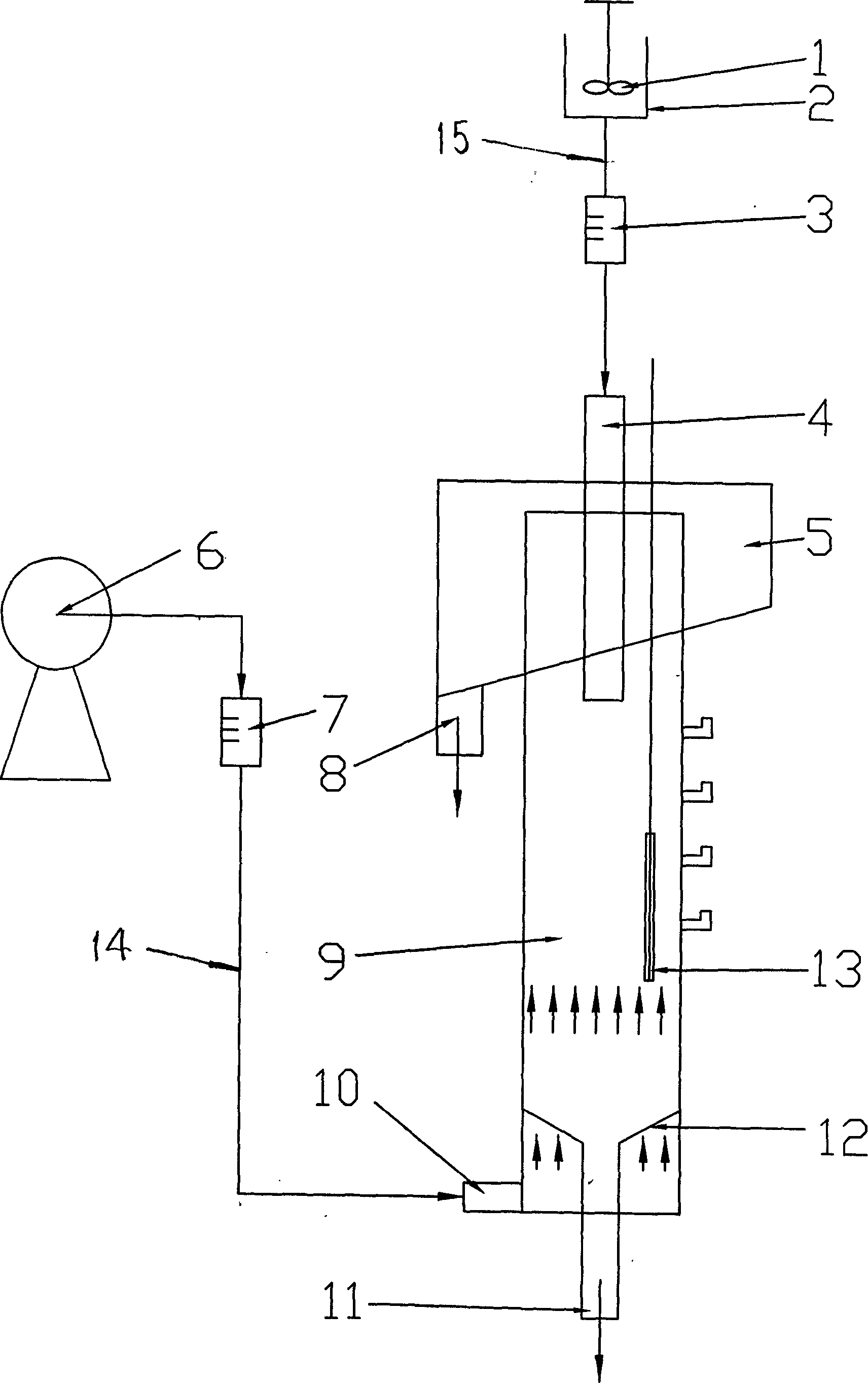

[0009] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The water-medium fluidized bed coarse coal slime separation device includes a water-medium fluidized bed sorter 9, a feeding pipe 4 is arranged inside the upper part of the water-medium fluidized bed separator 9, and a feeding box is arranged above the feeding pipe 4 2. The two ends of the feed pipeline 15 are respectively fixedly connected to the lower part of the feed box 2 and the upper end of the feed pipe 4; The wall is sealed and fixed on the upper part of the water medium fluidized bed separator 9, and the upper end plane of the overflow tank 5 is higher than the upper end plane of the water medium fluidized bed separator 9; The lower part of the inner cavity of the water-medium fluidized bed separator 9 is fixedly connected to the upper end of the bottom outlet 11; a water inlet 10 is provided on the bottom side of the water-medium fluidized bed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com