Small-sized micro-cable-laying device

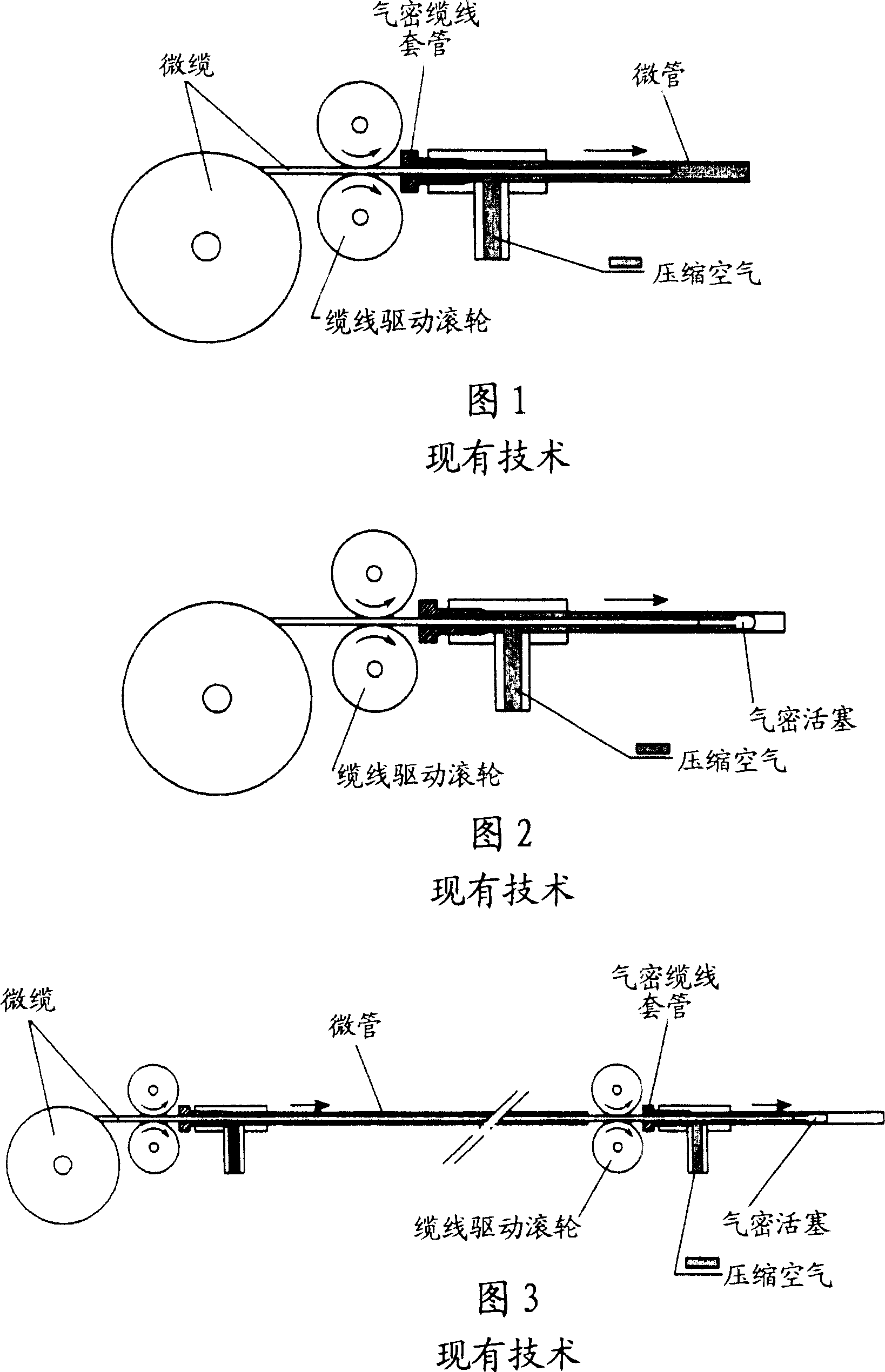

A fiber optic, friction-driven technology for fiber/cable installations, instrumentation, optics, etc., that solves the problems of not always being able to install cable ducts, air leakage, overall size and weight that cannot be easily handled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

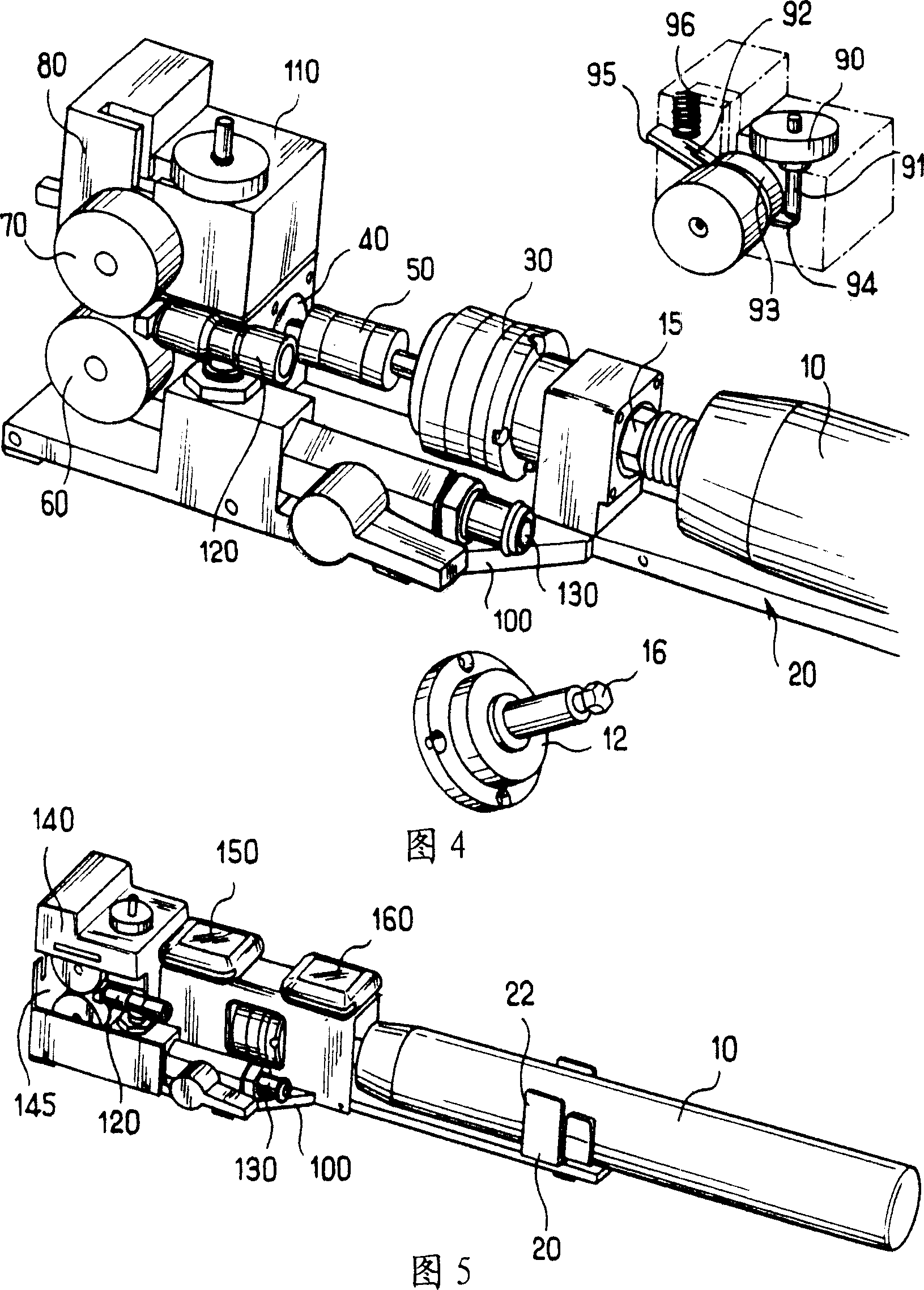

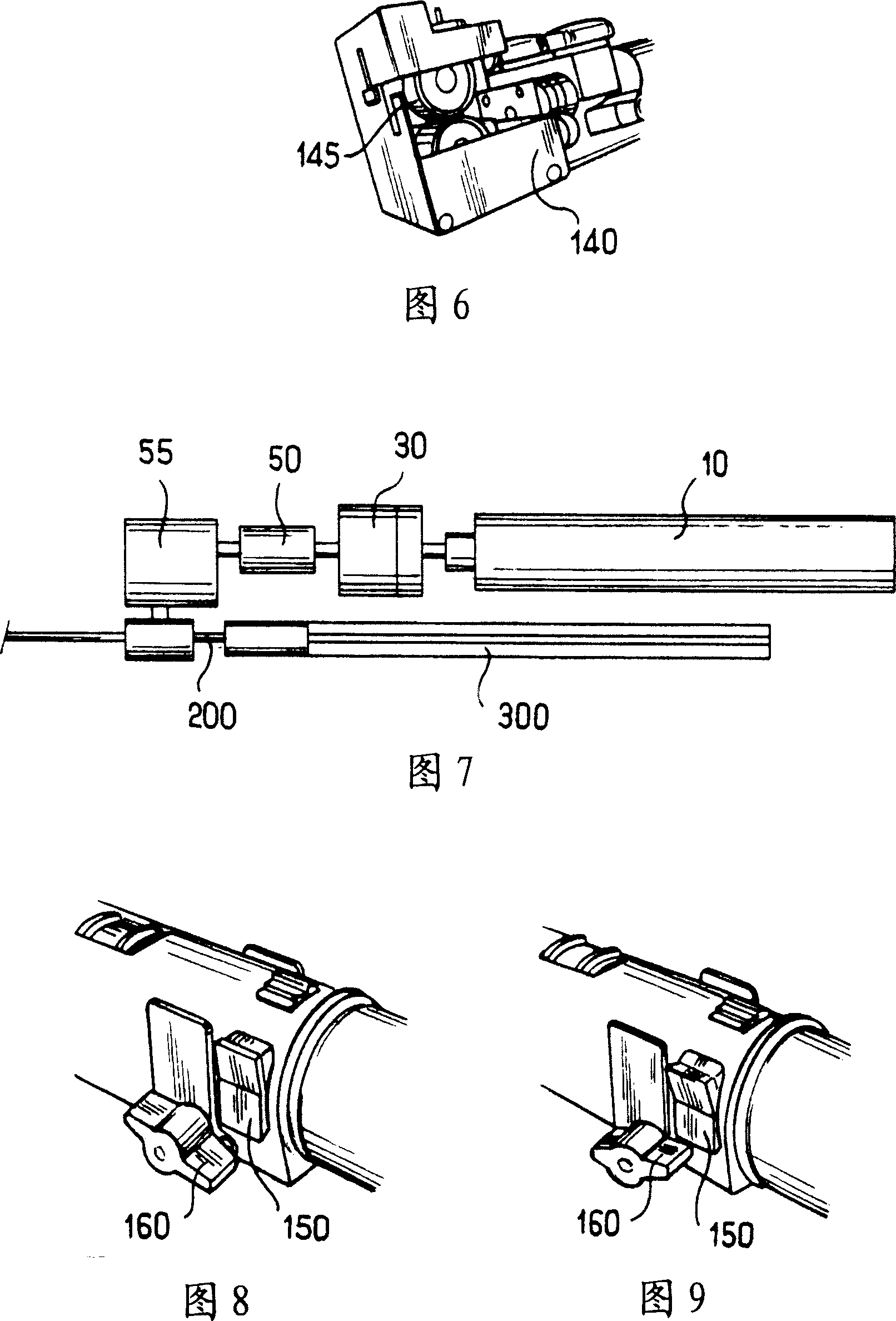

[0024] The devices described here are suitable for use in buildings. This device imparts motion to the cable and protects the cable.

[0025] The components of the device are designed and selected to make the device as compact as possible.

[0026] The cabling device is also light in weight, which facilitates its handling and use.

[0027] Thus, the cable laying device can be used in cable ducts with small dimensions and / or in cable ducts that are relatively difficult to access.

[0028] This example is designed to have a power supply from an interchangeable battery and is in the form of an ordinary handheld screwdriver body.

[0029] The screwdriver body 10 is held on a support 20 of the device which holds the motor in position, here in the form of a U-shaped member 22 clamping the two straight sides of the screwdriver. The U-shaped member prevents the screwdriver from rotating when subjected to reaction forces from the various components driven to rotate.

[0030] In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com