Louver distribution of raising pneumatic stability

A technology of stability and layout, applied in the field of turbomachinery, can solve problems such as the potential limitation of mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

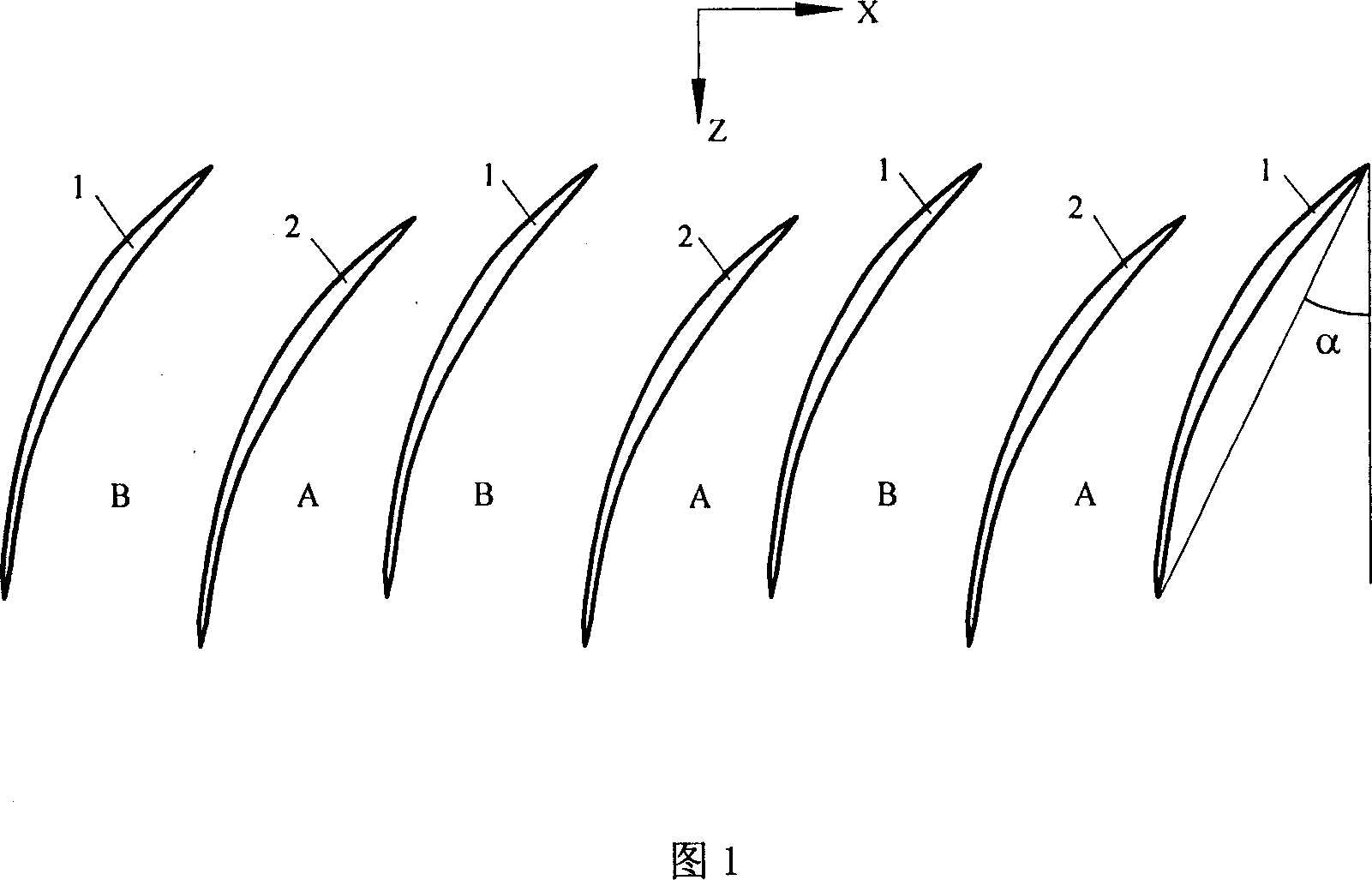

[0014] In this embodiment, the front edges of the same row of blades along the circumferential direction, that is, in the X direction, are arranged alternately in an axial direction, that is, in the Z direction.

[0015] The leading edge of blade 2 in the axial position moves backward relative to the leading edge of blade 1 in the normal position along the axis of the compressor for a certain distance, and the moving distance is 7% of the axial chord length of the blade, wherein the axial chord length is taken as the normal position The width of the blade in the axial direction. In this embodiment, the profile of the blade 2 at the backward position is exactly the same as that of the blade 1 at the normal position, and the installation angle changes to 0°.

Embodiment 2

[0017] In this embodiment, the front edges of the same row of blades along the circumferential direction, that is, in the X direction, are arranged alternately in an axial direction, that is, in the Z direction.

[0018] The leading edge of blade 2 in the axial position moves backward relative to the leading edge of blade 1 in the normal position along the axis of the compressor for a certain distance, and the moving distance is 13% of the axial chord length of the blade, wherein the axial chord length is taken as the normal position The width of the blade in the axial direction, and the blade 2 rotates 0.5° around the leading edge point toward the direction of the blade pot, that is, the installation angle defined by the axial Z direction is reduced by 0.5°. In this embodiment, the profile of the blade 2 in the backward position is exactly the same as that of the blade 1 in the normal position.

Embodiment 3

[0020] In this embodiment, the front edges of the same row of blades along the circumferential direction, that is, in the X direction, are arranged alternately in an axial direction, that is, in the Z direction.

[0021] The leading edge of blade 2 moves backward in the axial position relative to the leading edge of blade 1 in the normal position and moves backward for a certain distance along the axial direction of the compressor. The moving distance is 10% of the axial chord length of the blade, and the axial chord length is taken as the normal position The width of the blade in the axial direction, and the blade 2 rotates 3.0° around the leading edge point toward the direction of the blade pot, that is, the installation angle defined by the axial Z direction is reduced by 3.0°. In this embodiment, the profile of the blade 2 in the backward position is exactly the same as that of the blade 1 in the normal position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com