Washing machine

A washing machine and body technology, applied in the field of washing machines, can solve problems such as inconvenient operation, and achieve the effect of improving operability and workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] An embodiment of the present invention will be described in detail below with reference to the accompanying drawings. In addition, it should be pointed out that such embodiments do not limit the scope of the present invention.

[0026] (Example)

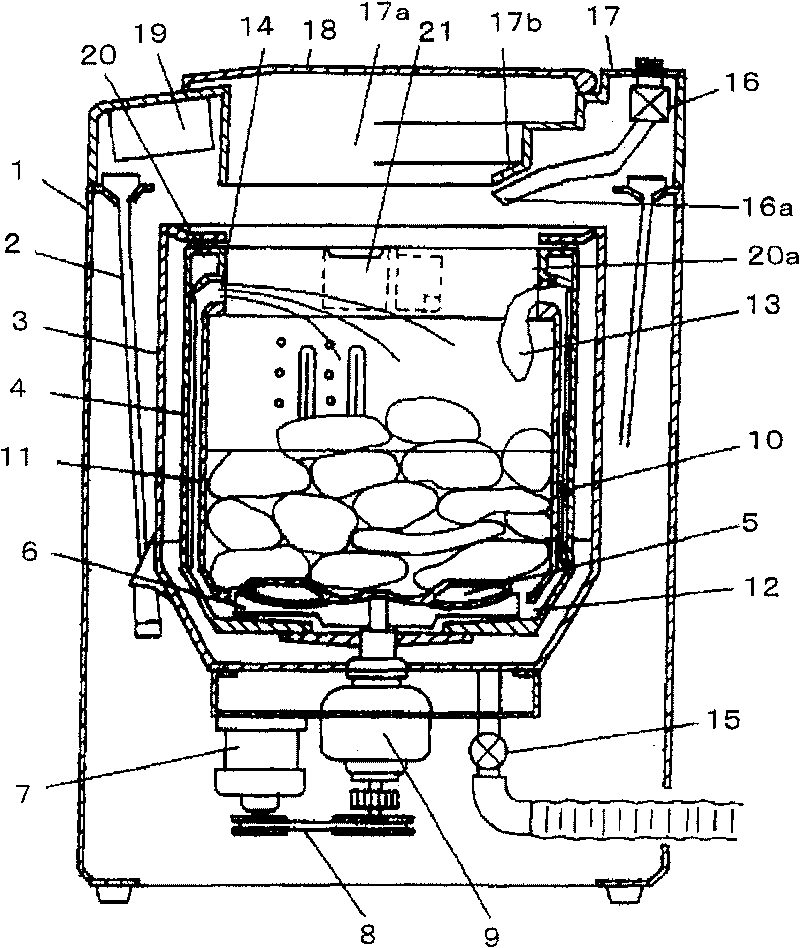

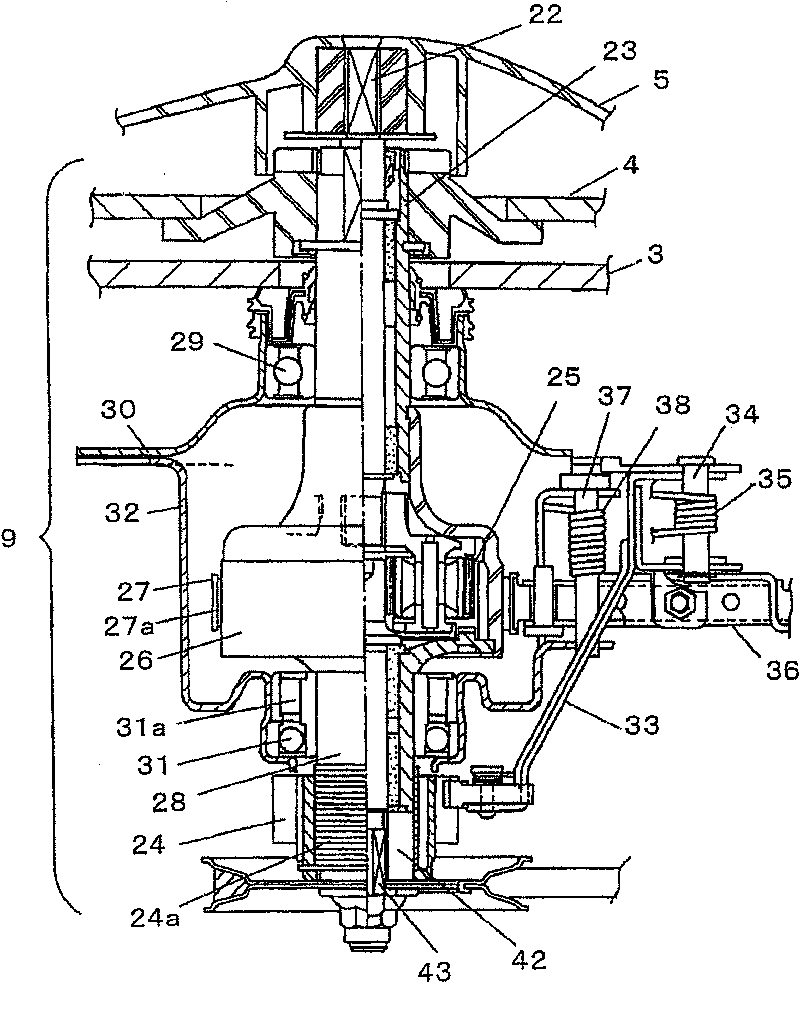

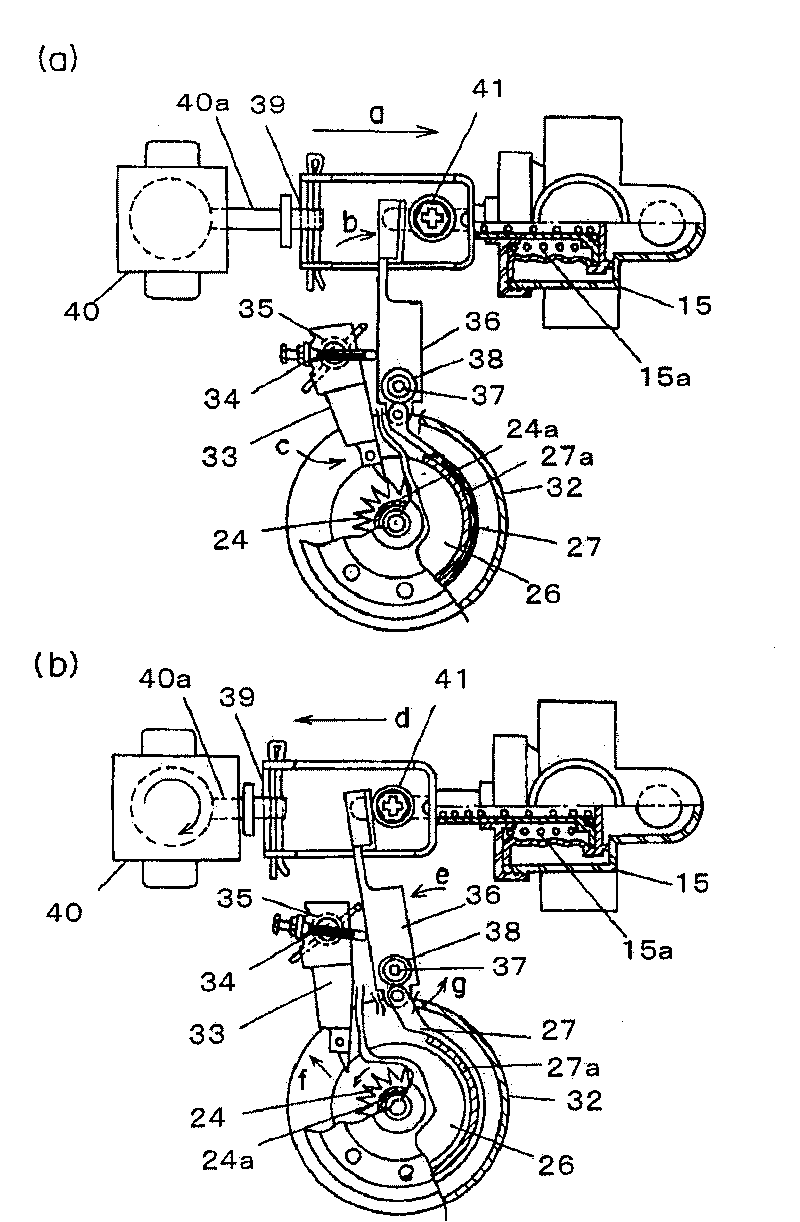

[0027] figure 1 It is a side sectional view of a washing machine in an embodiment of the present invention. As figure 1As shown in , the bucket 3 is suspended in the outer frame 1 of the washing machine through the hanging rod 2, and the inside of the bucket 3 is provided with a washing and dehydrating bucket 4 which can rotate freely. The bottom of the washing and dehydrating bucket 4 is provided with a pulsator 5 which can rotate freely The bottom surface of the pulsator 5 is provided with an integrated lower blade 6. The motor (driver) 7 drives the pulsator 5 or the washing and dehydrating bucket 4 to rotate through the belt 8 and the reduction mechanism 9.

[0028] From the pump chamber 12 around the lower blade 6 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com