Torsion beam type suspension

A technology of torsion beam suspension and torsion beam, which is applied in the direction of suspension, elastic suspension, interconnection system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

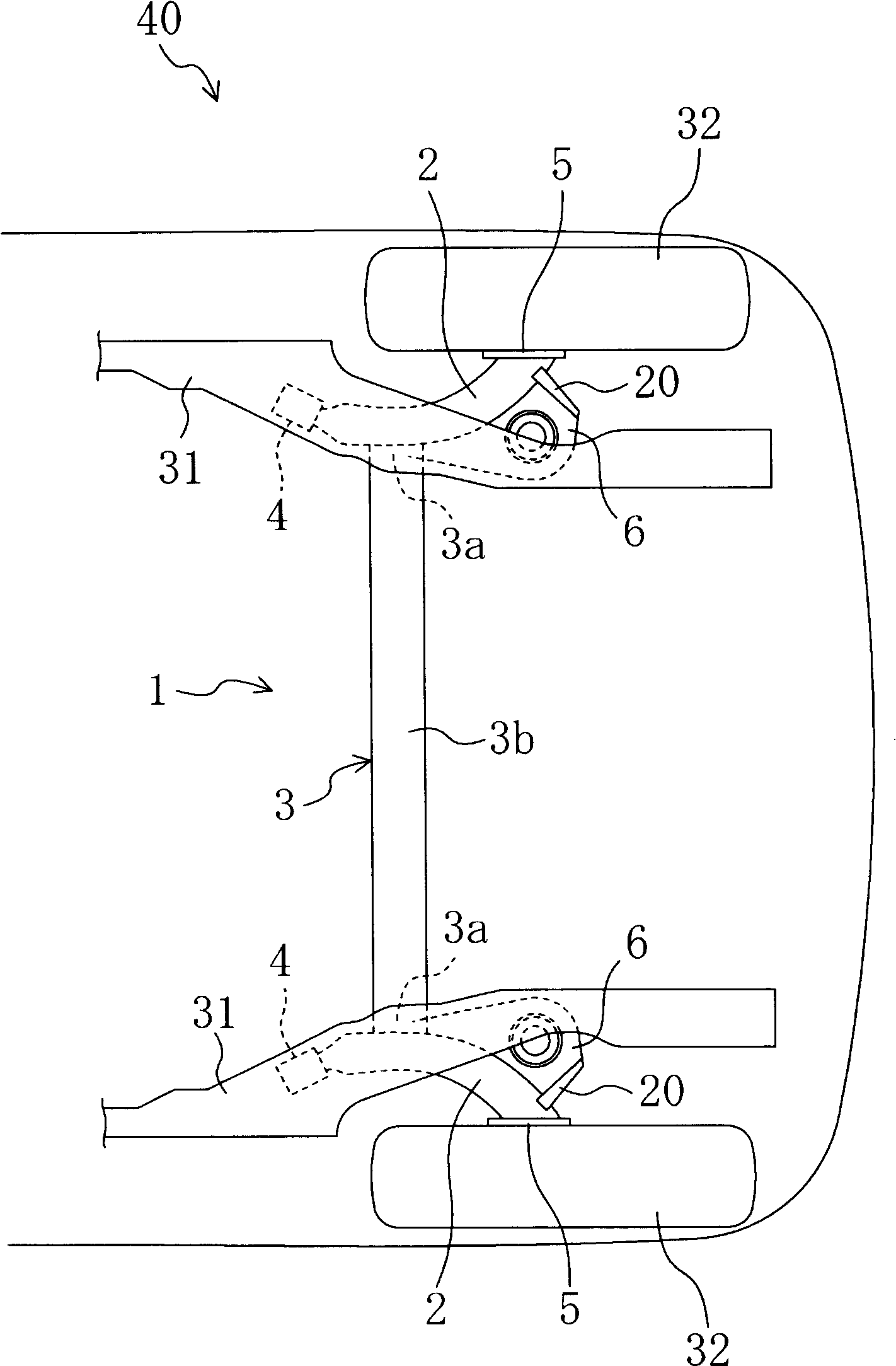

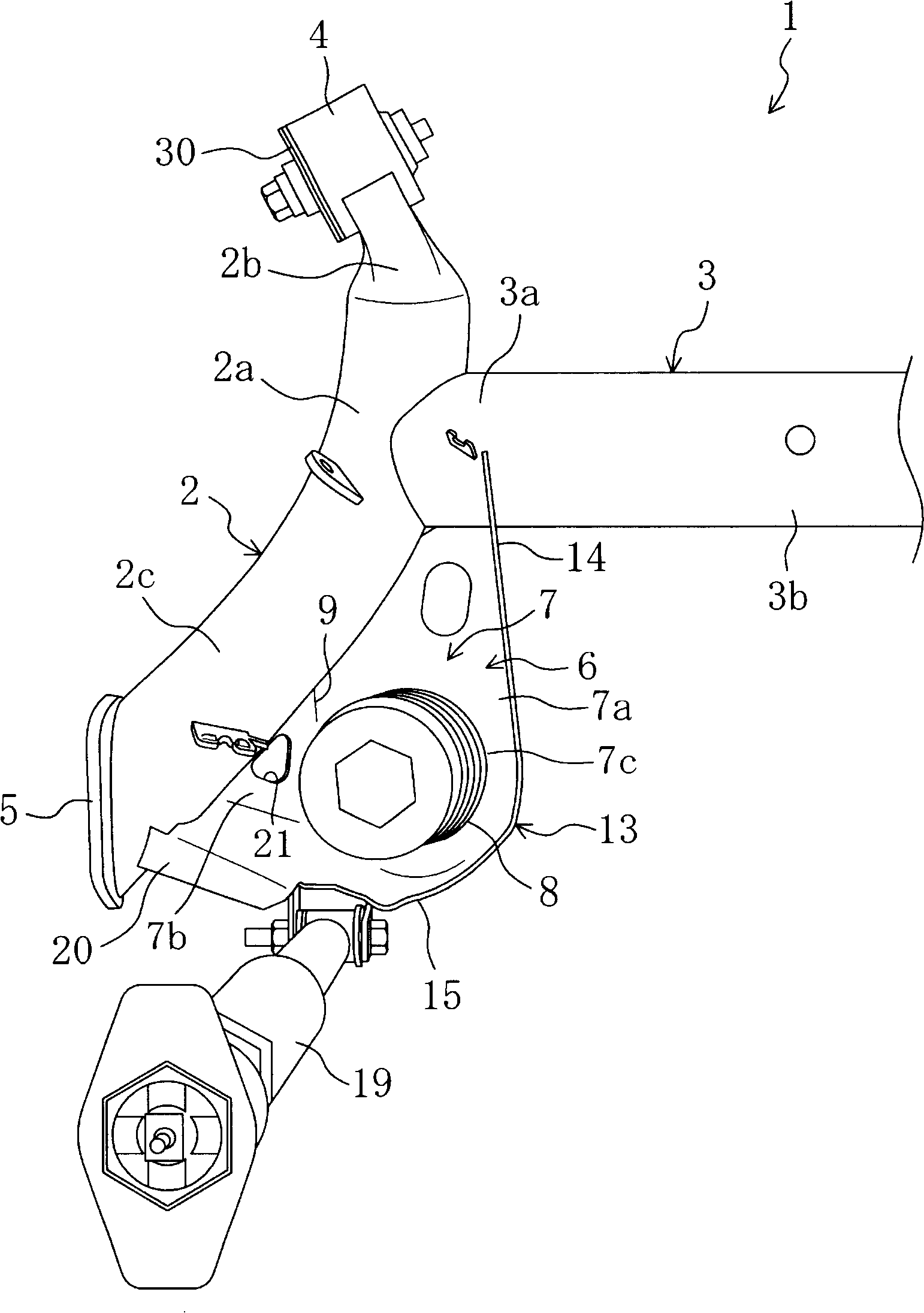

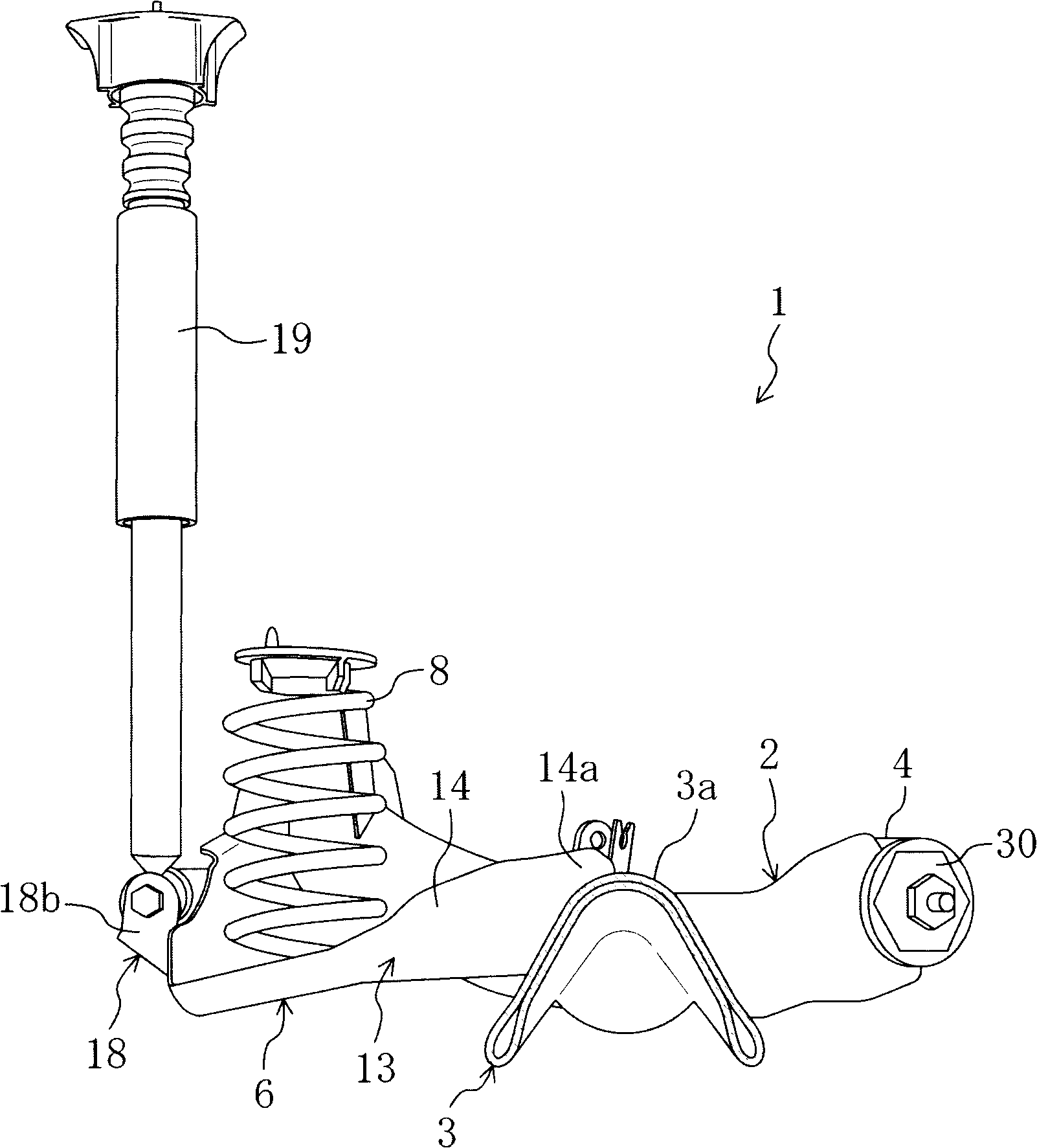

[0039] figure 1 It is a top view showing a vehicle body rear portion 40 having the torsion beam suspension 1 according to the embodiment of the present invention. Figure 2 to Figure 4 These are enlarged views of the left side portion of the torsion beam suspension 1 viewed from above the vehicle, from the inside in the width direction of the vehicle, and from the rear of the vehicle, respectively. The torsion beam suspension 1 includes a pair of left and right suspension trailing arms 2 extending in the vehicle front-rear direction, and a torsion beam 3 extending in the vehicle width direction. A pair of suspension trailing arms 2 are connected to both ends of the torsion beam 3 by welding each longitudinal end 3 a of the torsion beam 3 to the front-rear central portion 2 a of the suspension trailing arm 2 .

[0040]The above-mentioned torsion beam 3 forms a closed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com