External lamina unwinding method and manufacturing method thereof

A manufacturing method and panel unfolding technology, which are applied in the field of outer panel development and outer panel manufacturing, can solve the problems of difficult outer panel processing, not necessarily good processing efficiency, relying on experience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] With reference to the drawings, the embodiments of the outer panel unfolding method and the outer panel manufacturing method of the present invention will be described.

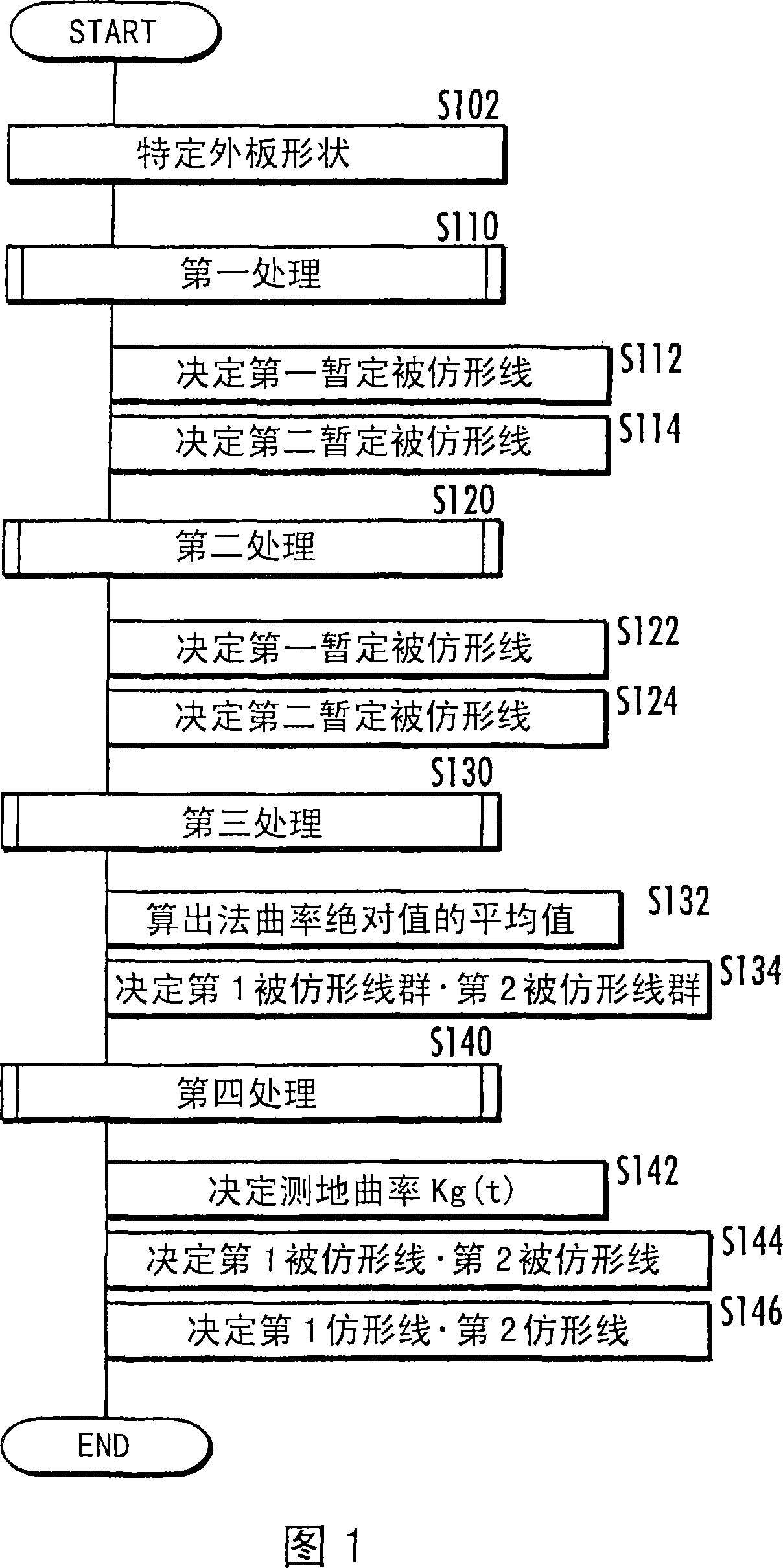

[0027] With reference to Figs. 1-8, the method for unfolding the outer panel of the present invention will be described.

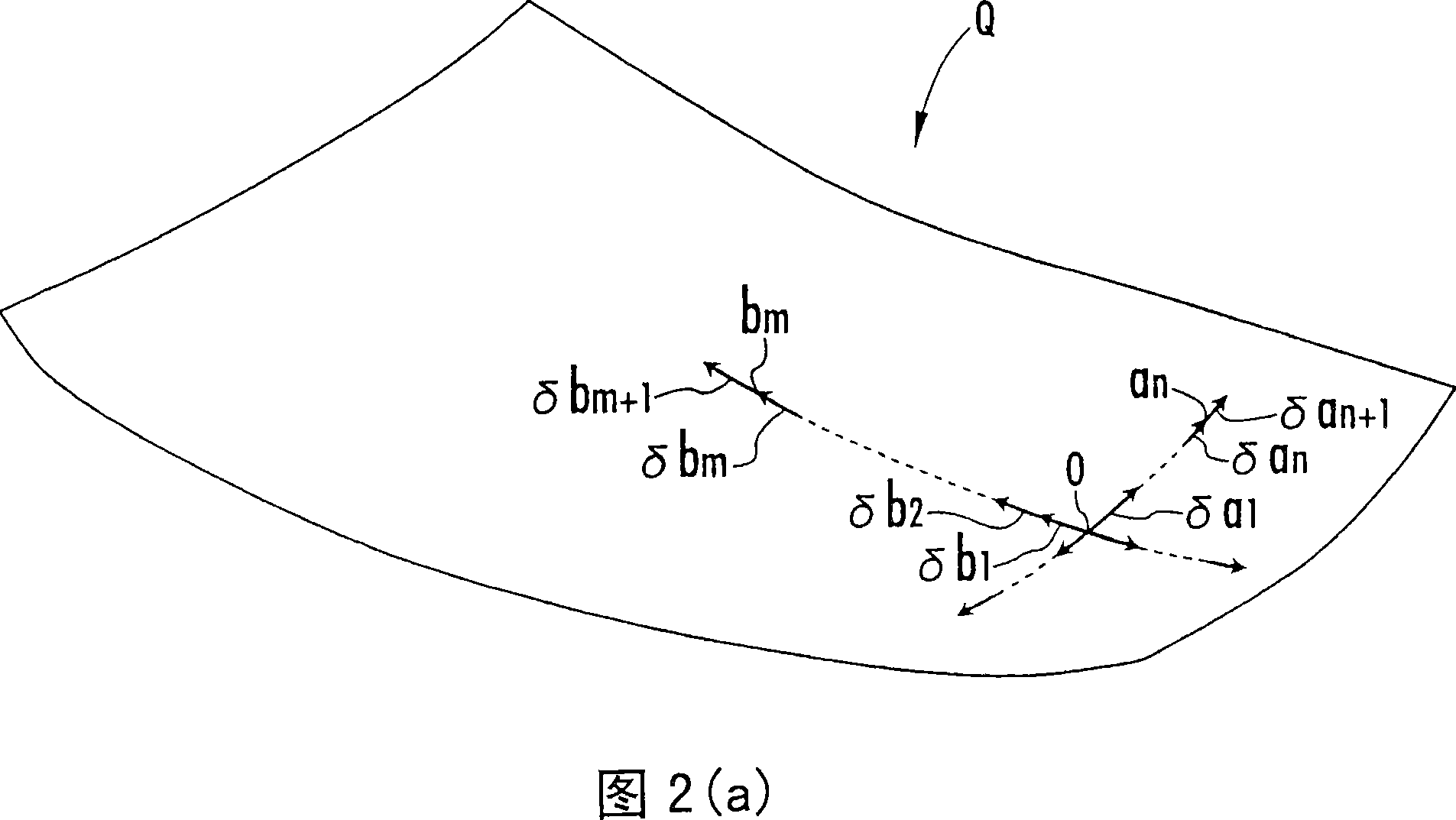

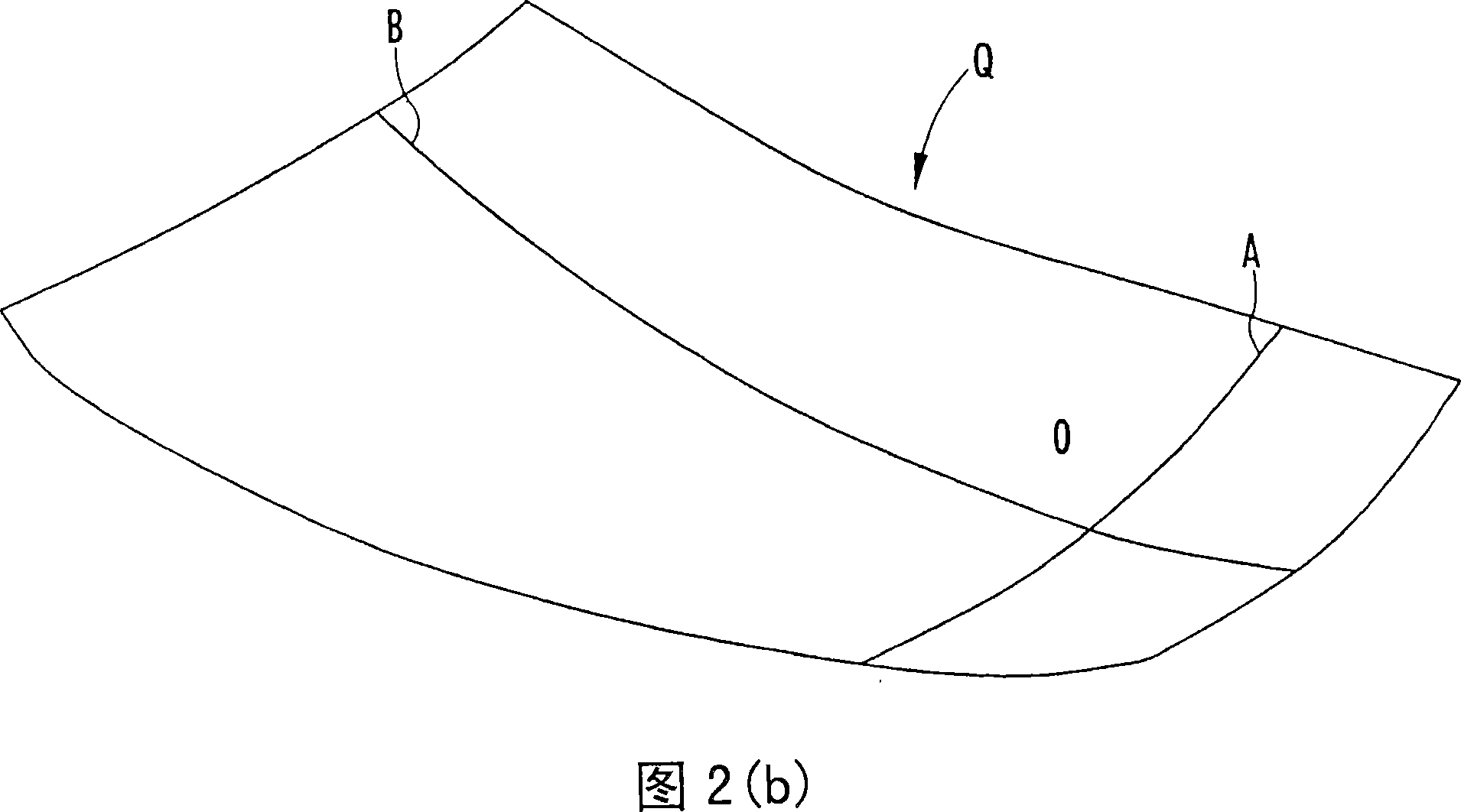

[0028] First, the curved surface represented by the following formula (1) is used to express the outer panel Q shown in Fig. 2 as the target of the outer panel development method, and the shape (predetermined shape) of the outer panel Q is specified (Fig. 1 / S102). The outer panel Q shown in Fig. 2(a) is, for example, a metal outer panel constituting a part of the bow.

[0029] z=Q(x,y) ……(1)

[0030] Next, the "first process" (FIG. 1 / S110) is executed, that is, the process of determining the first tentatively profiled line and the second tentatively profiled line on the outer panel.

[0031] First, the direction when the curvature of the outer plate Q at the starting point is the maxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com