Hinge housing for a door leaf at least by areas made of a thin-walled metal or hollow metal profile

A door leaf and thin-walled technology is applied in the field of hinge shells used for door leaves at least partially composed of thin-walled metal or metal hollow profiles, and can solve problems such as damage to the firm fit and reliable fixation of the hinge shell, and labor-intensive problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

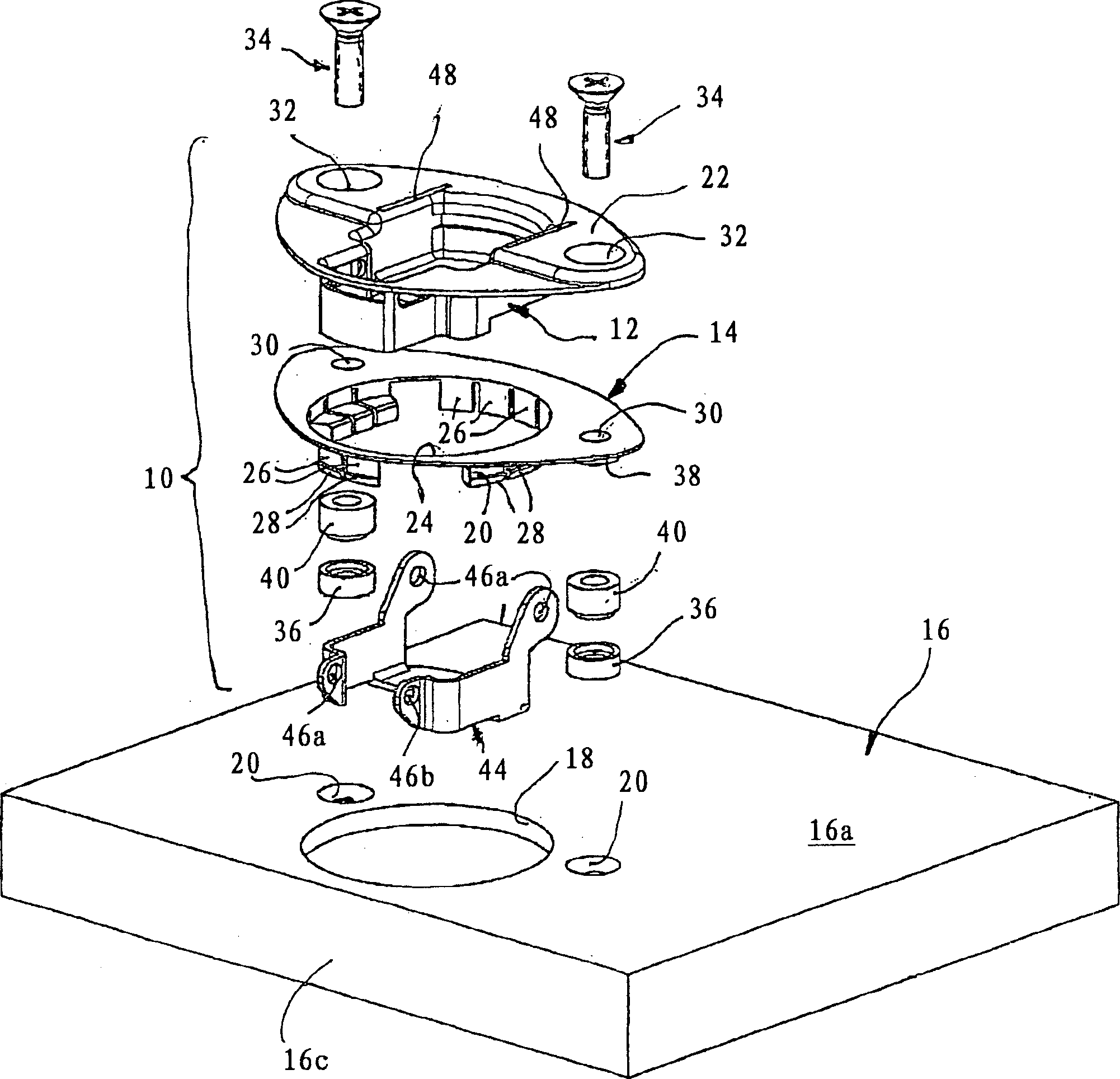

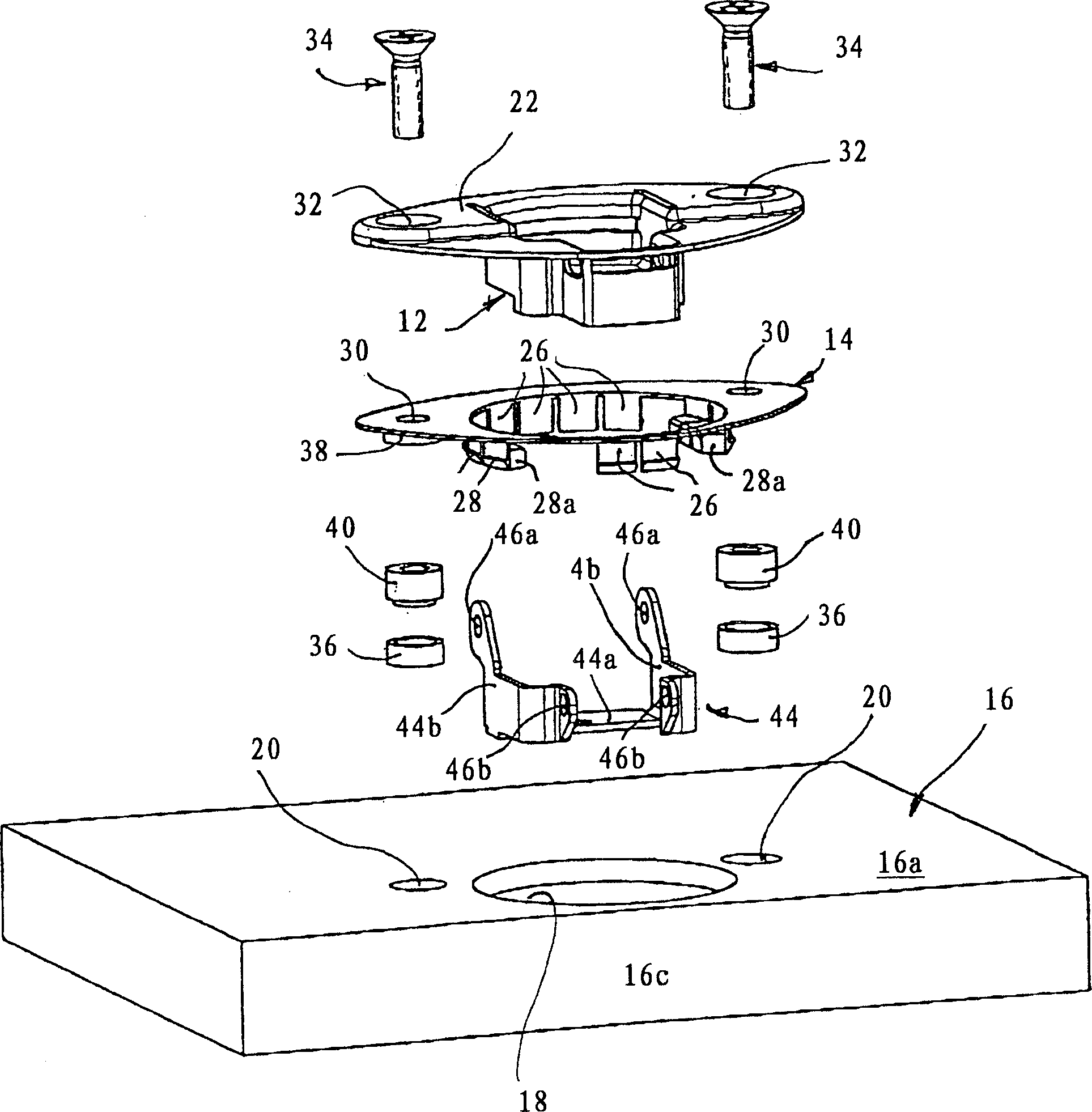

[0019] The hinge housing shown in the figure generally indicated by 10 is made of a metal, especially combined below figure 2 with 3 The cup 12 and a plastic backing 14 are further described in detail. The hinge housing 10 forms the leaf stop of an otherwise not shown hinge, in particular a four-joint hinge, by means of which the sheet metal door leaf 16 is articulated pivotably on the cone.

[0020]The hinge housing 10 is intended to be embedded and fixed in the double-walled edge region of the door leaf 16, wherein the inner wall of the door body when the door leaf is closed is designated by 16a, and the outer wall is designated by 16b, which are held by the end wall 16c constituting the lateral boundary of the door leaf. The smaller prescribed distance results in a relatively flat cavity between walls 16a and 16b.

[0021] In order to fix the hinge housing 10, on the wall 16a, especially on the figure 2 with 3 punched or drilled through-holes as shown in , that is to sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com