Ink transfer device for a printing press

一种转移装置、印刷机的技术,应用在印刷机、印刷机械的通用零件、印刷等方向,能够解决印刷质量振动带限制等问题,达到减小滚筒振动趋势、减小滚筒振动、高印刷质量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In the following text, reference figure 1 -7 The present invention will be described in more detail.

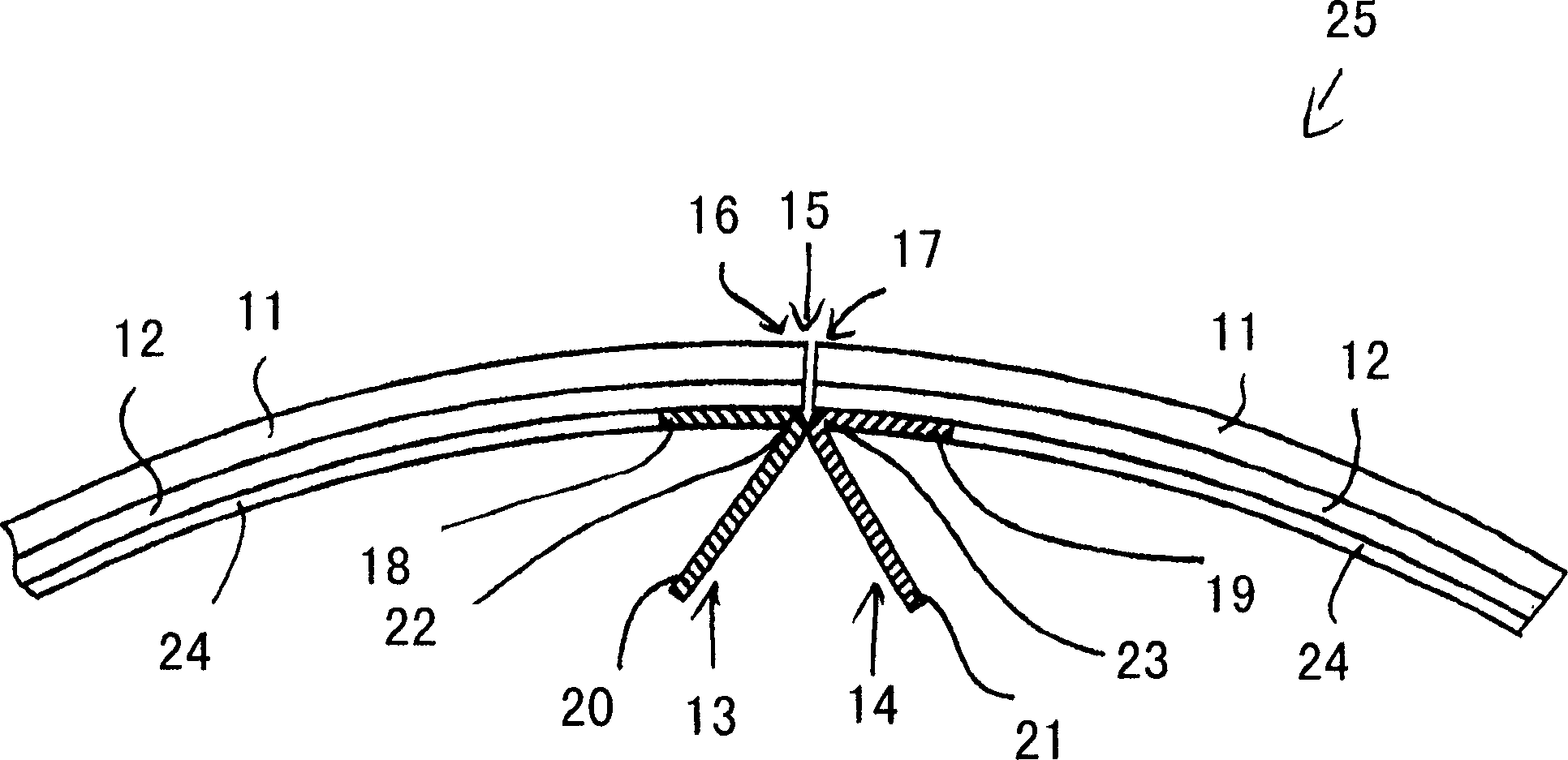

[0020] figure 1 showing details of an ink transfer device according to the invention as it is clamped on a rubber-covered cylinder (not shown), figure 1 The ink transfer device includes a rubber blanket 11 and a bearing member 12 corresponding to the rubber blanket 11 . rubber sheet 11 and carrier element 12 in the figure 1 Exemplary embodiments are designed as separate subassemblies.

[0021] The rubber blanket 11 is formed in a plurality of layers. The carrier element 12 can be designed as a metal carrier, as a woven fabric carrier or as a fiber-reinforced plastic carrier. according to figure 1 , in the clamped state, the carrier element 12 is positioned radially on the inside and the rubber blanket 11 is positioned radially on the outside. The carrier element 12 serves to hold the rubber blanket 11 . It should be pointed out that the carrier element 12 can a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com