Method and apparatus for treating a re-imageble printing plate

A printing plate, imaging technology used in the field of processing re-imageable printing plates and devices, which can solve the problems of time-consuming, production downtime, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Features corresponding to or identical to each other in the figures are provided with the same reference numerals.

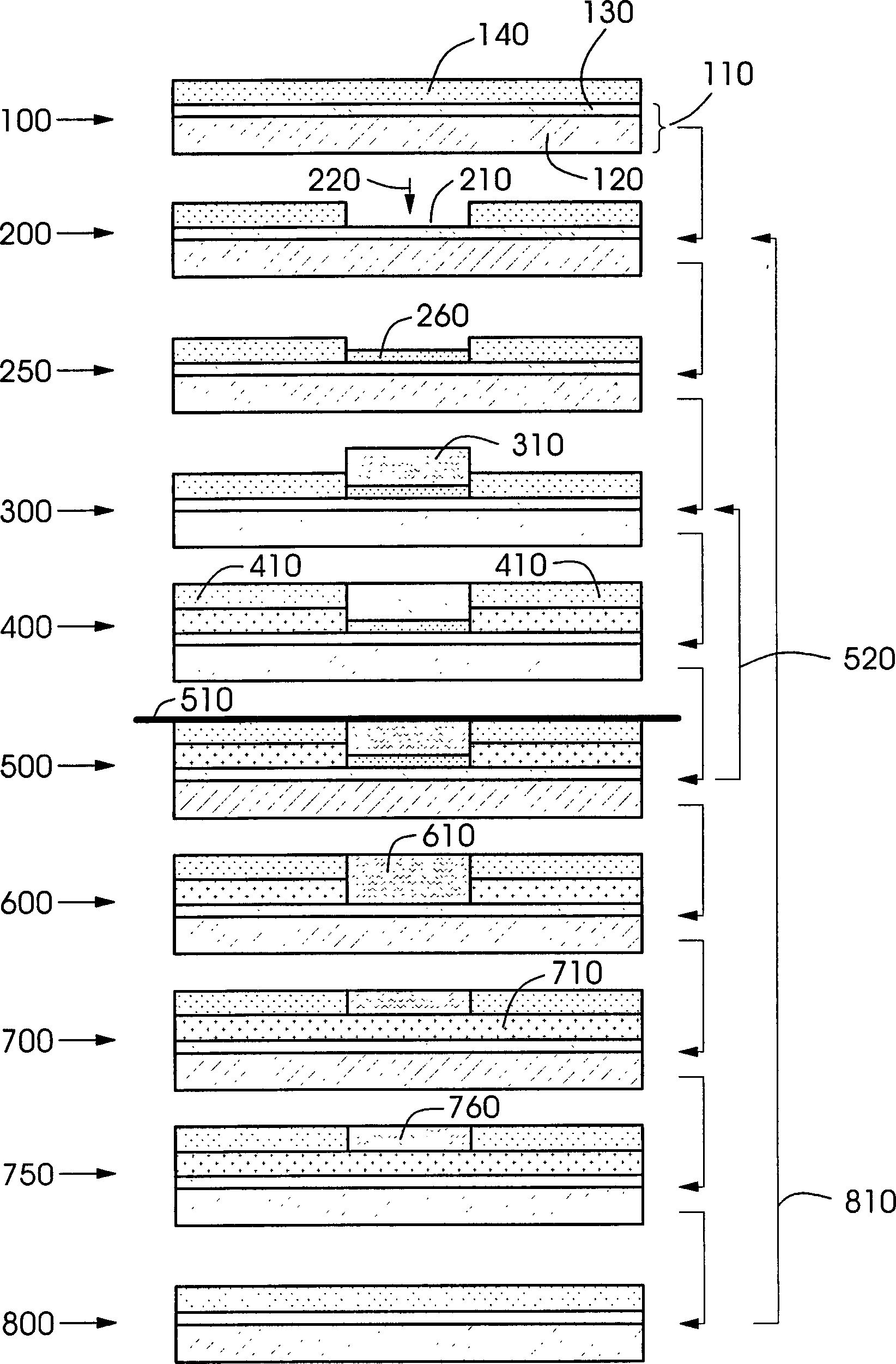

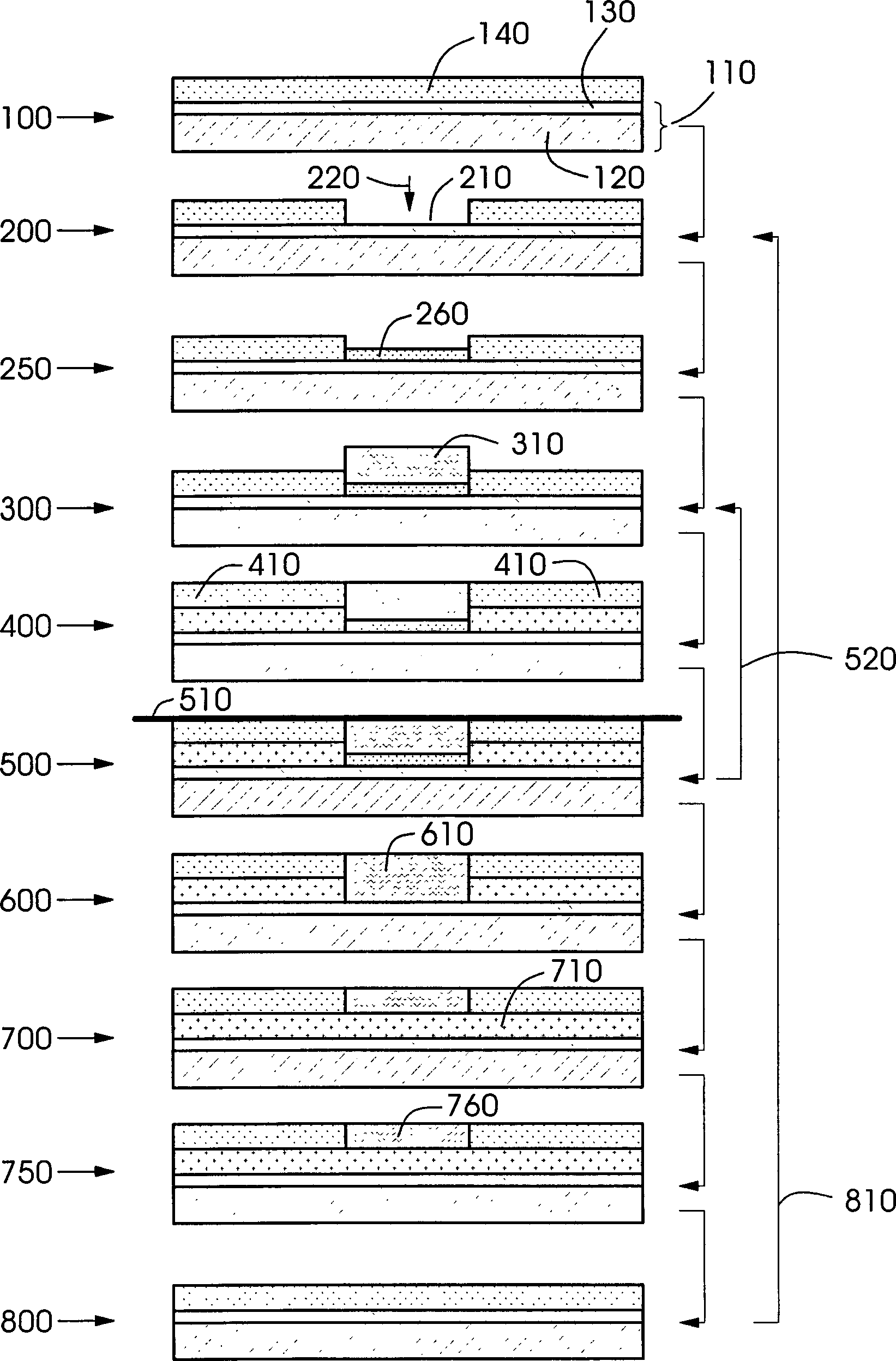

[0028] figure 1 The flow of an embodiment of the method according to the invention is shown schematically. In a method step 100 (preparation), a titanium printing plate 110 is prepared, which has a support 120 made of titanium (Ti) with a support made of titanium dioxide (TiO 2 ) (alternatively composed of TiOx, ZrO 2 , Al 2 O 3 , other metal oxides or high-quality steel), the titanium printing plate also has a coating with a layer 140 of amphiphilic molecules on this surface 130 . By coating the amphiphilic molecules, the surface of the printing plate 110 has a defined uniform hydrophobicity.

[0029] Before the first printing, when the printing plate 110 is prepared for the first time, the printing plate can be pre-cleaned with acetone and cleaned with UV rays in a first step and activated (for example: using a strength of 45 mW / cm 2and a xenon ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com