Liftable deep well false bottom system

A technology for deep wells and mooring devices, which is applied to ship components, measuring devices, instruments, etc., and can solve problems such as

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

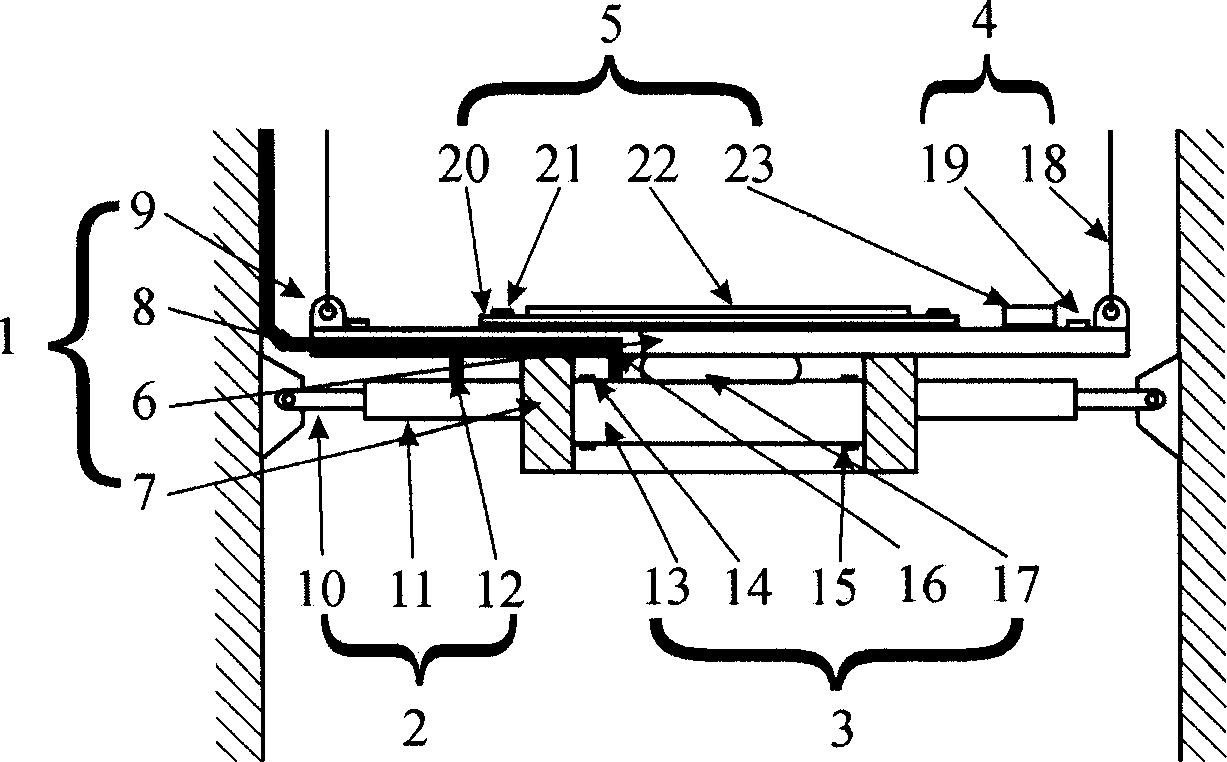

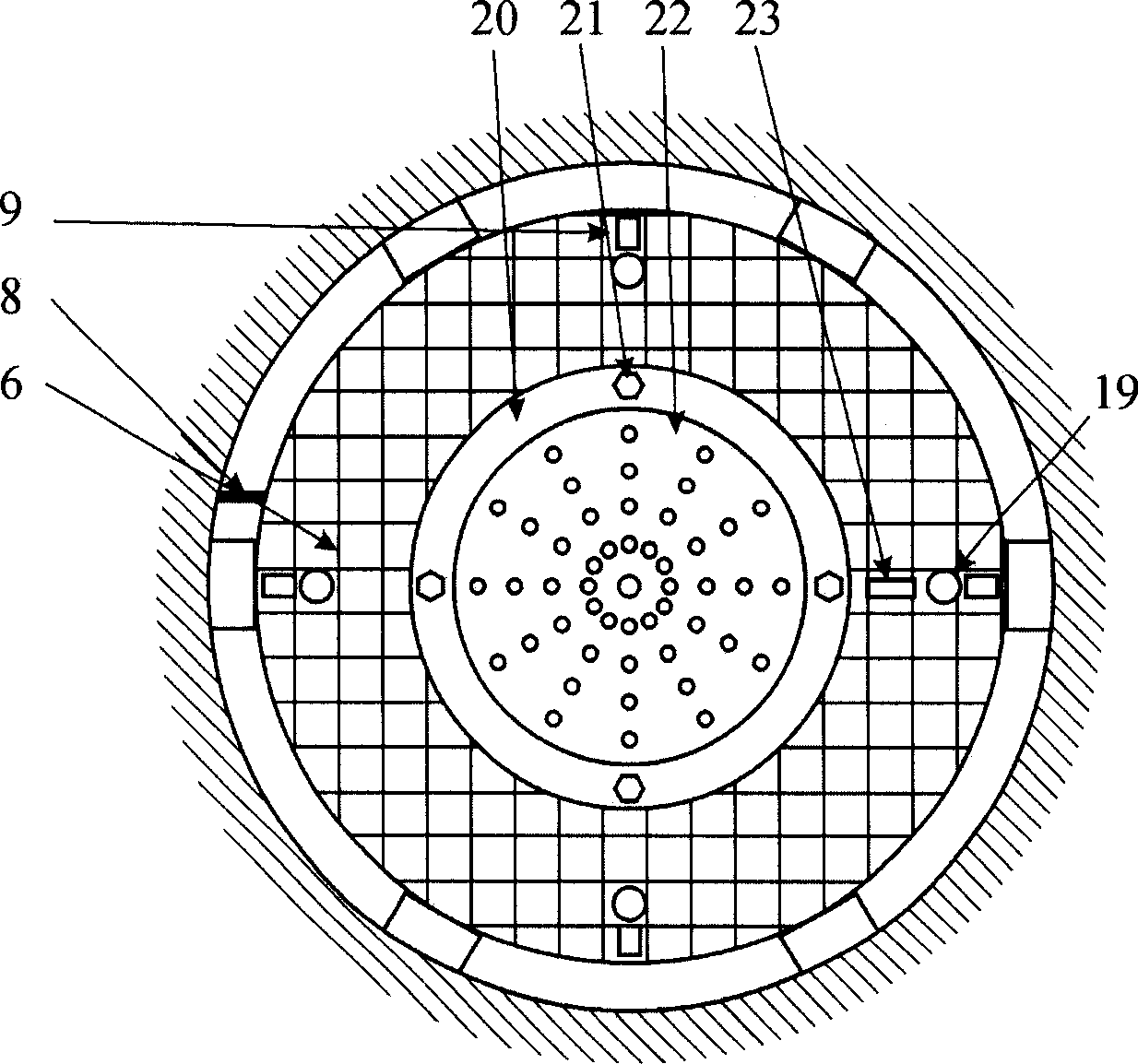

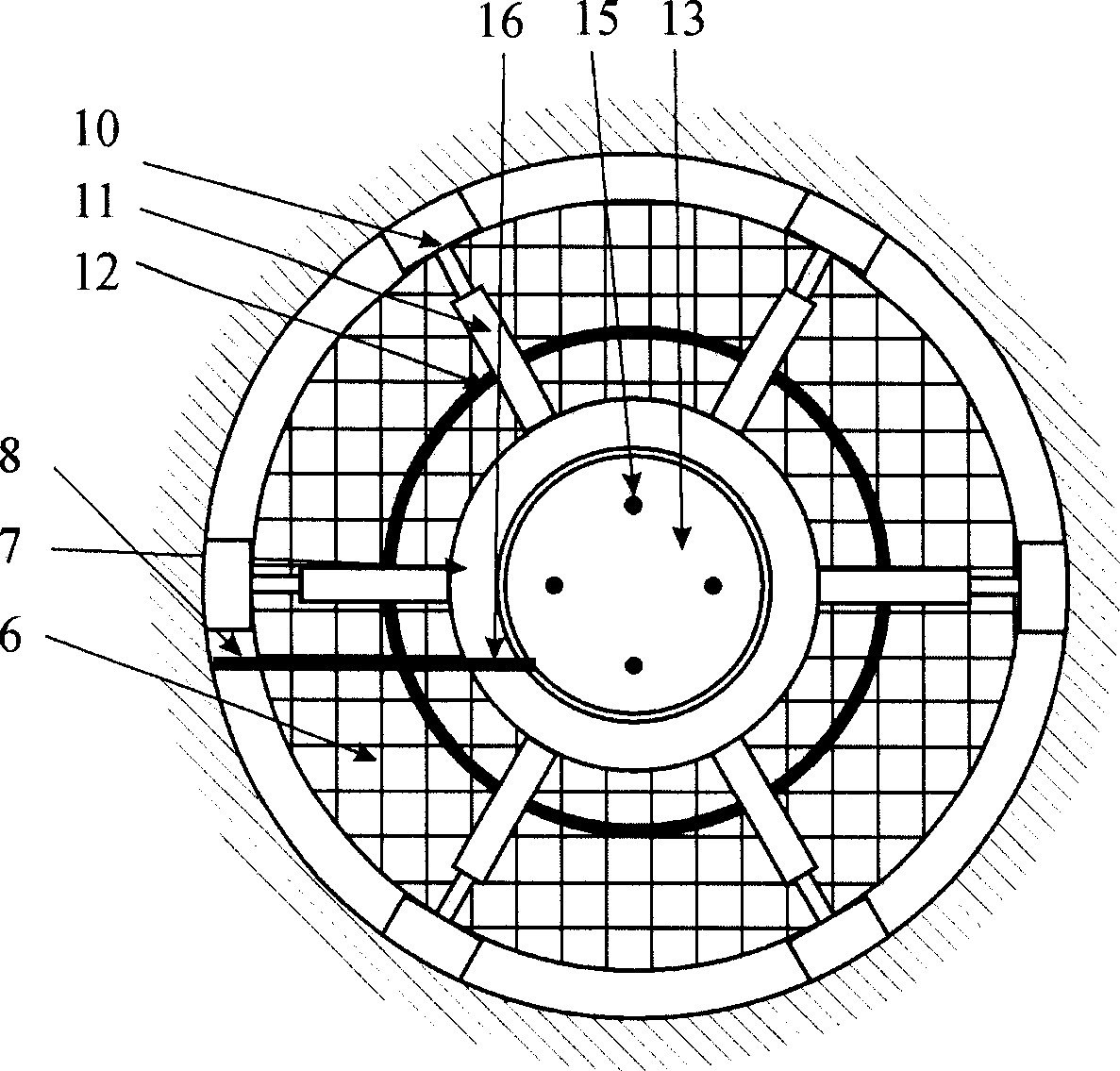

[0018] Such as Figure 1-3 As shown, the present invention includes: a deep well false bottom structure main body 1, a position locking device 2, a buoyancy adjusting device 3, a lifting device 4, and a mooring device 5 for experiments. The main body of the deep well false bottom structure 1 serves as the main frame of the entire deep well false bottom structure. A total of six sets of position locking devices 2 are arranged around the bottom of the deep well false bottom structure main body 1, and the buoyancy adjustment device 3 is arranged at the center of the bottom of the deep well false bottom structure main body 1. A mooring device 5 for experiments is installed in the middle of the upper surface of the main frame of the false bottom of the deep well, and a lifting device 4 is installed around it.

[0019] The deep well false bottom structure main body 1 includes: vertical and horizontal beam system 6 , circular frame 7 , compressed air supply pipeline 8 , and lifting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com