Driving circuit for nuclear power station reactor control stick

A technology for nuclear power plant reactors and drive circuits, applied in the power supply field, can solve problems such as large current ripple, poor follow-up characteristics, and complex circuits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Coil current control method:

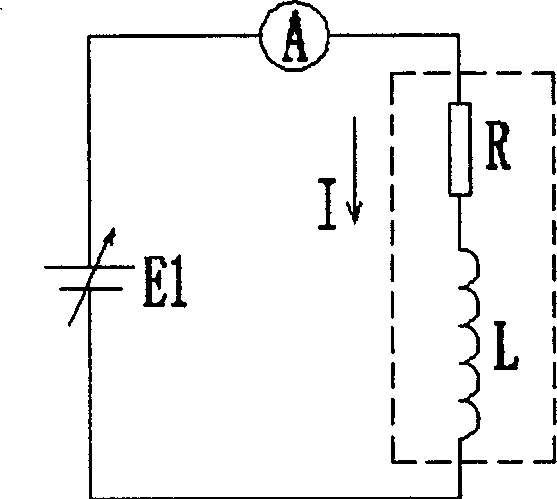

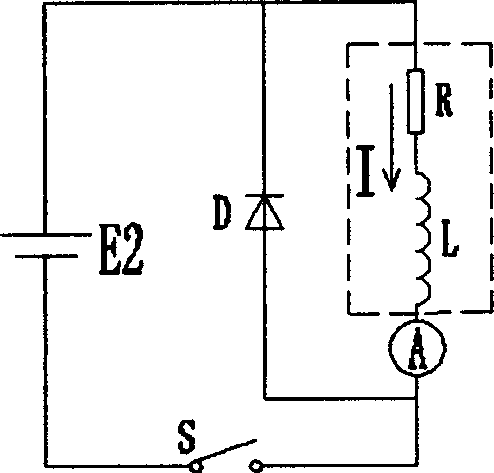

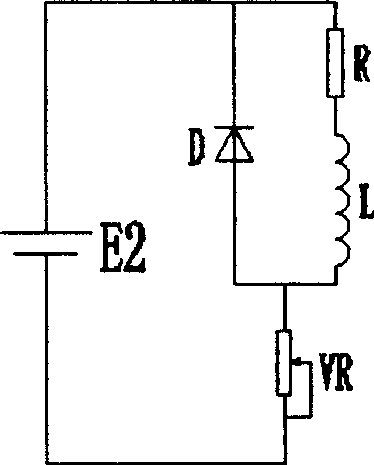

[0018] The circuit symbol of the rod control coil is represented by the series connection of resistance R and inductance L. Figure 1-a It is a coil voltage control method and a direct application of Ohm's law. Changing the output voltage of the controllable voltage source E1 changes the current in the coil RL. Figure 1-b E2 in E2 is a fixed voltage source, through the high-speed on-off control of the electronic switch S, the current in the coil RL can also be controlled. Figure 1-c The current in the coil can also be changed by changing the resistance value of the variable resistor VR connected in series.

[0019] Figure 1-c The additional loss of the method is too large and difficult to control, which is obviously not advisable. Figure 1-a The circuit looks simple, but in fact it is more Figure 1-b Much more complicated. Because it is very complicated to construct a controllable voltage source E1. Figure 1-b The fixed voltage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com