Sintering automatic distributing method

A technology of automatic material distribution and material distribution, which is applied in the direction of furnaces, lighting and heating equipment, furnace components, etc., can solve the problems of production data collection and detection lag, randomness, etc., and achieve good practicability and reliability, structure and control principle Simple, Stable Positive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

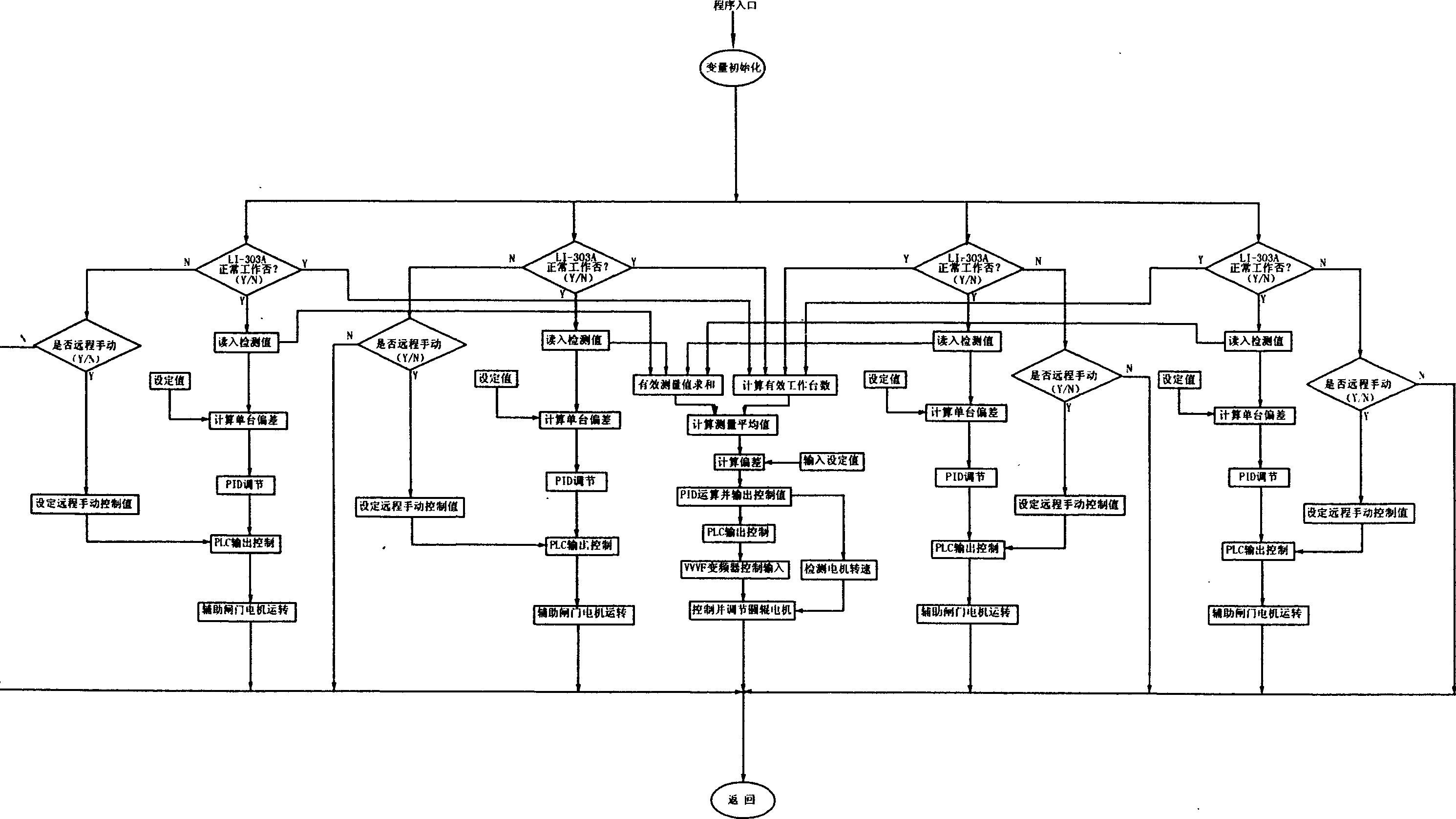

[0018] see figure 1 and figure 2 , a sintering automatic distributing method, the control components mainly include: nine-roll distributing device 7, VVVF frequency converter, round roller motor, micro-motion motor, PLC programmable controller, PID proportional, integral, differential controller, computer and radar Material level gauge 11.

[0019] The automatic material distributing device of the sintering machine is composed of radar level gauge 11, the model of radar level gauge 11 is VEGAPULS68, material distributing equipment and control system. The structure of the device is as follows: figure 1 As shown; the control system is divided into 6 speed automatic control systems of round roller feeders and auxiliary gate opening automatic control systems,

[0020] Since the inclination angle of the sintered mixture accumulation is fixed, the measured material height of the mixture accumulation shows a linear change trend. The changing trend of the amount of mixed material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com