Process for the detection of vibrations of a roll stand

A roll machine and rack technology, which is applied in the field of detecting the vibration of roll racks, and can solve problems such as inability to distinguish racks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

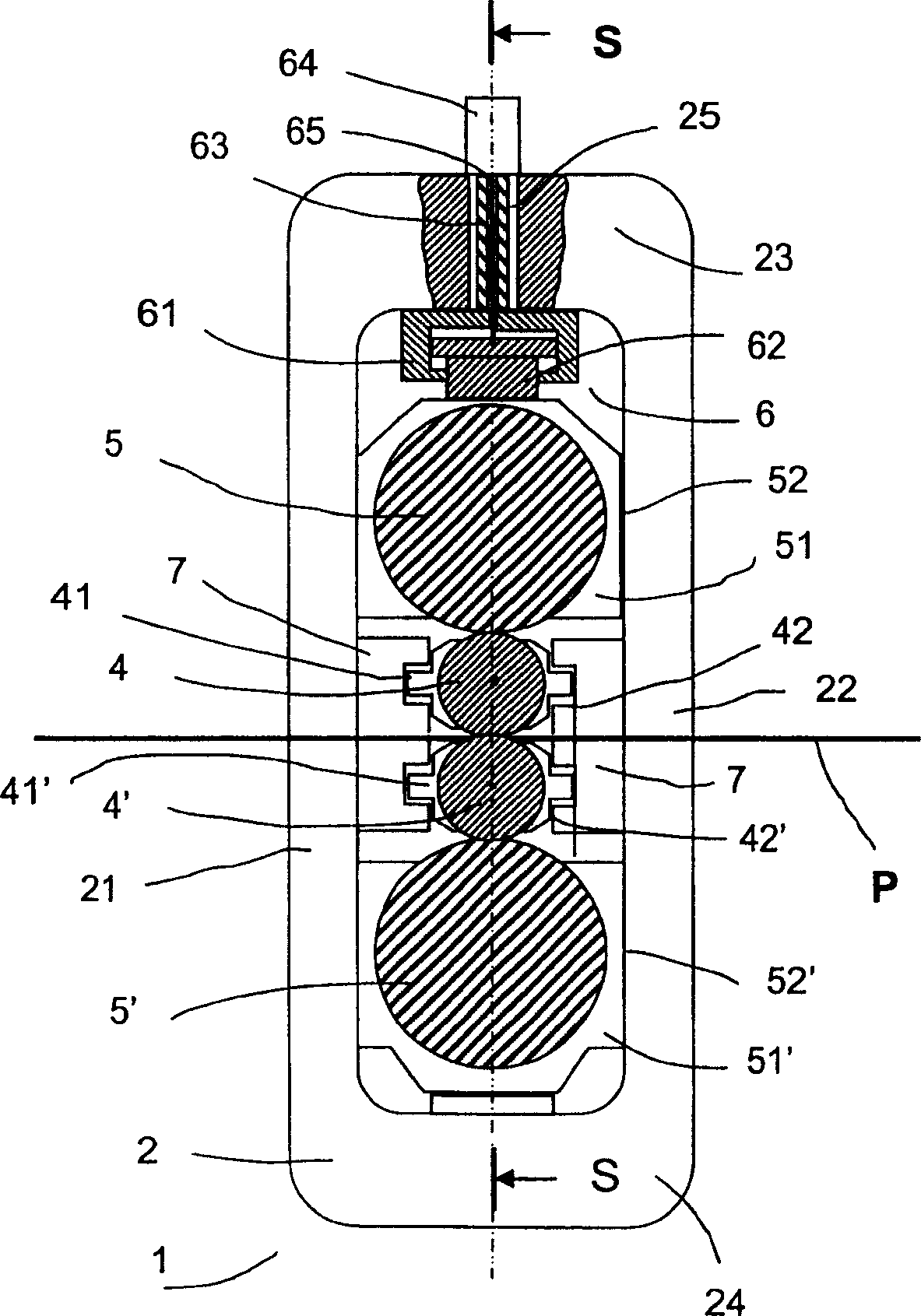

[0033] Such as figure 1 and figure 2 As shown, the roll stand 1 itself is a four-roll roll stand known to those skilled in the art, and it includes two support columns (support column) 2 and 2'. Support frames 2 and 2' are separated and connected by cross beams 3, 3' between which are arranged a set of superimposed rollers with parallel axes positioned substantially in line with the rolling mill. In the same adjustment plane S that is perpendicular to the moving direction of the material P.

[0034] Each shelf 2, 2' has a closed shape to form a ring and each shelf comprises two upright pillars 21, 22 (21', 22') and two horizontal parts 23, 24 (23', 24') .

[0035] The set of stacked rolls includes two work rolls 4, 4' and two backing rolls 5, 5', the rolling stock P passes through the middle of the work rolls 4, 4', and the work rolls rest against the backing rolls. On the roller 5, 5'.

[0036] Incidentally, it can be noted that besides the four-high roll stand, there are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com