Liquid asphalt proportioning system flow and device

A batching system and liquid asphalt technology, applied in mixer parts, clay preparation devices, dissolving and other directions, can solve problems such as pipeline blockage, asphalt cannot be fed, verification and production processes cannot be carried out at the same time, and achieve the elimination of blockage and production process. Unobstructed and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

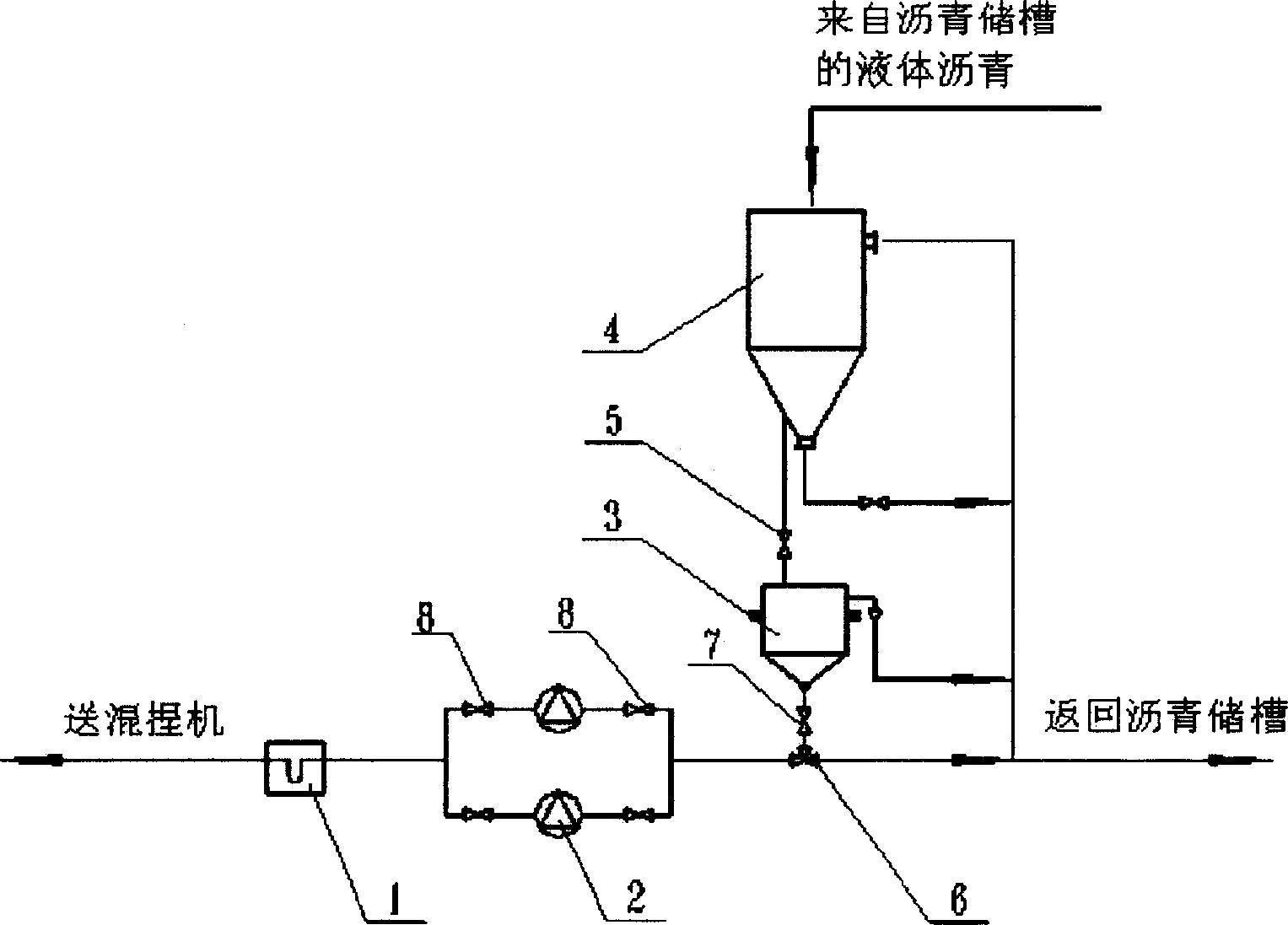

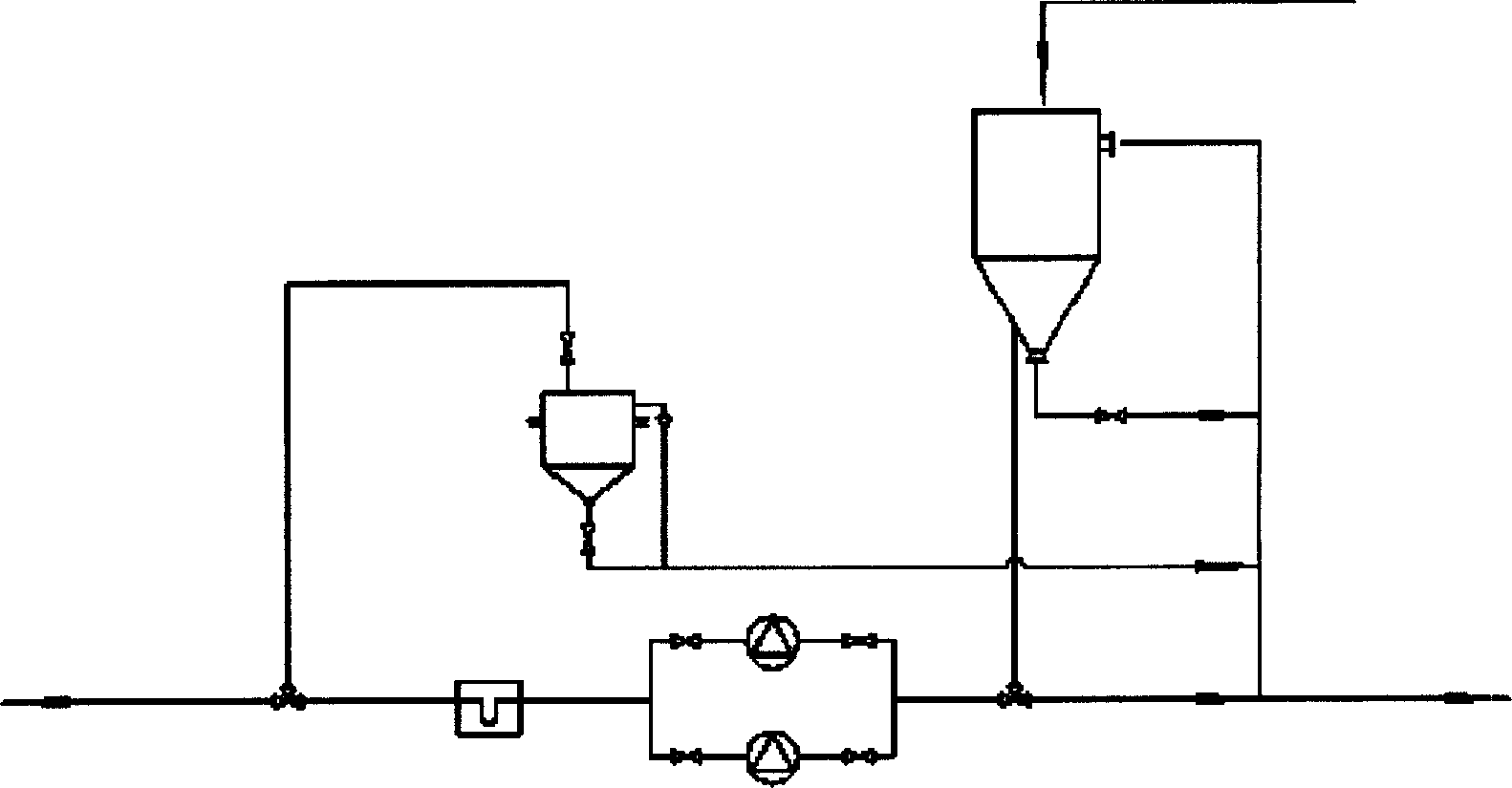

[0010] Embodiments of the present invention: according to the conveying flow and pressure requirements of asphalt, design the elevated tank 4 and the calibration tank 3, select the specifications of the asphalt pump, various valves and pipelines, and then connect them in the following order: the elevated tank 4 The outlet is connected to one end of the two-way valve 5, between the other end of the two-way valve 5 and the inlet of the calibration tank 3, the outlet of the calibration tank 3 is connected to one end of the two-way valve 7, and the other end of the two-way valve 7 is connected to the One end of the three-way valve 6 is connected; the inlet and outlet of the two asphalt pumps 2 are connected to the two-way valve 8 and then connected in parallel with the three-way valve 6 and the mass flow meter 1, and the mass flow meter 1 is connected to the pipeline of the kneader; the high-level tank 4 The overflow port, the lower discharge port, the overflow port of the calibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com