Fuse box

A technology of fuses and fuse boxes, applied in the direction of electrical components, circuits, emergency protection devices, etc., can solve the problems of tongue terminal part 55 damage, poor insertion operation efficiency, breakage, etc., to prevent deformation or breakage, support Well-balanced, overall height-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Preferred embodiments of the fuse of the present invention will be described in detail below with reference to the accompanying drawings.

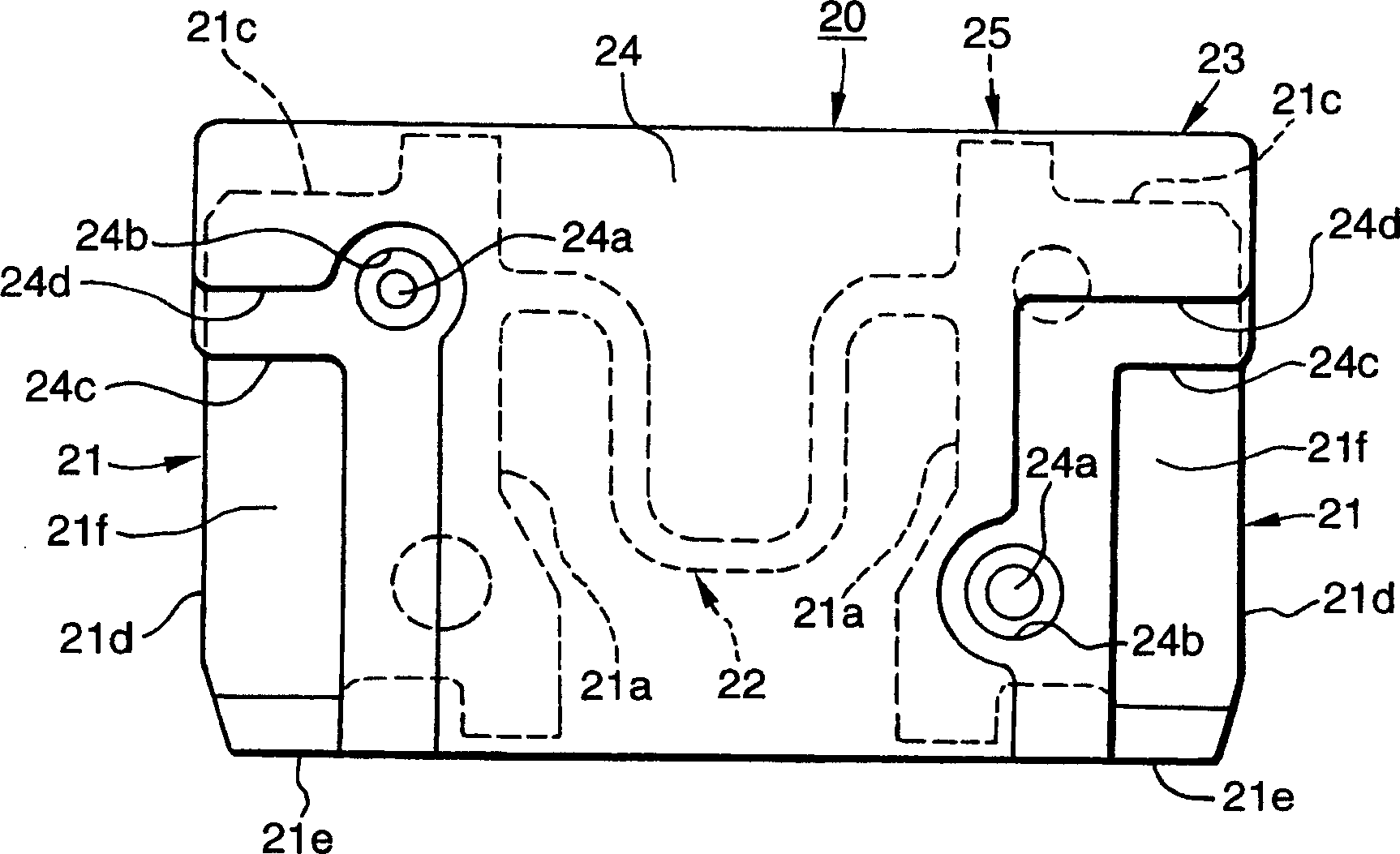

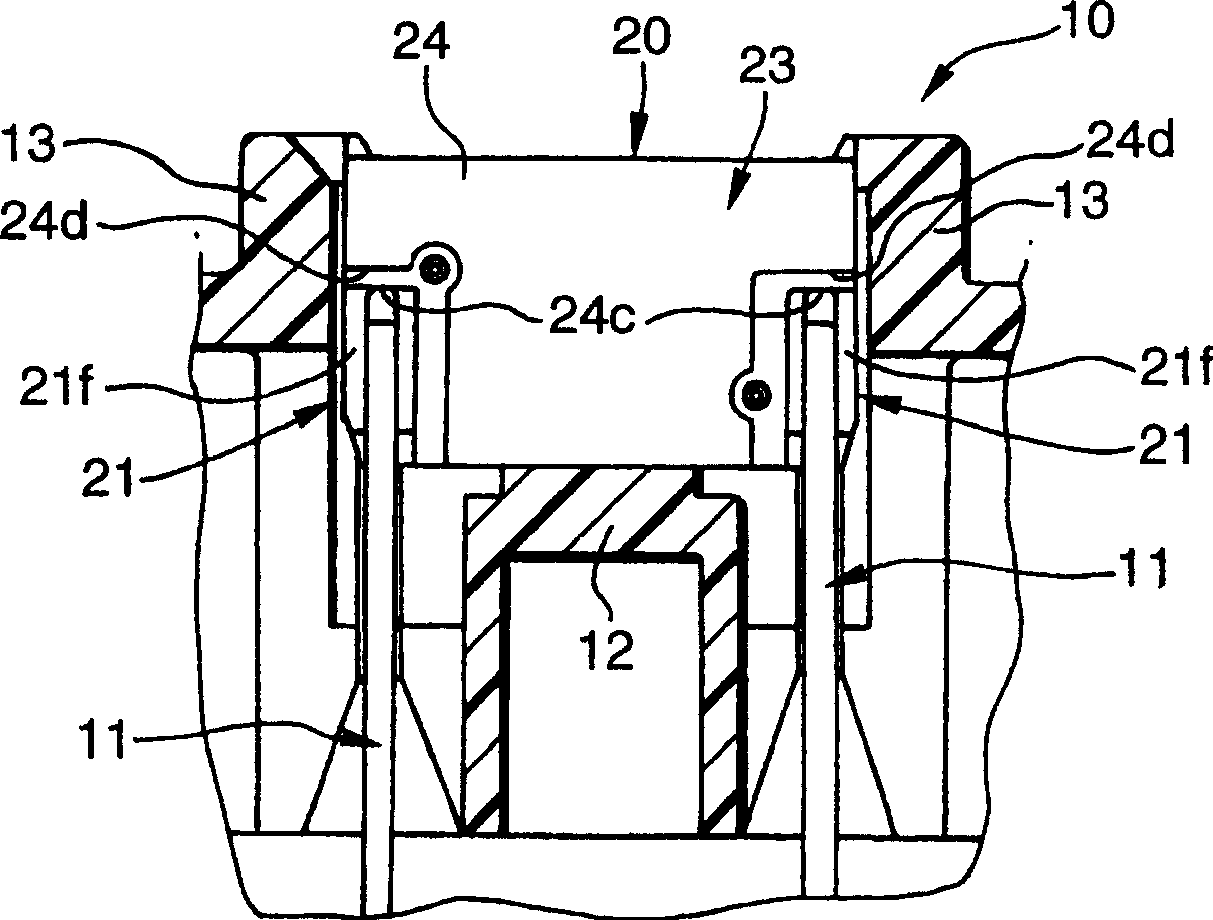

[0040] figure 1 is an exploded perspective view showing a first embodiment of the fuse of the present invention, figure 2 Yes figure 1 front view of the fuse in the image 3 and 4 are shown respectively figure 1 Front and side views of the state in which the fuse in is installed in the fuse mounting section.

[0041] The fuse 20 in the first embodiment is a chip fuse in which a fuse element 25 is provided in an insulating case 23, and the fuse element 25 has a fusible part 22 arranged in a pair of parallel Between the flat terminal parts 21 and 21.

[0042] Each flat terminal portion 21 has a substantially rectangular shape, and a fusible portion 22 having a predetermined cross-sectional area extends between opposing inner side edges 21 a and 21 a of the flat terminal portions 21 and 21 .

[0043] The insulating case 23 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com