Sealing pad structure of drum washing machine

A technology for drum washing machines and sealing pads, which can be applied to other washing machines, washing devices, textiles and papermaking, etc. It can solve the problems of accumulation near the end, inconvenient use, incomplete dehydration, etc., so as to improve reliability and facilitate use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

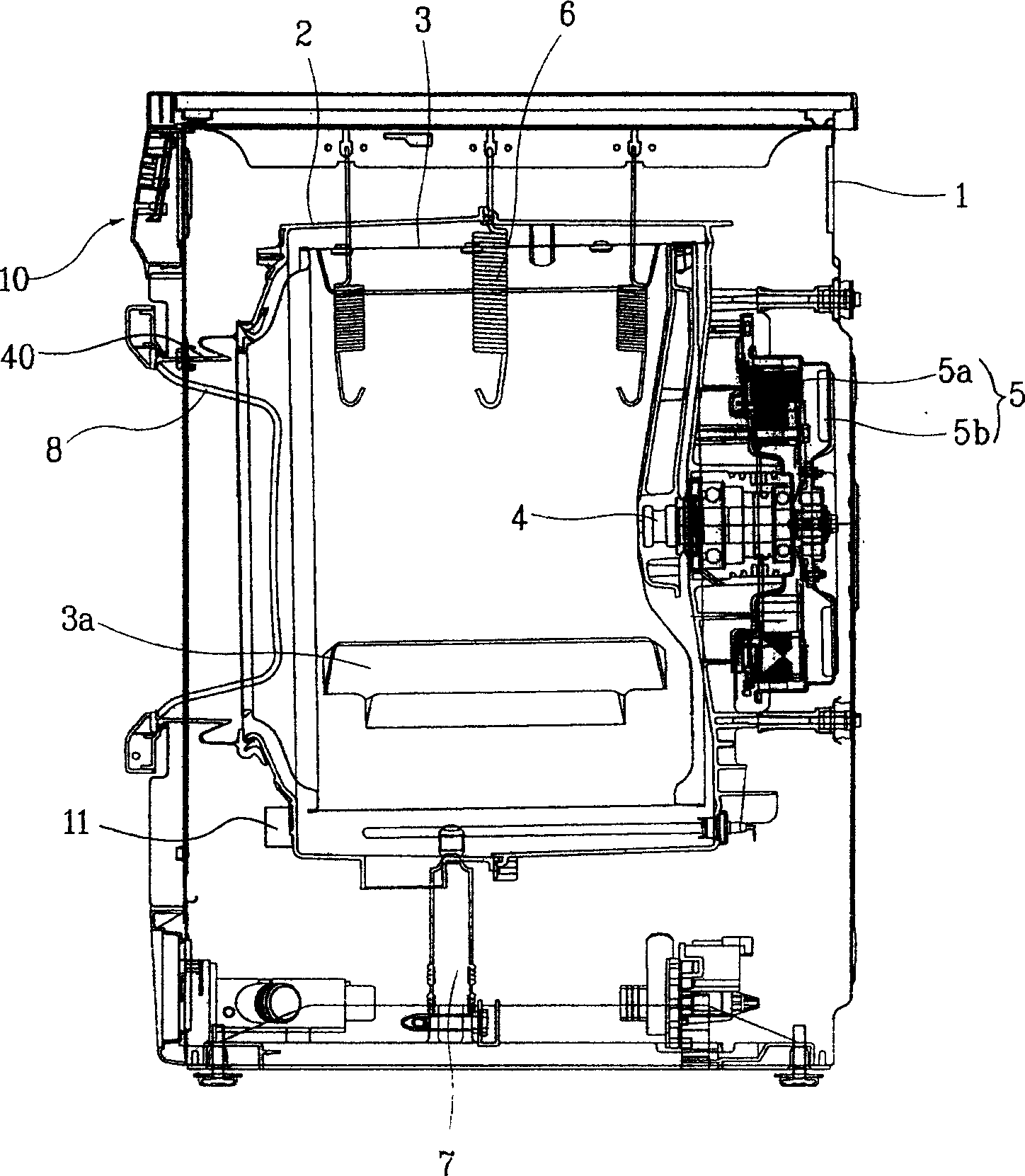

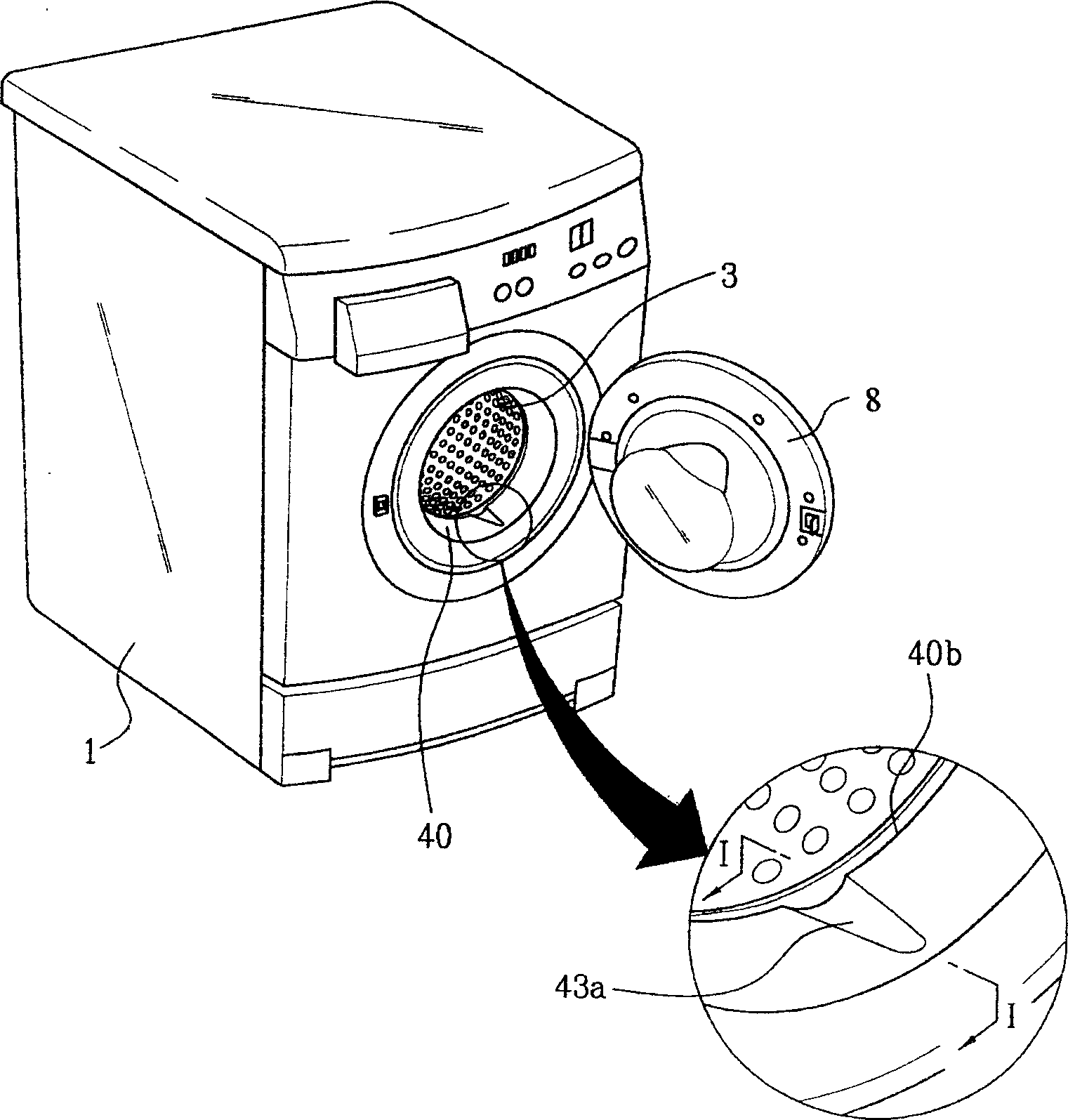

[0028] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

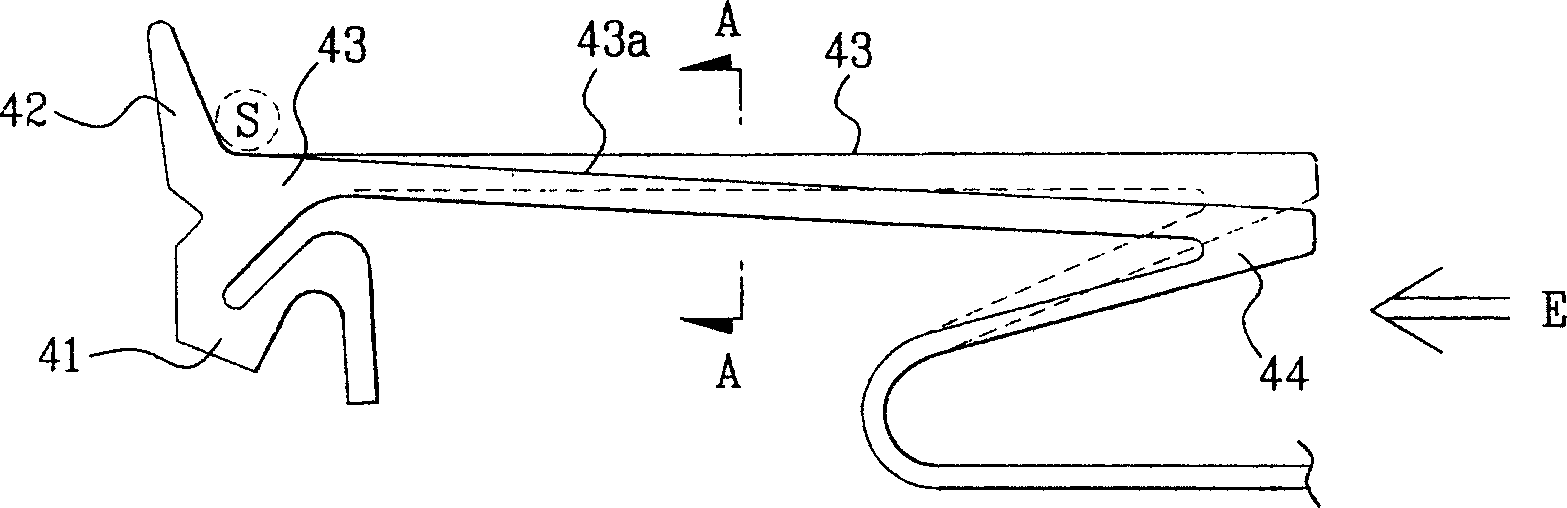

[0029] Such as Figure 5 , 6 As shown, when the gasket 40 of the drum washing machine of the present invention is installed on the drum washing machine, the inclined portion 43t is formed at the position where the water flow path groove 43a is formed at the lower end of the door 8. The inclined portion 43t is first from the existing at the end 42 The surface of the flat portion 43 initially has a certain height D, and then has a certain length L1 from its height in the direction of the groove 43a. Compared with the prior art, the gasket of the present invention is thickened in a superimposed manner.

[0030] Such as Figure 7 As shown, the inclined portion 43t is formed by extending a certain length X to the left and right with the center of the groove 43a as the center.

[0031] At this time, the structure of the inclined portion can also adopt a str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com