Thermal contraction inflation continuous expanding method and expanding device

A heat-shrinkable tube and gas-assisted technology, which is applied in the processing field of radiation-crosslinked heat-shrinkable tubes, can solve problems such as low production efficiency and poor product quality, and achieve the effects of improving production efficiency, small longitudinal shrinkage, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

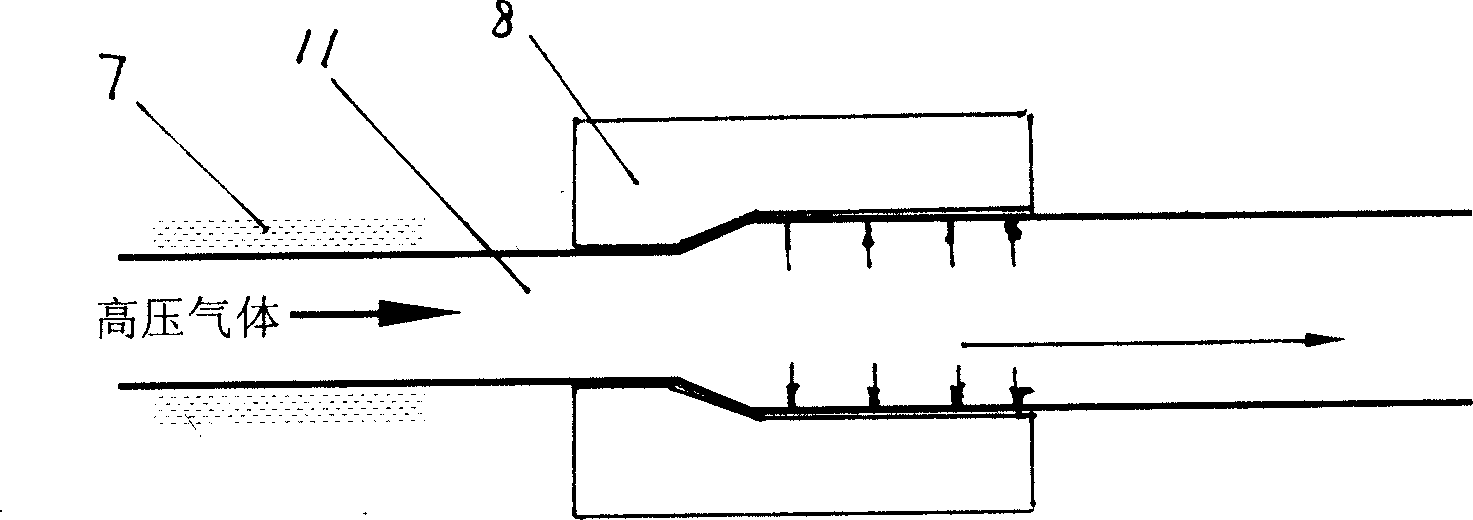

[0012] according to figure 1 As shown, using the principle of high-pressure gas-assisted forming, heat the heat-shrinkable tube at 80-120°C, feed the material at a speed of 2-10 m / min, and introduce high-pressure gas of 0.03-0.05 Mpar to be inflated and formed by high-pressure gas in the expansion mold. After cooling and shaping treatment at 10-25°C, the expansion production process of the heat-shrinkable tube is completed through heating, expansion, cooling, and traction.

Embodiment 2

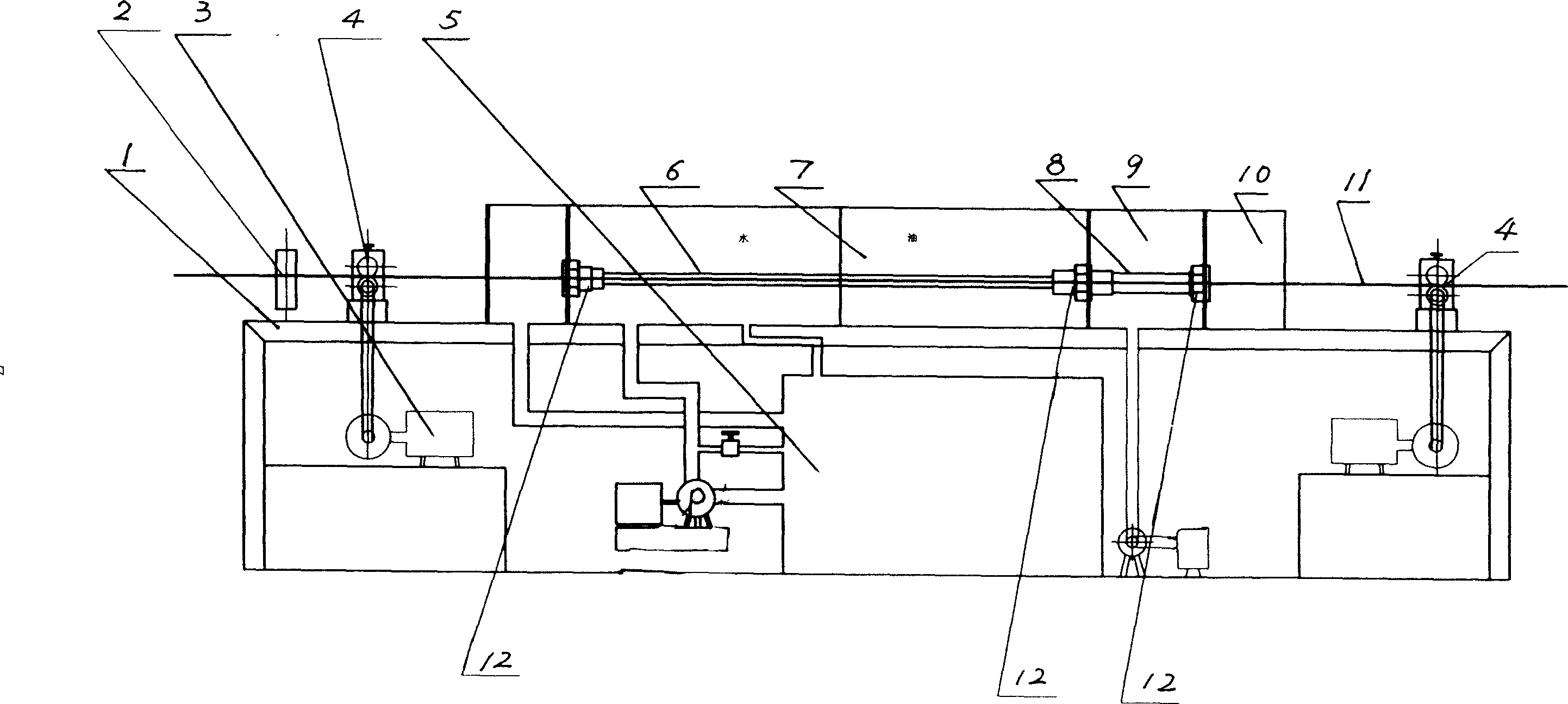

[0014] On the platform 1 of the continuous expansion machine, a guide roller 2 for heat-shrinkable tubing is provided, and a traction mechanism 4, a water bath box 6, an oil bath box 7, an expansion mold box 9, and a cooling and setting room 10 are arranged in sequence between them, wherein the motor 3 and The traction guide mechanism 4 is connected to drive the heat-shrinkable tube 11 to feed materials. The water bath box 6 and the oil bath box 7 are provided with heating devices, and the heat-shrinkable tube 11 can be heated in a gradient in the box. Pipe expansion mold 8, both ends are sealed and connected with oil bath box 7 and cooling and shaping room 10 through sizing outlet connector 12, control mechanism 5 controls water bath box 6, oil bath box 7 and traction mechanism 4 through corresponding lines End connection, control the feeding of heat shrinkable tubes, heating of water and oil baths, and gas-assisted molding of high-pressure gases.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com