Carton with overlapped base panels and blank therefor

A technology of packaging boards and cartons, which is applied in the direction of containers, packaging, transportation and packaging with multiple items, and can solve the problems of destroying the integrity of packaging boards and cartons, detachment, lock tearing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

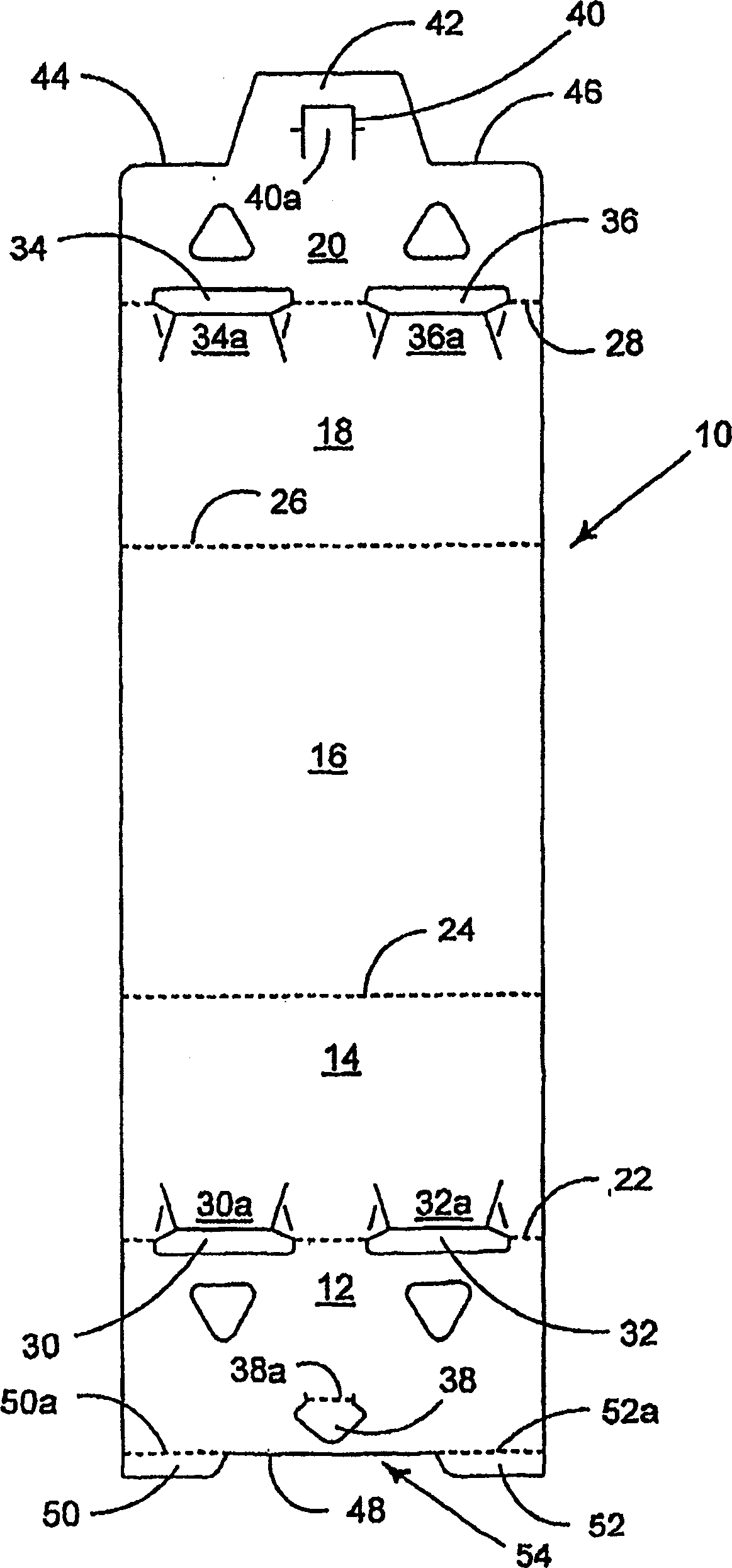

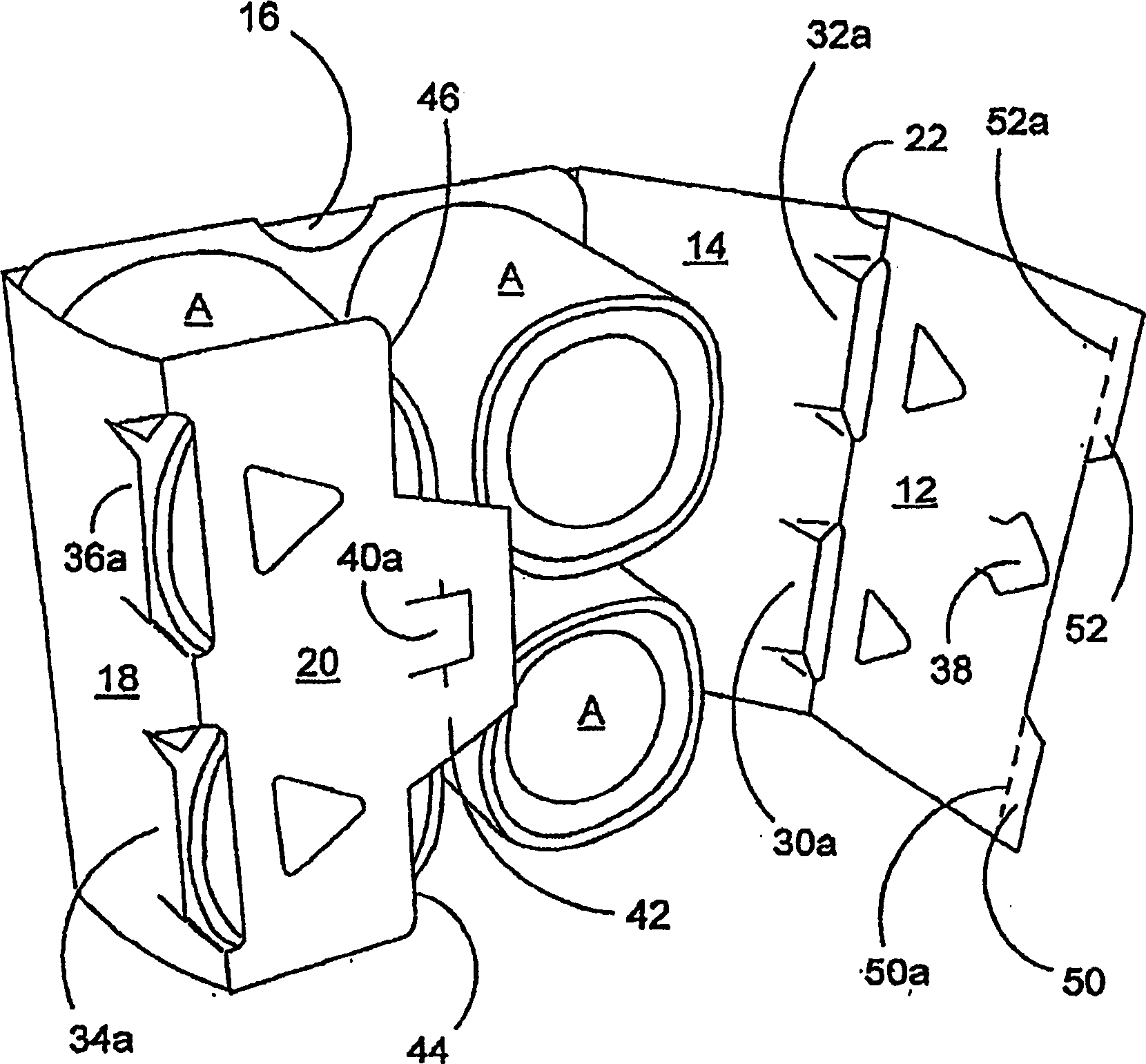

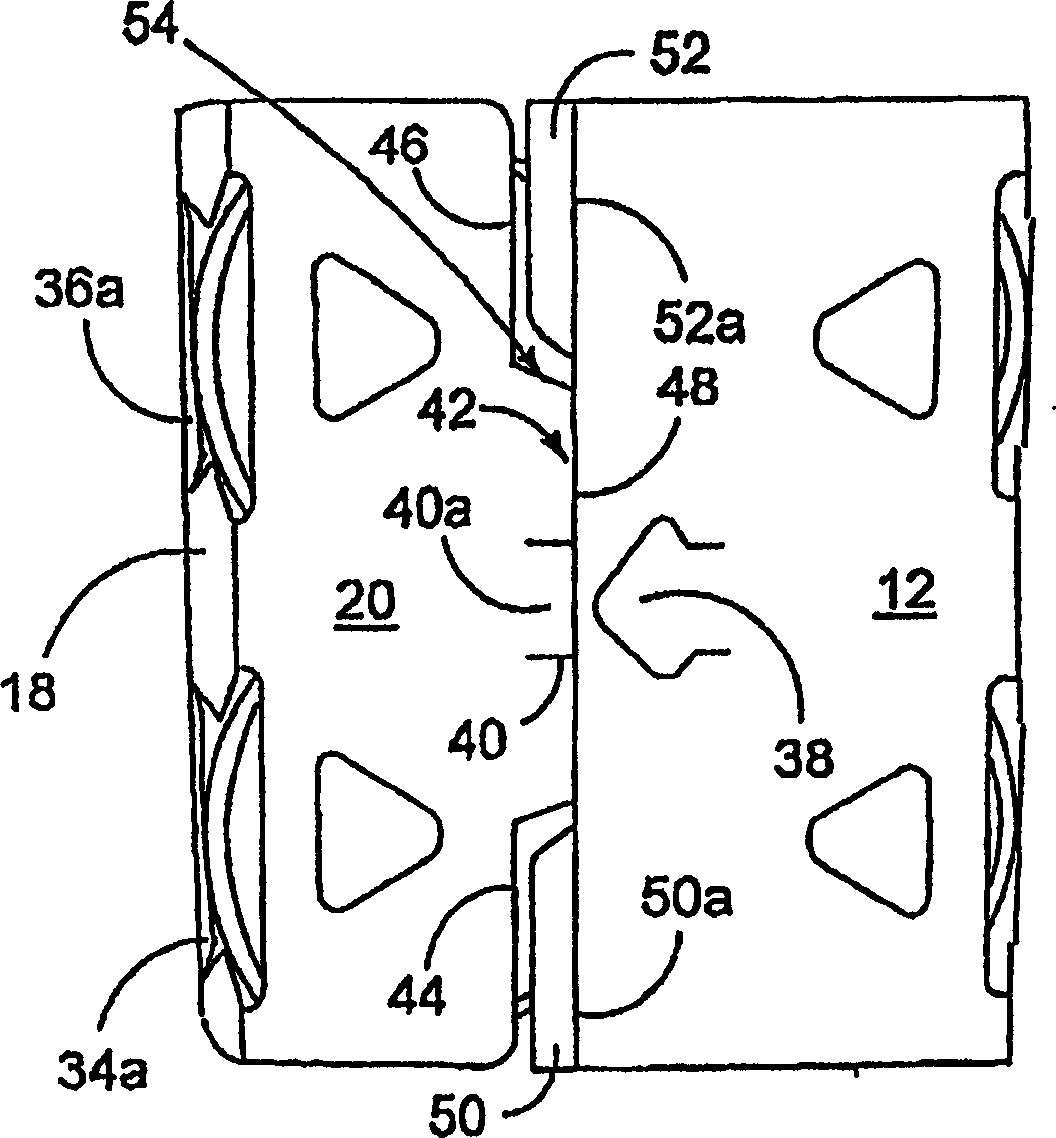

[0028] Referring to the accompanying drawings, especially figure 1 , shows a blank 10 formed from cardboard or board having a similar function. In this embodiment, the blank is of the well-known roll-to-roll type to be packaged around a set of containers, such as a set of cans "P" ( figure 2 ). The elongated blank 10 continuously comprises a first base panel 12, a first side wall panel 14, a top end panel 16, a second side wall panel 18, and a second base panel 20 along successive transverse fold lines 22, 24, 26 and 28, respectively. hinged to each other.

[0029] In one embodiment, bottom retaining holes are formed in the first bottom panel 12 and first side wall panel 14 along the transverse fold line 22 in part in order to prevent the forward movement of the item when it is received in the sleeve formed from the blank. 30, 32. The bottom holding holes are reinforced by hinged tabs 30a, 32a respectively. Similar bottom retaining holes 34 , 36 are partially formed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com