Sintered artificial decoration plate

A decorative plate, artificial technology, applied in building construction, covering/lining, construction, etc., can solve the problems of exposed bottom plate, unsightly, chipping and notch decoration, etc., to achieve the effect of convenient purchase and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

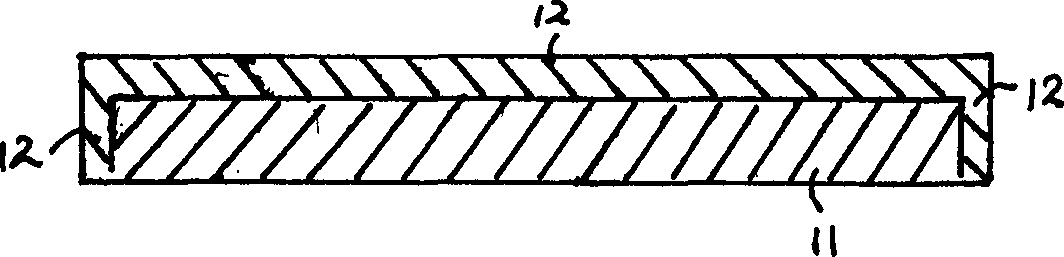

[0020] Refer to attached figure 1 . The present invention includes a substrate 11 and a decoration layer 12, which has four sides and is rectangular in shape, and the decoration layer extends to all sides of the board to completely cover the sides of the substrate.

[0021] figure 1 The decorative layer is shown on two sides, and the other two sides are in the same condition as the two sides shown in the picture.

Embodiment 2

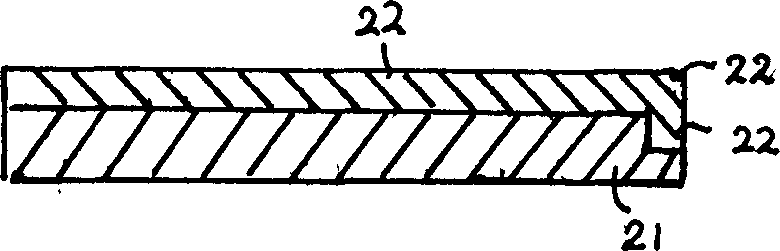

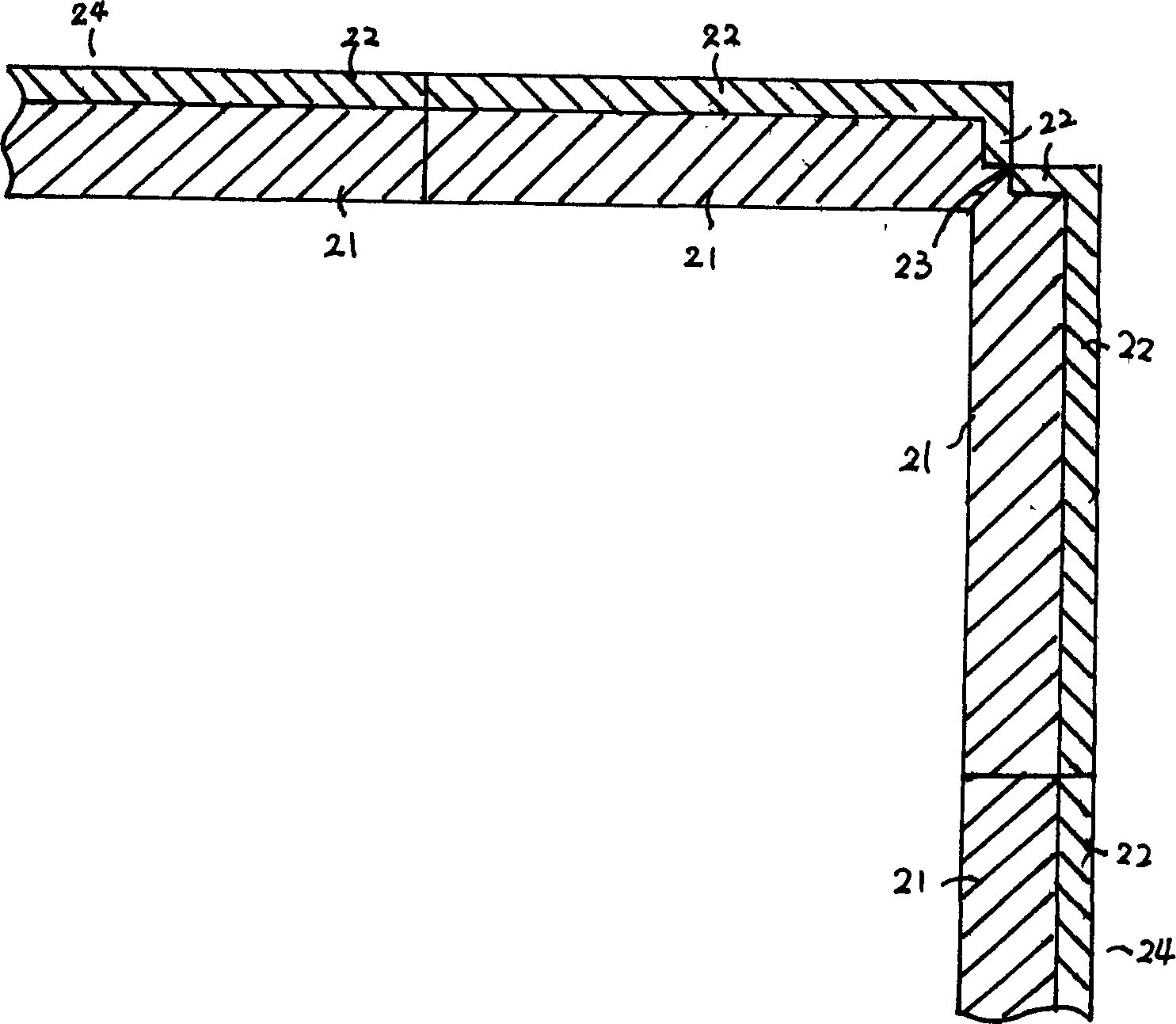

[0023] Refer to attached figure 2 and 3 . The present invention includes a substrate 21 and a decoration layer 22, the decoration layer extends to one side of the board, and does not completely cover the side of the substrate.

[0024] The incision begins at the exposed start site 23 of the substrate. Reference numeral 24 is a common decorative plate.

Embodiment 3

[0026] Refer to attached Figure 4 and 5. The present invention includes a substrate 31 and a decoration layer 32, which has four sides and is rectangular in shape, and the decoration layer extends to the two sides of the board to completely cover the sides of the substrate.

[0027] Figure 5 is a schematic diagram of docking, which is not inscribed. Reference numeral 33 is a common decorative plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com