Cathode-ray tube hopper package

A cathode ray tube and packaging technology, applied in the direction of cathode ray/electron beam tube shell/container, type of packaging items, special packaging items, etc., can solve problems such as weak support rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

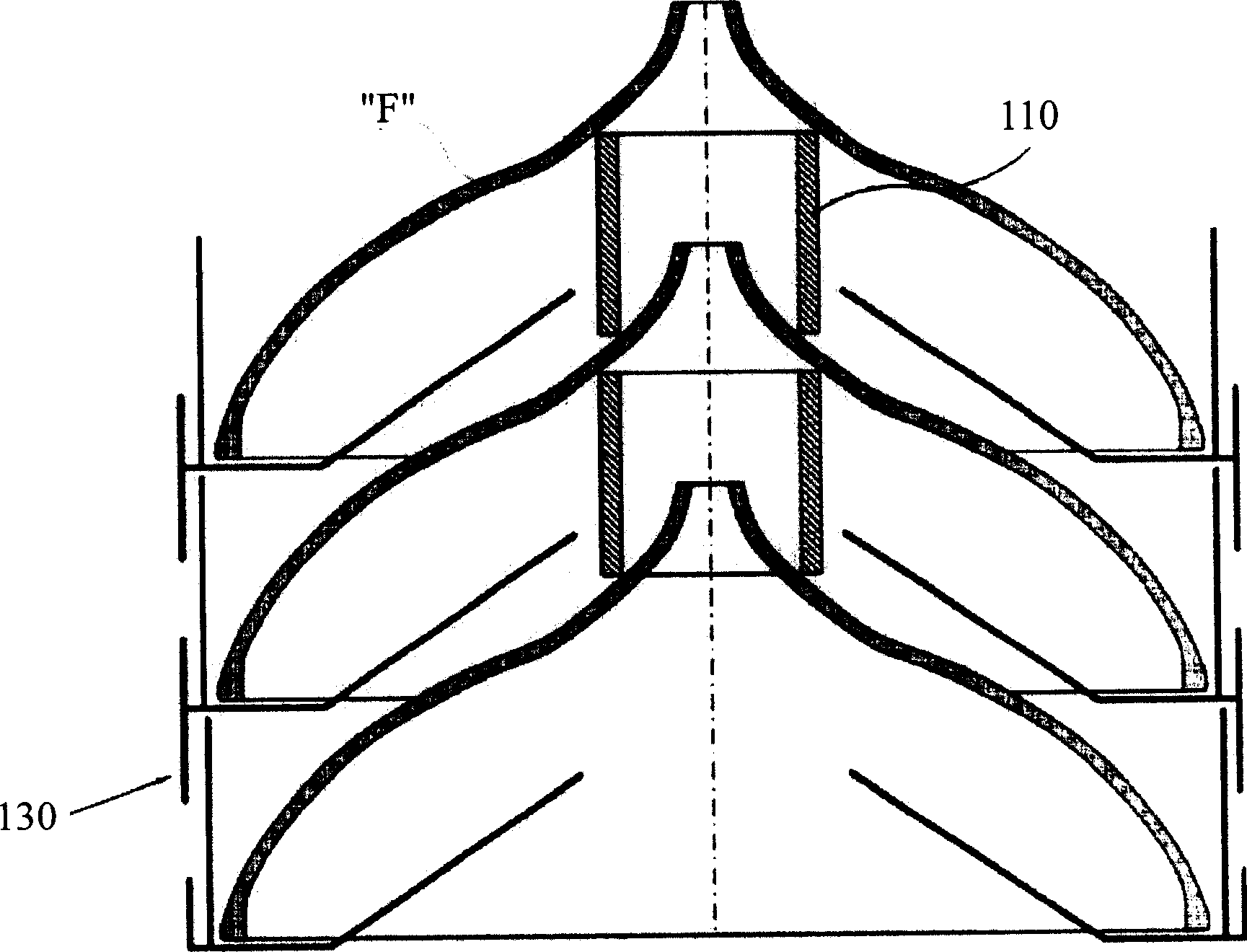

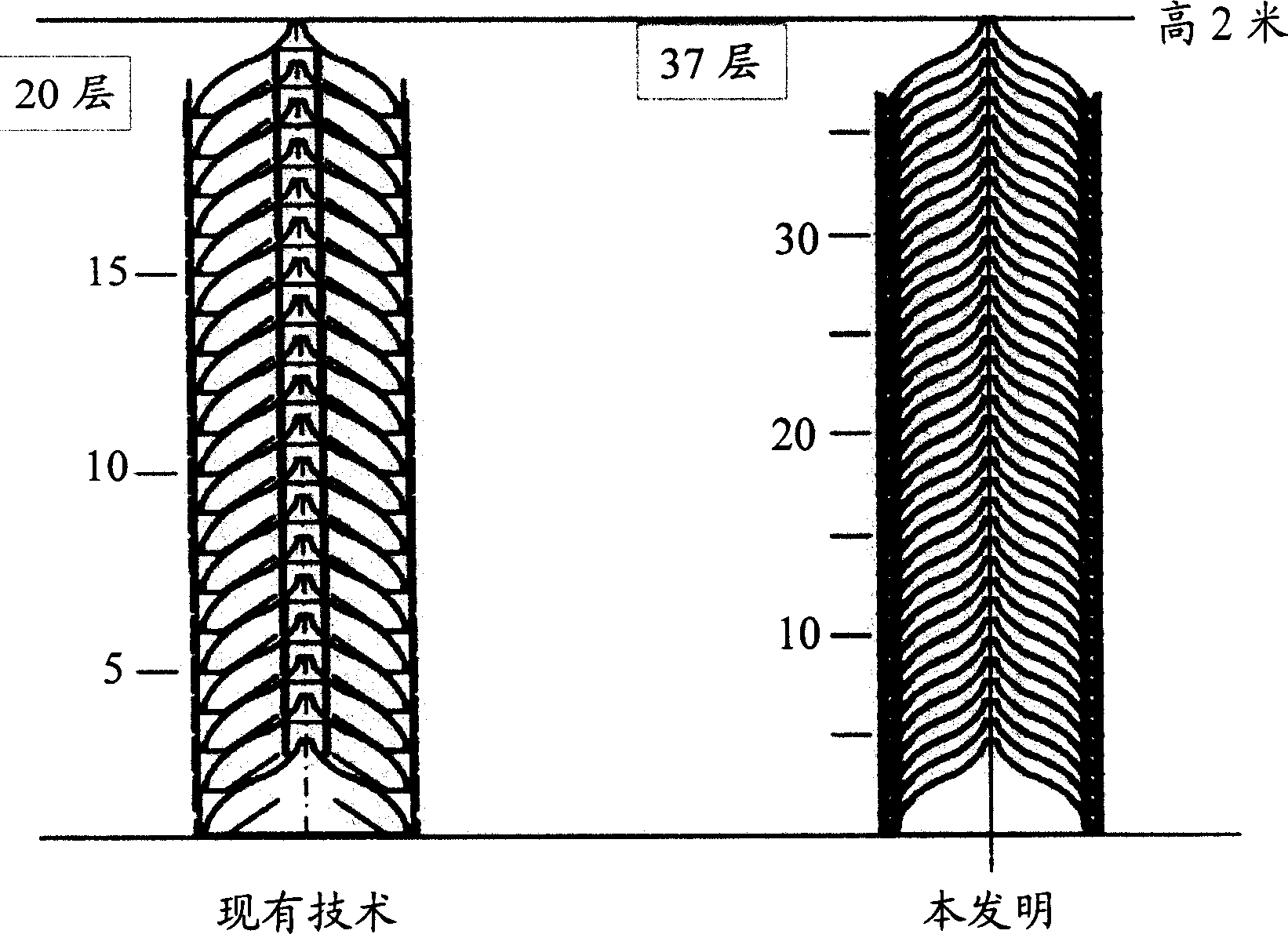

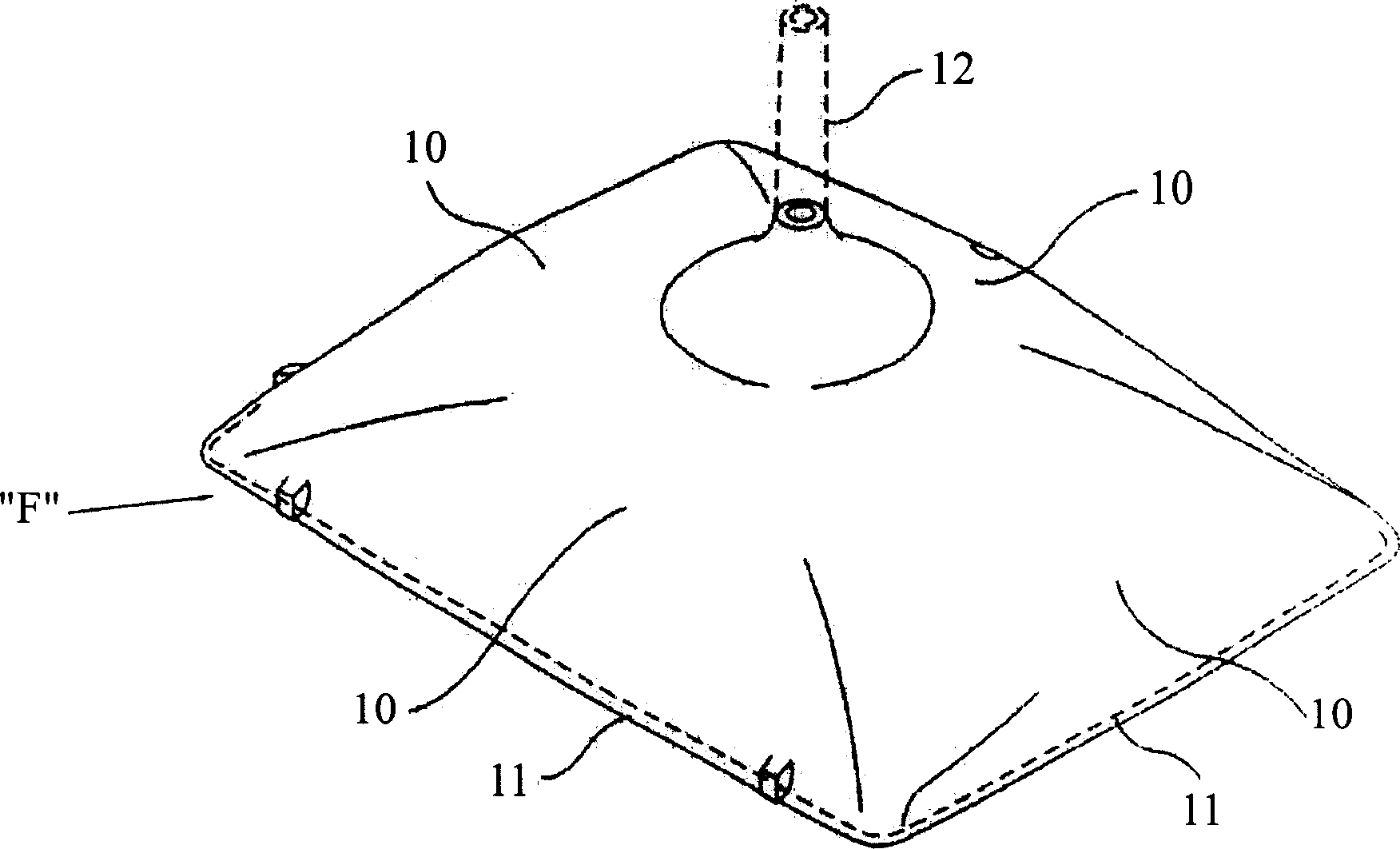

[0046] Figure 3a and Figure 3b Schematic diagrams of the front and back of the funnel, respectively. As shown in the figure, the funnel F, which is a part of a cathode ray tube (CRT), is a funnel-shaped glass product connected to the rear of a panel (Panel, not shown).

[0047] The funnel F almost all forms a quadrilateral, including a flat bottom surface 11 at the end and a funnel-shaped inclined surface 10 bent from each side of the bottom surface 11 toward the center. An anode cap (Anode Button) not marked with reference numerals is attached to the ramp 10 . The central area of the bevel 10 will join with the electron gun neck 12 (Neck) indicated by the dotted line in the figure. As mentioned above, the packages 30 , 31 , 32 , , , are used to package the funnel F excluding the electron gun neck 12 .

[0048] Figure 4a and Figure 4b The front and back schematic diagrams of the cathode ray tube funnel package according to the first embodiment of the present invent...

no. 2 example

[0073] Figure 9a and Figure 9b The placement states of the cathode ray tube funnel packages according to the second embodiment of the present invention are shown respectively.

[0074] The pallet used to support the goods in the general container ( Figure 8 The size of the lower wood part) is constant. Therefore, on this pallet as a benchmark, stack the packages 40-43 on a pallet and pack the funnel F. In order to make the packages 40-43 mutually detachable, a design is also made on the side wall 1. Has a concave-convex snap-fit structure.

[0075] refer to Figure 9a One of the packages 40 has a concave-convex fastening structure on four sides, and its shape can be any one of the convex parts 51a, 51b, and the concave parts 52a, 52b.

[0076] The sidewalls 1 of the packages 40-43 are designed with alternately arranged convex parts 51a, 51b and concave parts 52a, 52b, so that the adjacent packages can be linked horizontally, so that they can be packaged in 4 packages...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com