Compatible and accurate calibration method for double eye line structure photo-sensor and implementing apparatus

A line-structured light and calibration method technology, applied in the direction of optical devices, measuring devices, instruments, etc., can solve problems such as difficult to reach, difficult to extract pixel coordinates of feature points, complex target shape, etc., to achieve accurate calibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and examples.

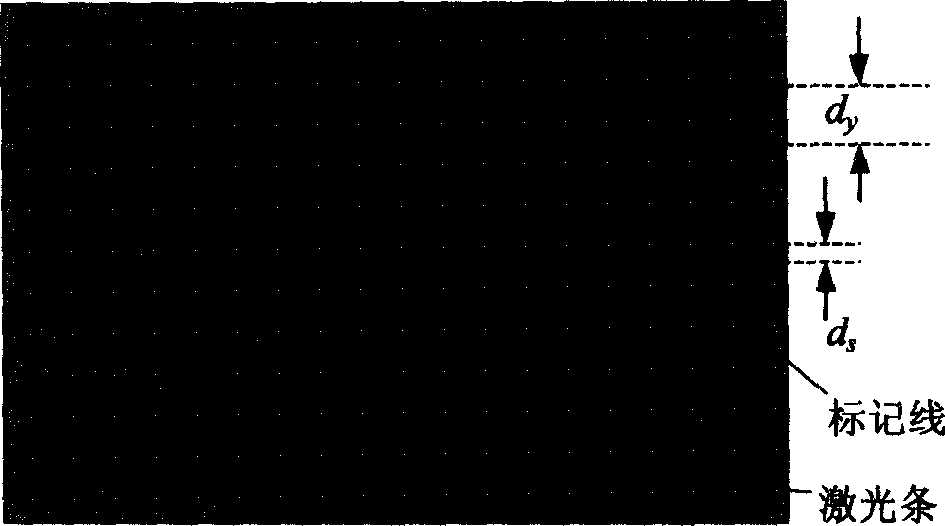

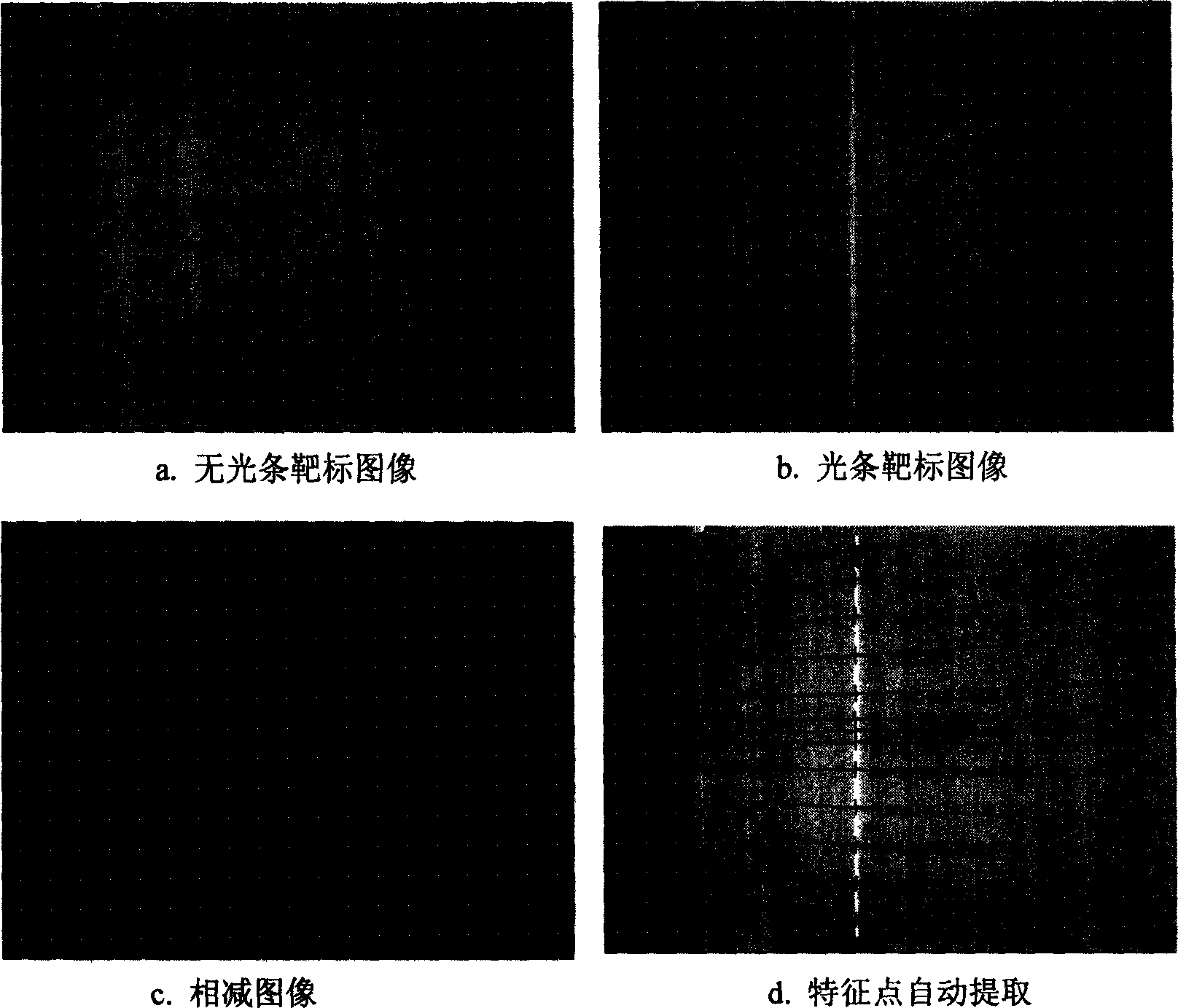

[0026] figure 1 It is a new type of parallel linear array planar target designed by us. The target is to accurately describe a group of horizontal array straight lines on the plane plate, and the distance between the straight lines is fixed as d y , there are two other parallel straight lines on both sides of a straight line in the middle with a distance of d s , and d s y , defining it as a marked line. Such as figure 2 As shown, the target is fixed on a moving guide rail during calibration, and the target plane is perpendicular to the moving direction of the guide rail through adjustment, and the guide rail is adjusted to ensure that the target plane is perpendicular to the projection laser plane. The laser is projected onto the target surface to generate a light strip, and the light strip is adjusted to ensure that the light strip is perpendicular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com