Method and apparatus for picking up work piece and mounting machine

一种拾取装置、安装机的技术,应用在电气元件、电气元件、电固体器件等方向,能够解决拾取装置结构复杂等问题,达到控制过程容易、制造工艺简单化、定位操作容易的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

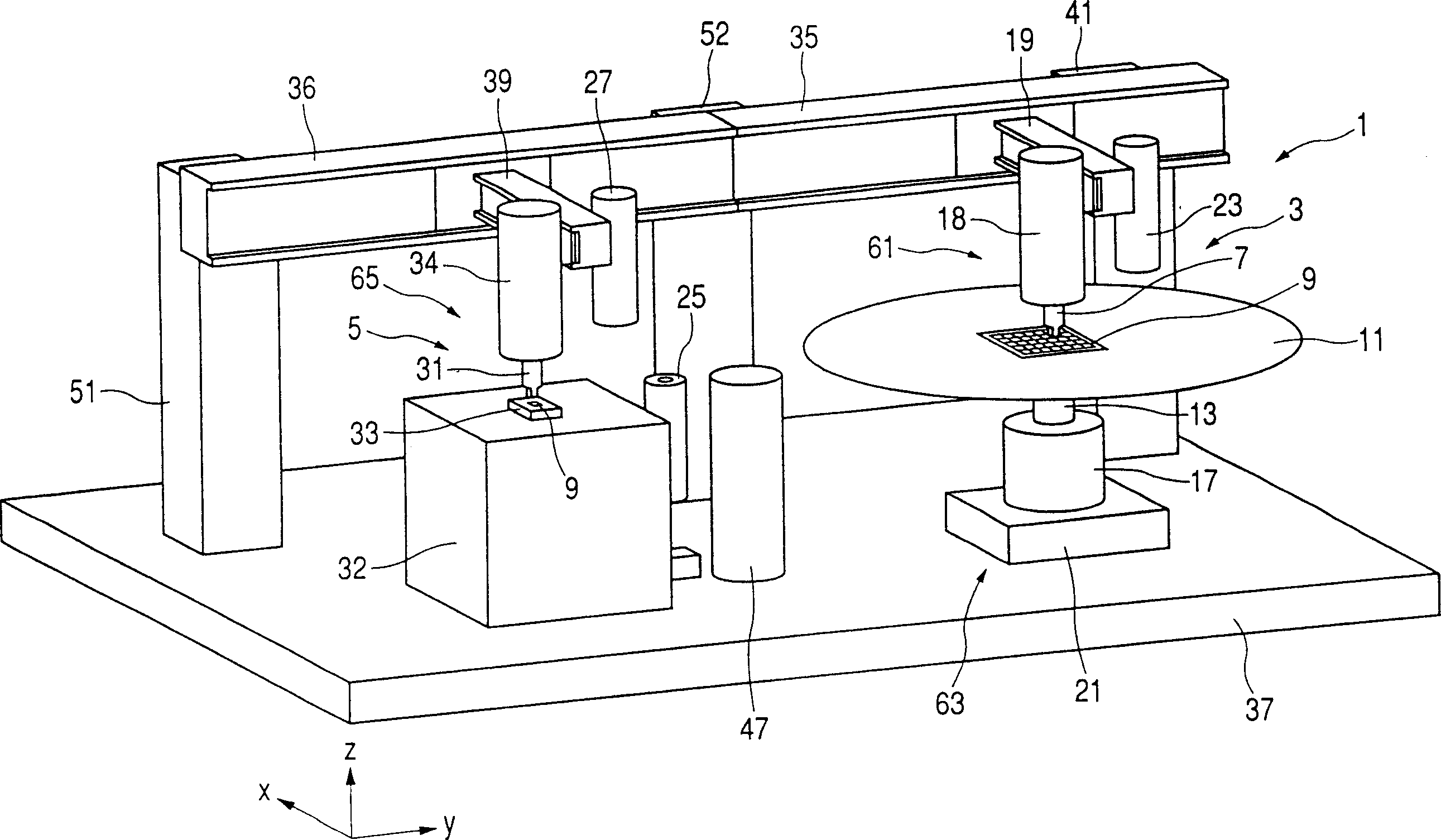

[0038] Hereinafter, the best mode of the mounting machine according to the present invention will be described with reference to the accompanying drawings.

[0039] figure 1 A perspective view showing the mounting machine 1 is shown. This mounting machine 1 is made up of pick-up device 3 and mounting device 5, and described pick-up device is used for a workpiece 9 such as a semiconductor chip is detached from an adhesive board 11 and transfers it, and described mount device is used for workpiece 9 Mounted on a component for mounting (mounted component) such as a printed circuit board 33 .

[0040] The pick-up device 3 is arranged on the upstream side of the base 37 of the mounting machine 1 (ie figure 1 the right side of the middle), and the mounting device 5 is arranged on the downstream side of the base 37 (ie figure 1 left in ). In addition, a temporary placement table 47 is provided on the base 37 at a position between the pick-up device 3 and the mounting device 5,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com