Three dimensional collinear measuring ring for drillhole inclination survey and axial deformation

A technology of axial deformation and measuring ring, applied in the direction of mechanical solid deformation measurement, etc., can solve the problems of inability to cross use, high price, increased workload and monitoring costs, etc., and achieve the effect of convenient layout design and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

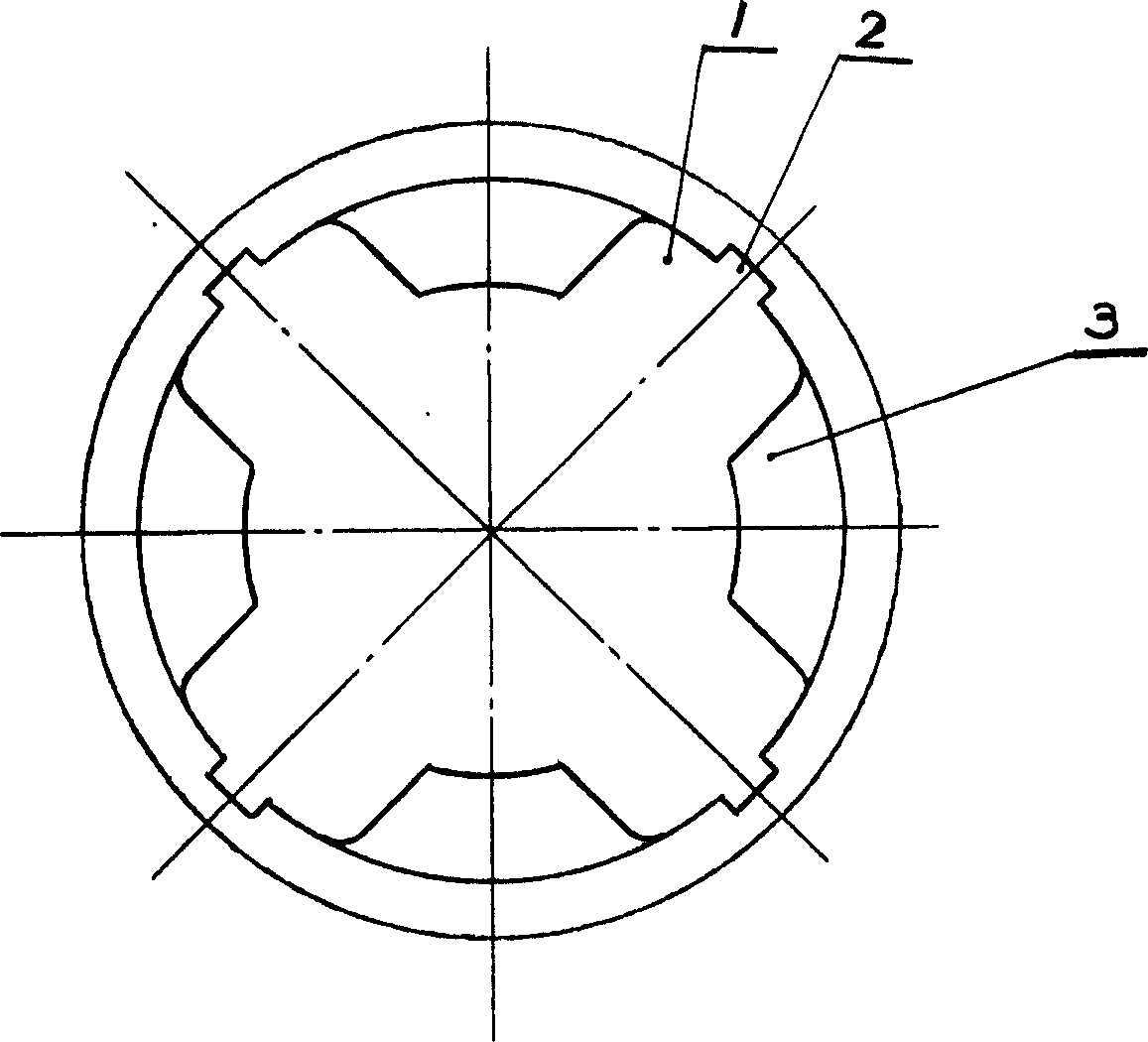

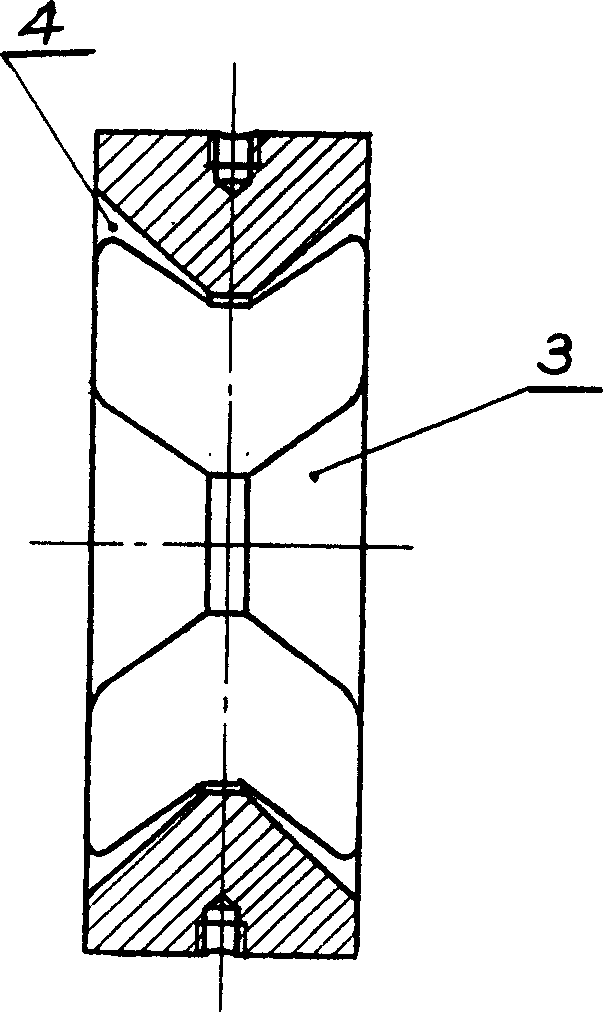

[0025] Depend on figure 1 It can be seen that the three-dimensional collinear measurement ring for drilling inclinometer and axial deformation is a ring made of hard materials such as steel, hard aluminum alloy, and hard plastic with an outer diameter of 70 mm, an inner diameter of 42 mm, and a thickness of 23 mm. There are four pairs of guide chain chute 1 evenly distributed on the inner wall of 20 mm wide and 9 mm deep. The width of the guide chain chute 1 just matches the thickness of the guide chain of the sliding deformation gauge. The distance between the bottom just matches the width of the guide chain of the sliding deformation gauge, and the guide chain can slide directionally along the guide chain chute 1 of the three-dimensional collinear measurement ring; the four guide chain chute 1 form four protrusions 3 distributed in the shape of cross petals, The sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com