Tail-gas purification system and method

An exhaust gas purification and exhaust gas technology, which is used in the treatment of ash accumulated on a particulate filter, the exhaust gas purification field of internal combustion engines, and can solve problems such as increasing exhaust pressure, reducing the capacity of diesel particulate filter, and reducing filter area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

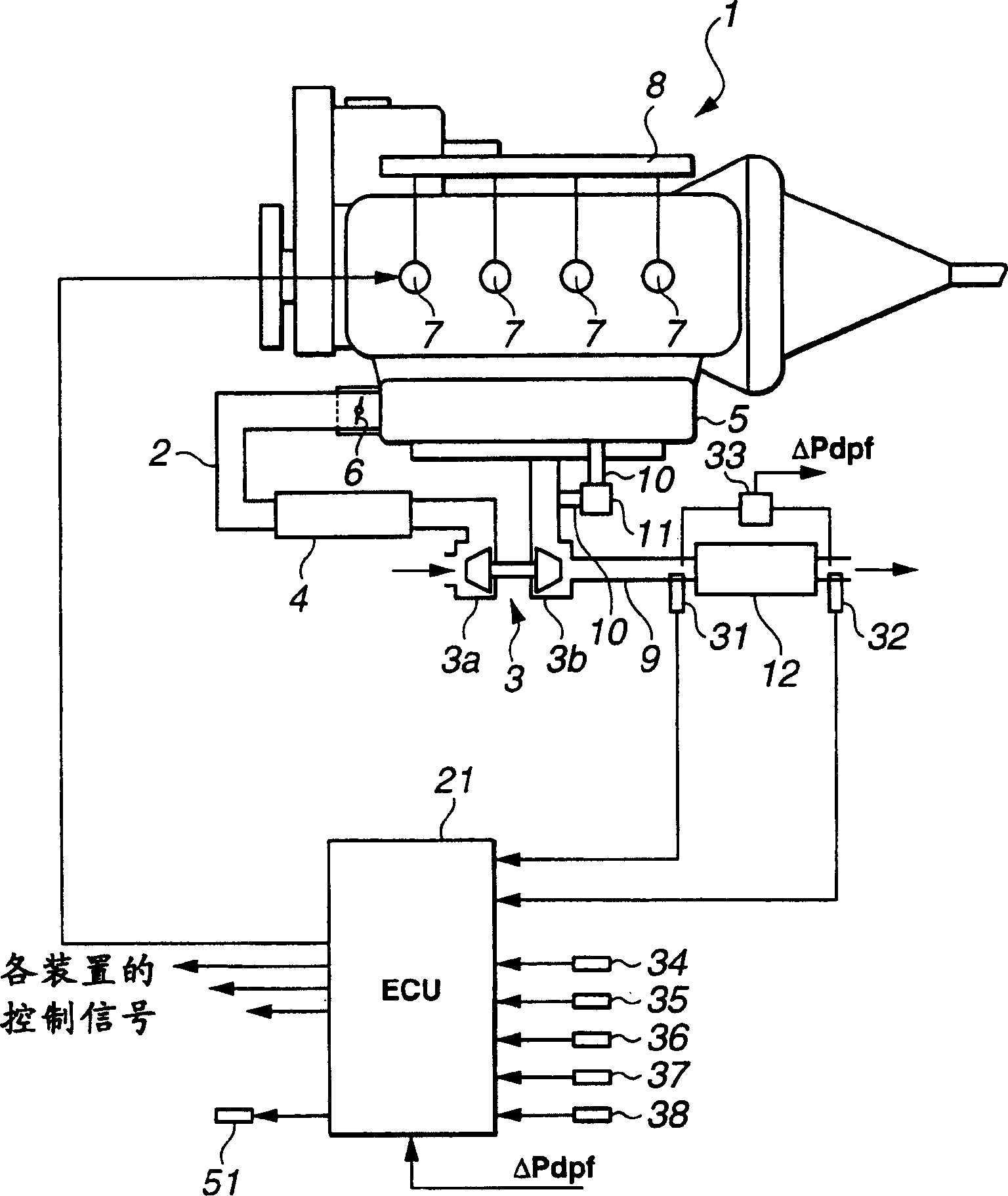

[0022] first reference figure 1 , represented by 1 direct injection diesel engine (hereinafter referred to as engine).

[0023] The engine 1 includes an intake passage 2 having an air cleaner (not shown) at an inlet portion thereof by which dust contained in intake air is removed. A compressor section 3a of a variable nozzle turbocharger (hereinafter simply referred to as a turbocharger) 3 is provided downstream of the air cleaner. The suction air passing through the air cleaner is compressed by the compressor section 3a and sent forward. Downstream of the compressor section 3a is provided an intercooler 4 by which the intake air sent forward from the compressor section 3a is cooled. In addition, a throttle valve 6 is provided immediately upstream of the buffer tank 5, so that cooled intake air flows through the throttle valve 6 into the buffer tank 5, and then is sent to each cylinder (not shown) through a manifold section (not shown). )middle.

[0024] The injectors are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com